Engineered fence pickets with ship lapped edges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

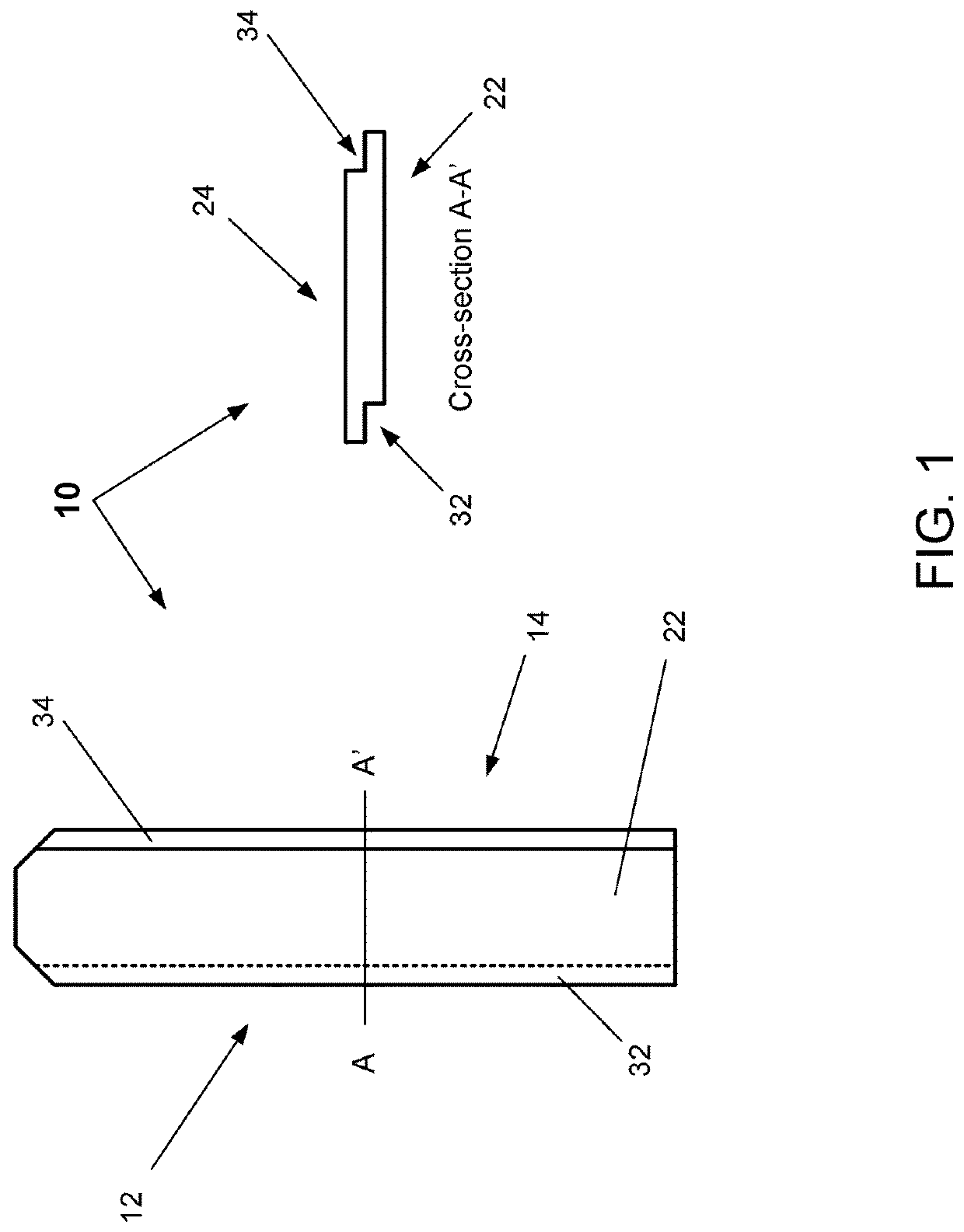

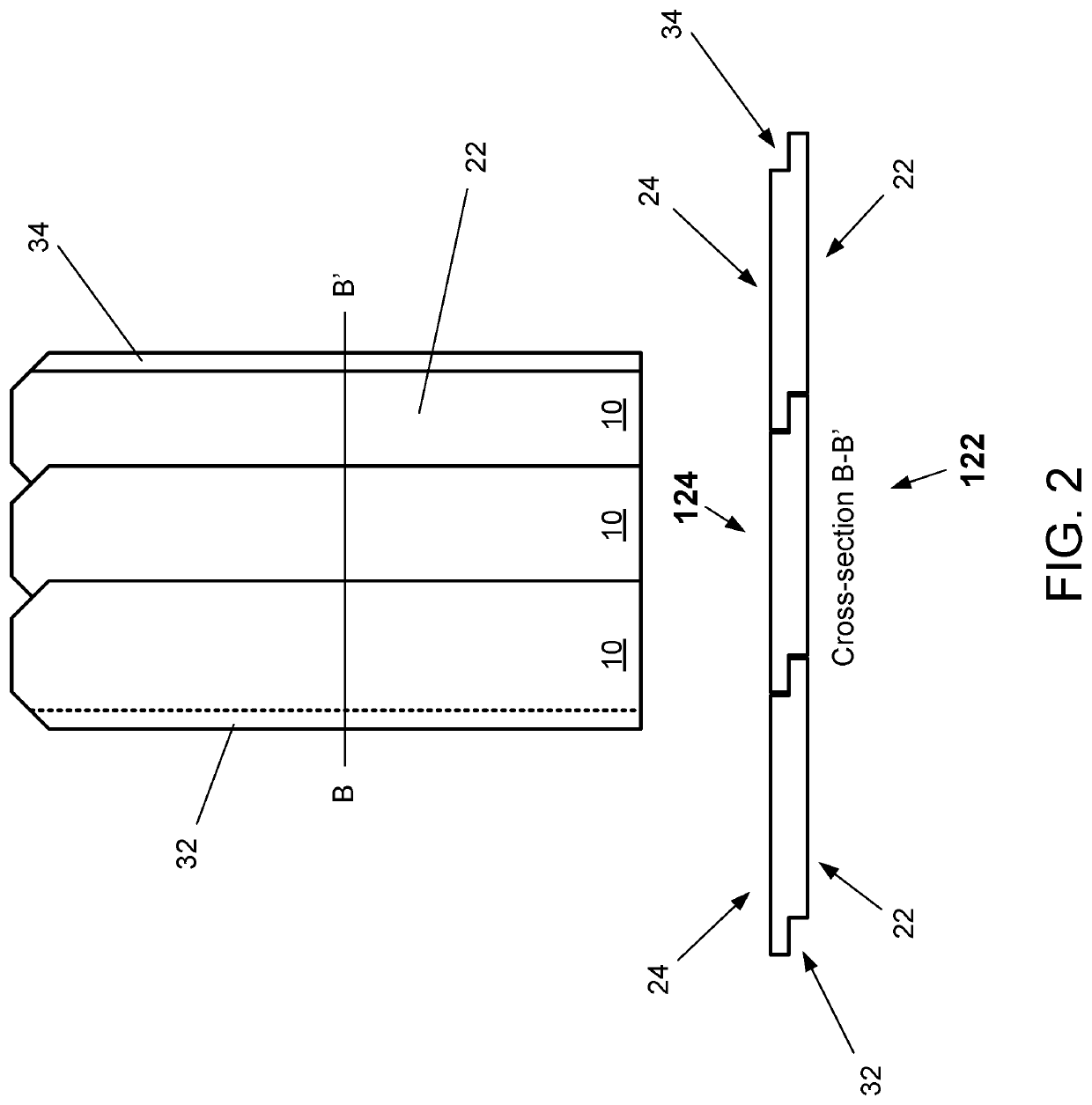

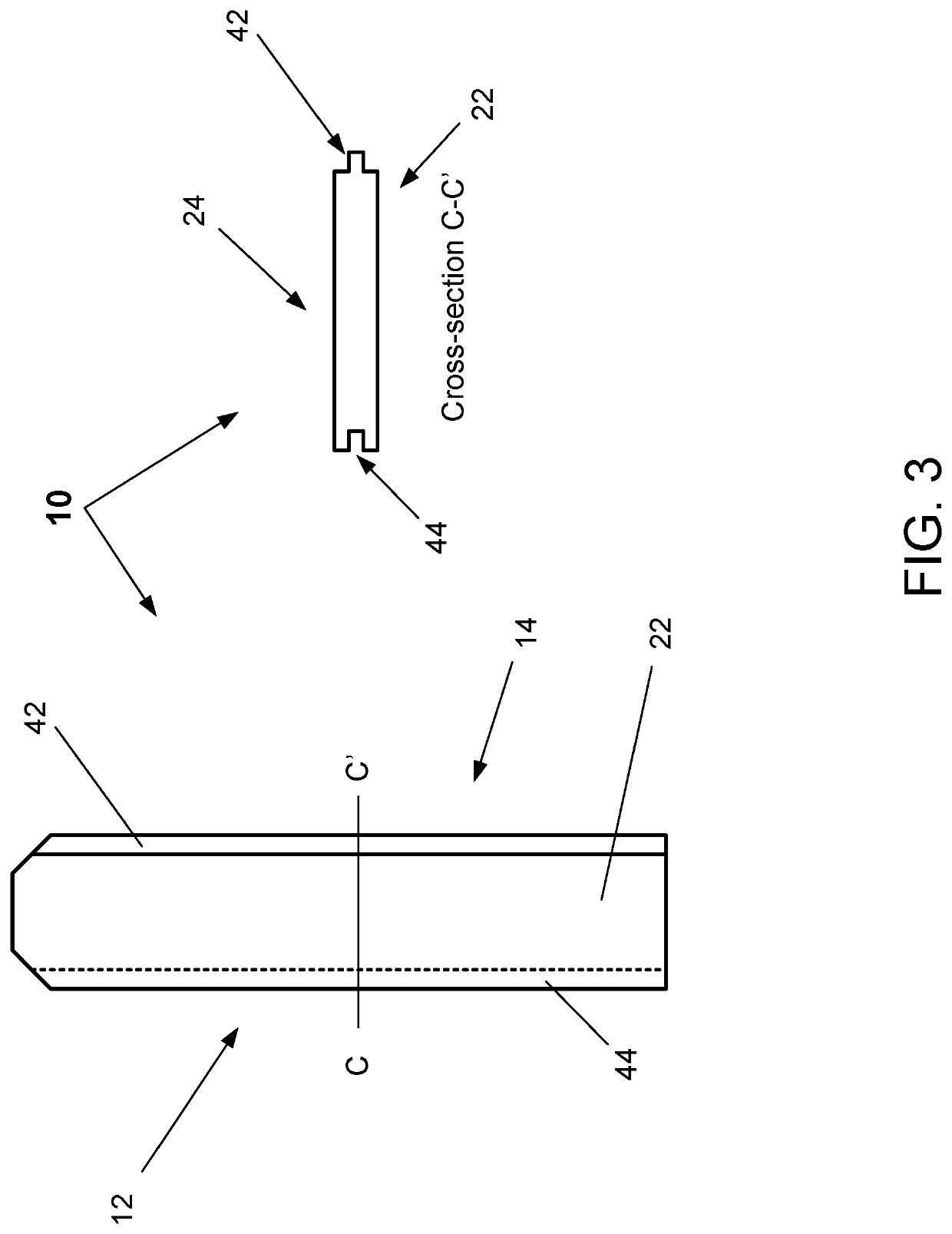

[0010]In various exemplary embodiments, the present invention comprises an engineered wood fence picket and system for manufacturing fence pickets using engineered wood products, including, but not limited to, oriented-strand board (OSB), laminated veneer lumber (LVL), fiber strand, and / or laminated strand lumber (LSL). The opposing right and left edges of each picket comprise corresponding elements of a joint, such as, but not limited to, a shiplap joint or tongue-and-groove joint. A fence or fence segment may be constructed by aligning a plurality of said fence pickets vertically or horizontally so that the edges of adjacent pickets mate or meet to form a joint. Engineered wood products provide the authentic look and appeal of real wood, but with the durability and workability of treated engineered wood, free of knots, voids and other defects found in natural wood.

[0011]Currently, the fencing industry uses solid lumber pickets for most residential applications. Solid wood pickets ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com