Cap for Containers with Improved Sealing

a technology for containers and caps, applied in the field of caps for containers with leaktight closures, can solve the problems of inadequate sealing and drawbacks of caps of this type, and achieve the effects of preventing loss, improving sealing, and reducing the weight of caps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023]Everything defined in this detailed description is provided to help fully understand the disclosure. Persons having ordinary skill in the art will therefore appreciate that variations, changes and modifications of the embodiments described in the present specification are possible without departing from the scope of the disclosure, so the designs and specific implementations presented in this document are provided solely for purposes of illustration and comprehension, and not for limiting the aspects of the disclosure in any way.

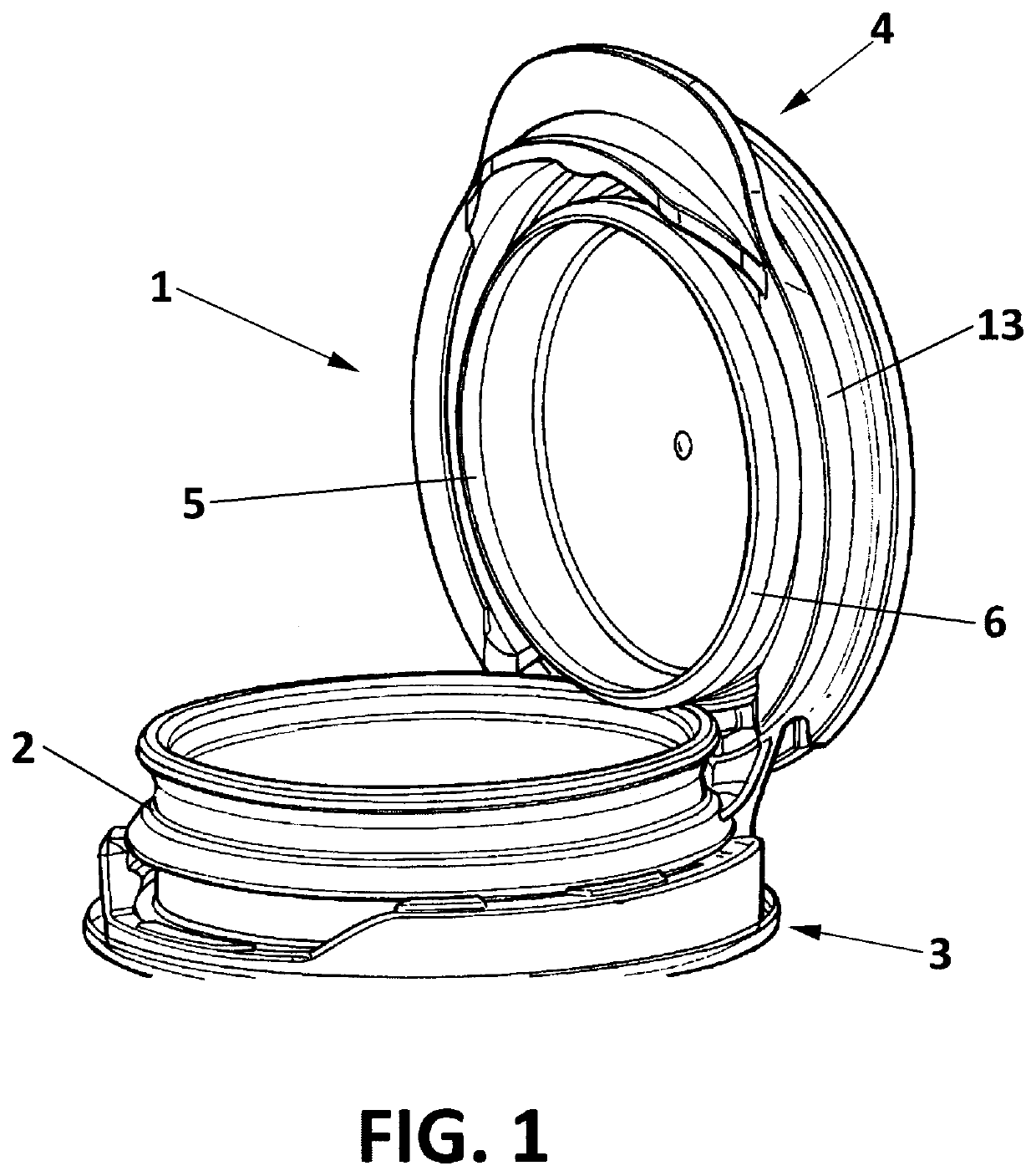

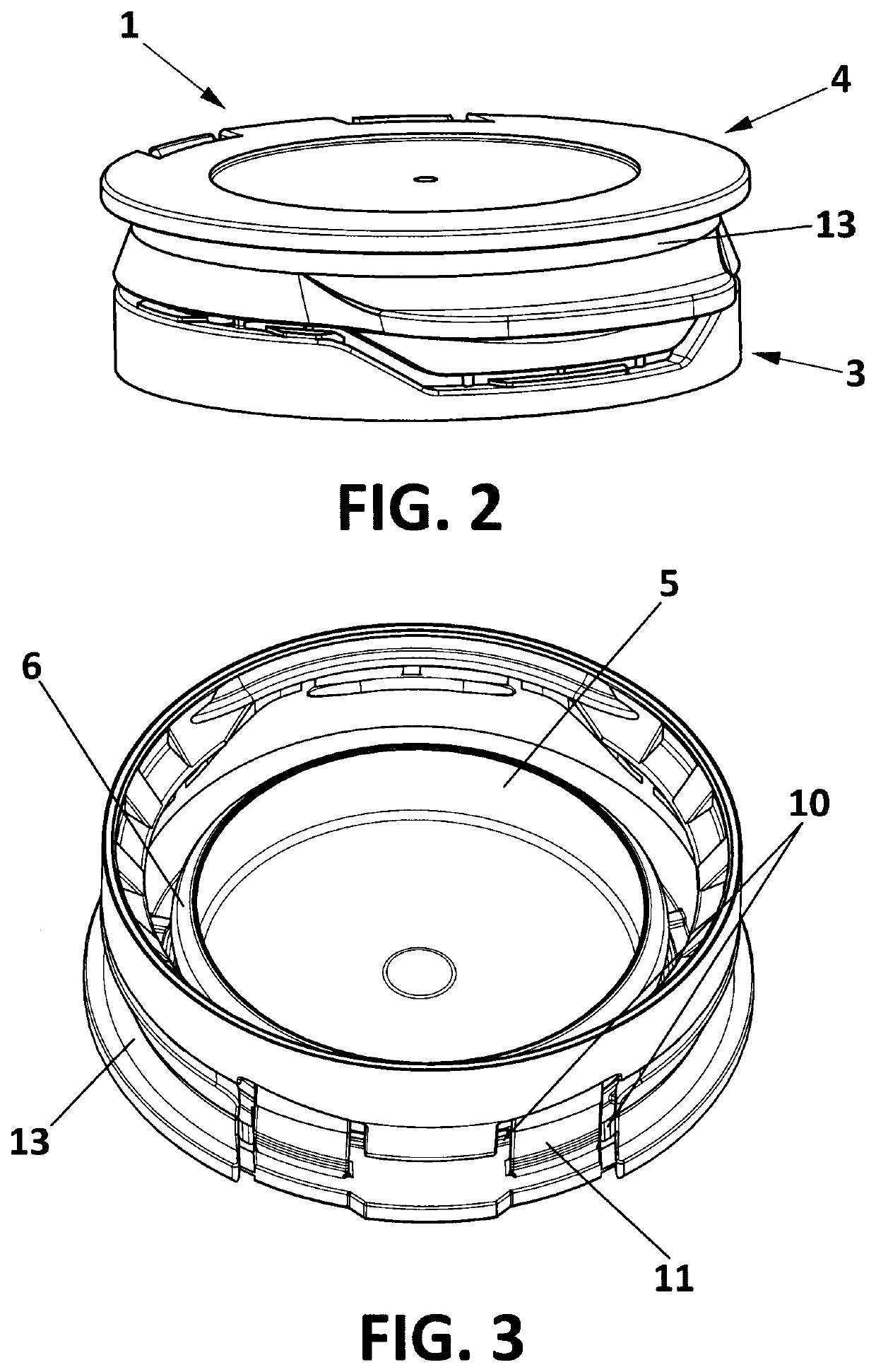

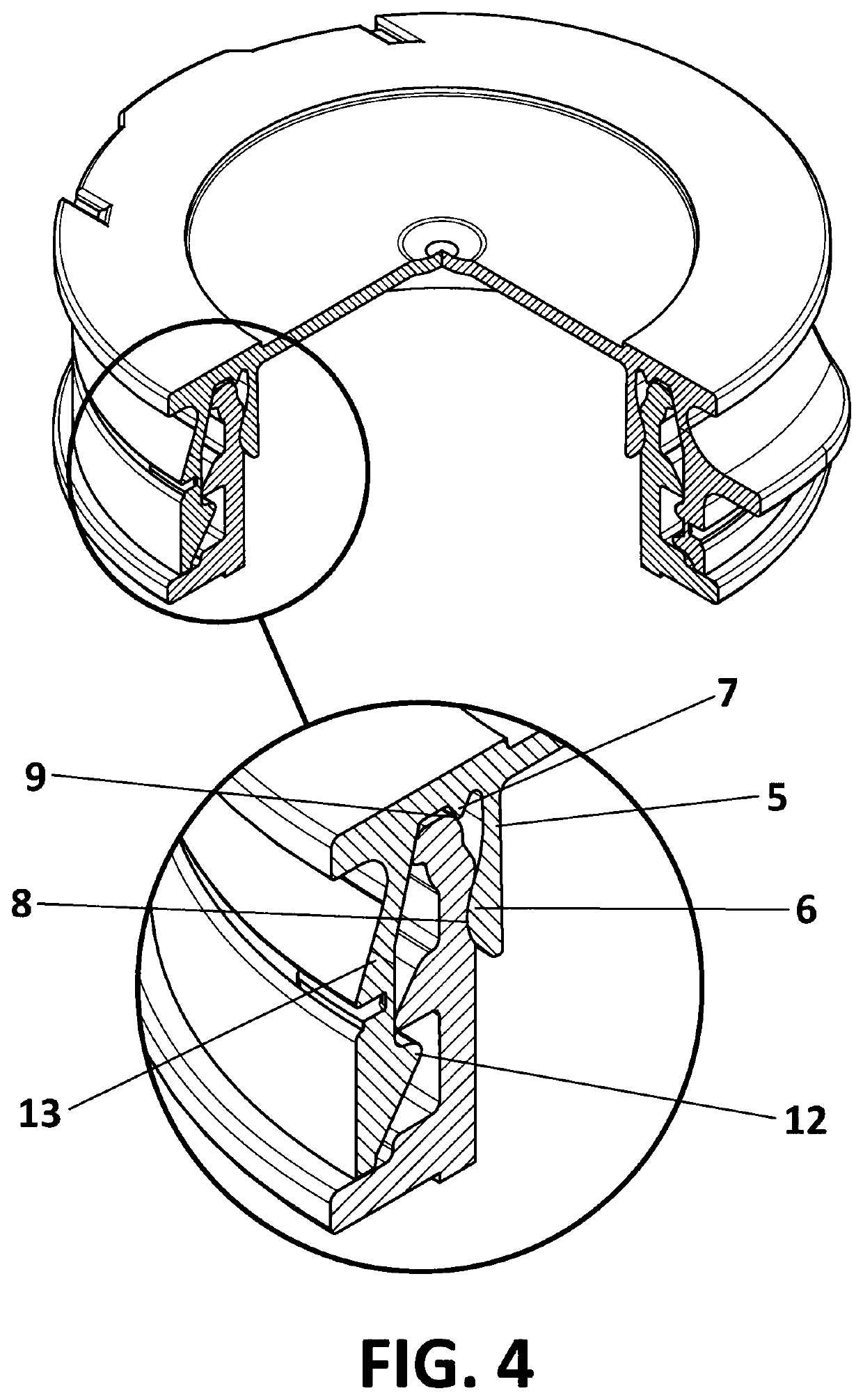

[0024]The present disclosure discloses a double-sealing solution for container caps which is based on a cap inner face configuration comprising a cylindrical skirt 5 and a rib 7, where the cylindrical skirt and the rib are sized for contacting the inner face of the neck (2) of a container and thereby creating two sealing areas.

[0025]This solution is applicable to any type of cap, but by way of example, a particular embodiment showing a cap having two p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com