Laundry system for smart garments

a technology for smart clothes and laundry systems, applied in dry-cleaning apparatuses, other washing machines, textiles and paper, etc., can solve the problems of accelerating the physical deterioration of garments, negative impact on the environment, and detergent corrosion, so as to enhance cleaning and exposure to cleaning and deodorizing agents, and facilitate agitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

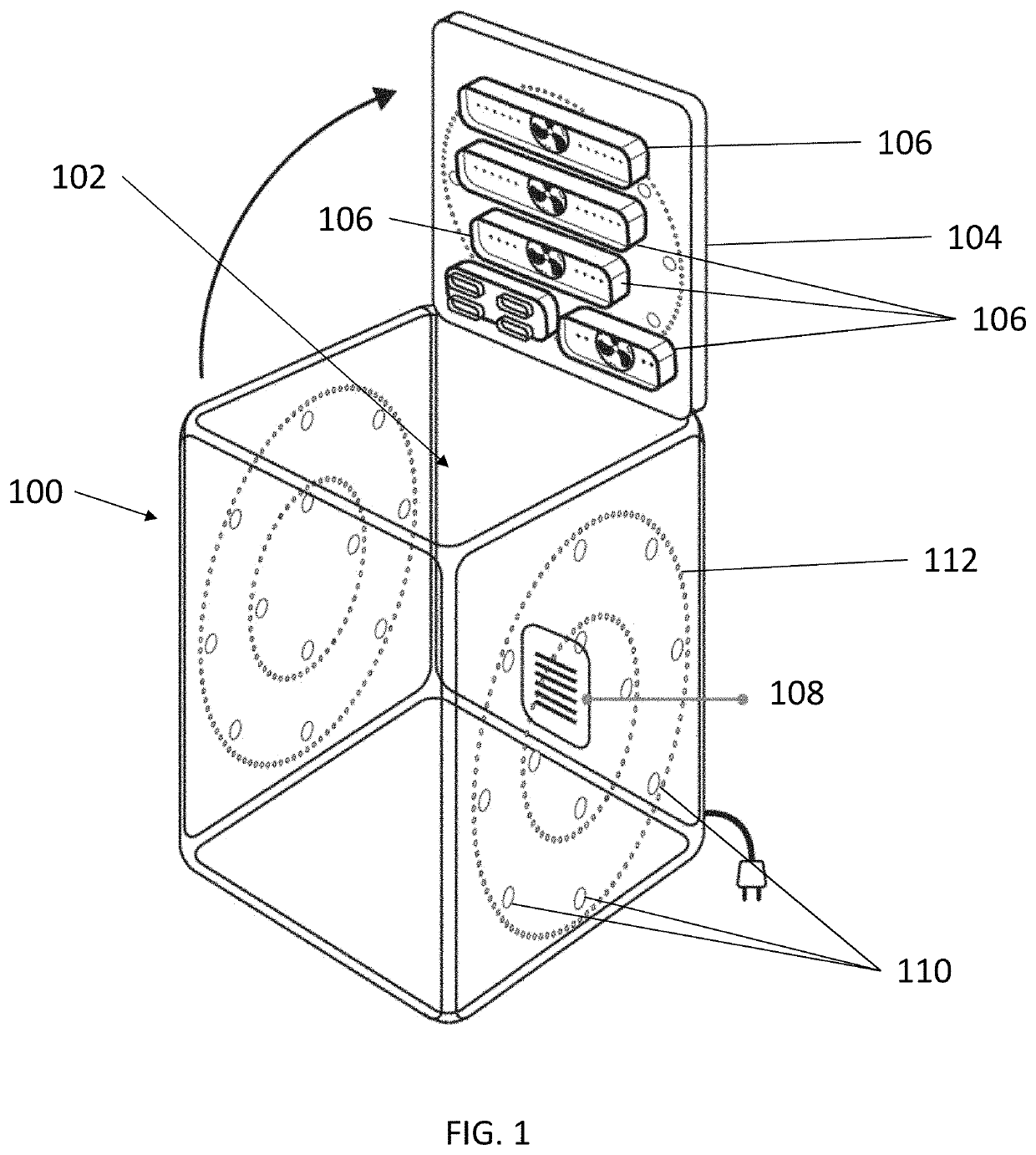

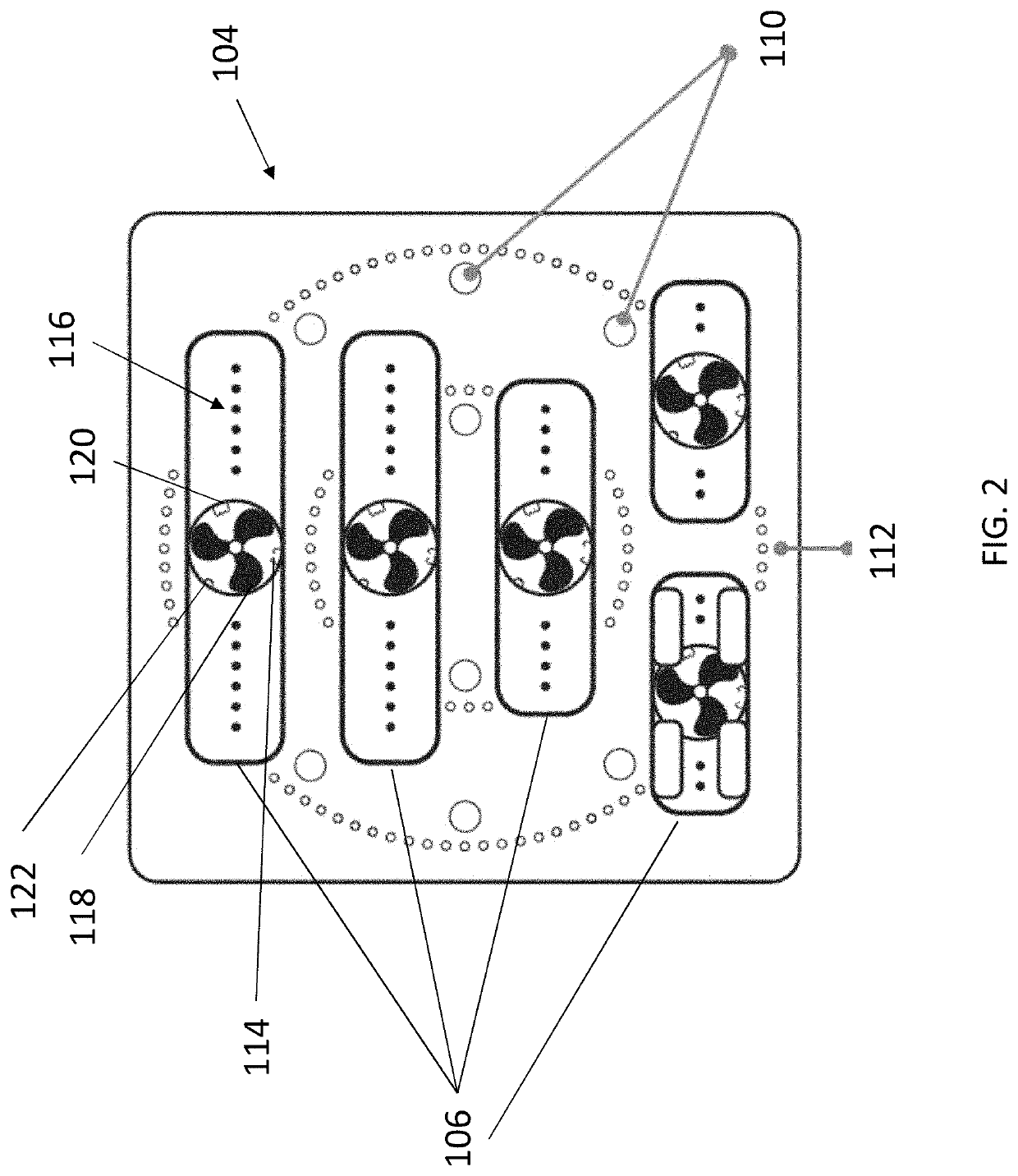

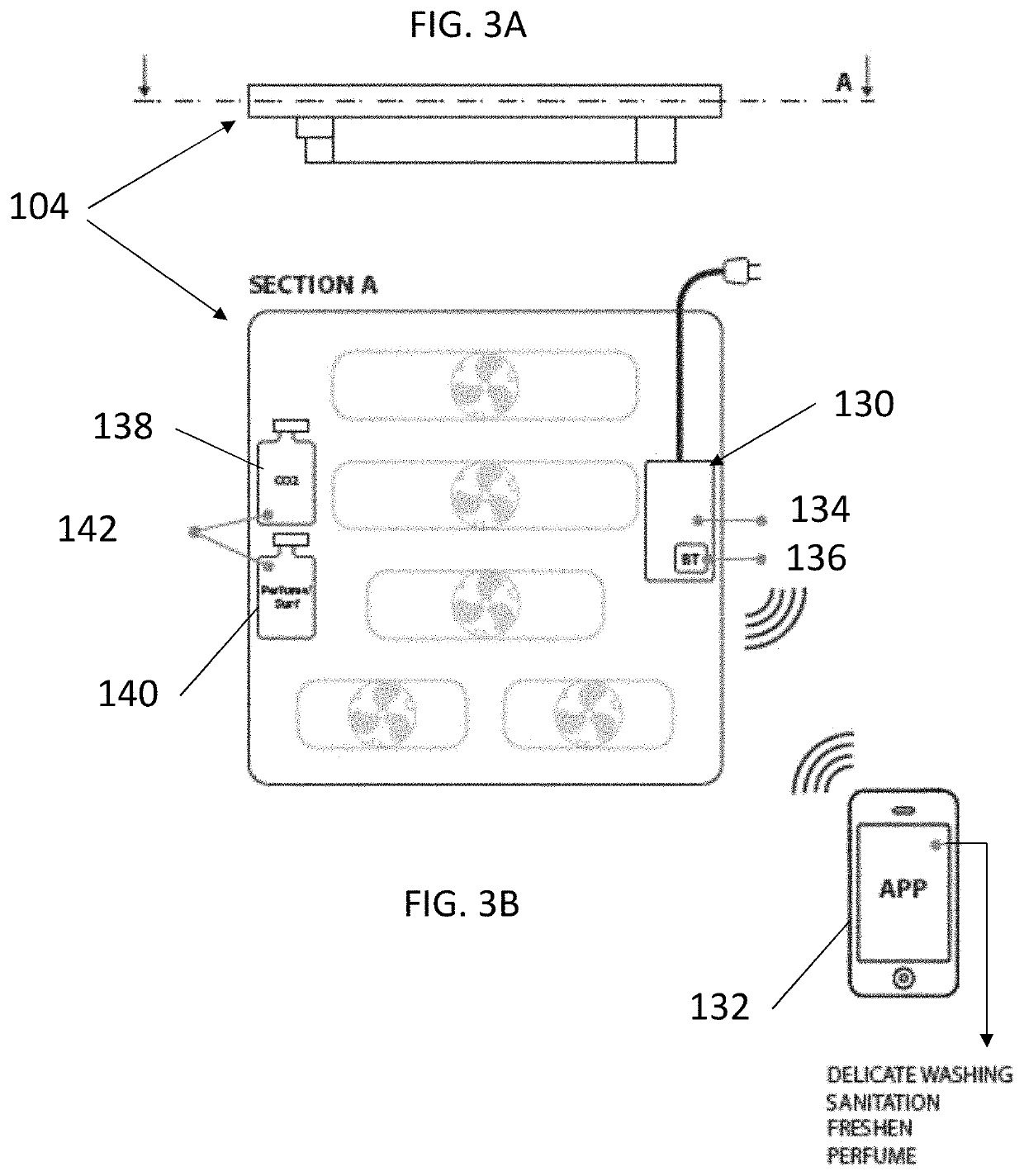

[0032]Laundry apparatuses (e.g. systems and devices) and methods are disclosed herein. The laundry apparatuses described herein can clean one or more garments without the use of water by providing a plurality of “dry” cleaning and sanitation techniques to the garment. In particular the laundry system can be used in arrangements which allow for thorough cleaning of garments without causing damage to electronics and circuit components that may be part of the garments. Although the devices are particularly well suited for cleaning garments with electronics and conductive portions, the devices are applicable to all types of garments. Examples of the cleaning and sanitation techniques that can be provided to the garment by the laundry systems described herein include: carbon dioxide, a surfactant, UV light, ultrasound, ozone, and a perfume.

[0033]In some embodiments ozone can be provided by the cleaning system to the garment. Ozone (O3) is a powerful oxidant that destroys bacteria and can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com