Dynamic sweep angle measurement for fault monitoring of windshield wiper systems

a technology of windshield wipers and sweep angles, which is applied in vehicle maintenance, vehicle cleaning, transportation and packaging, etc., can solve the problem that wws is not typically expected to have any movement or flutter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

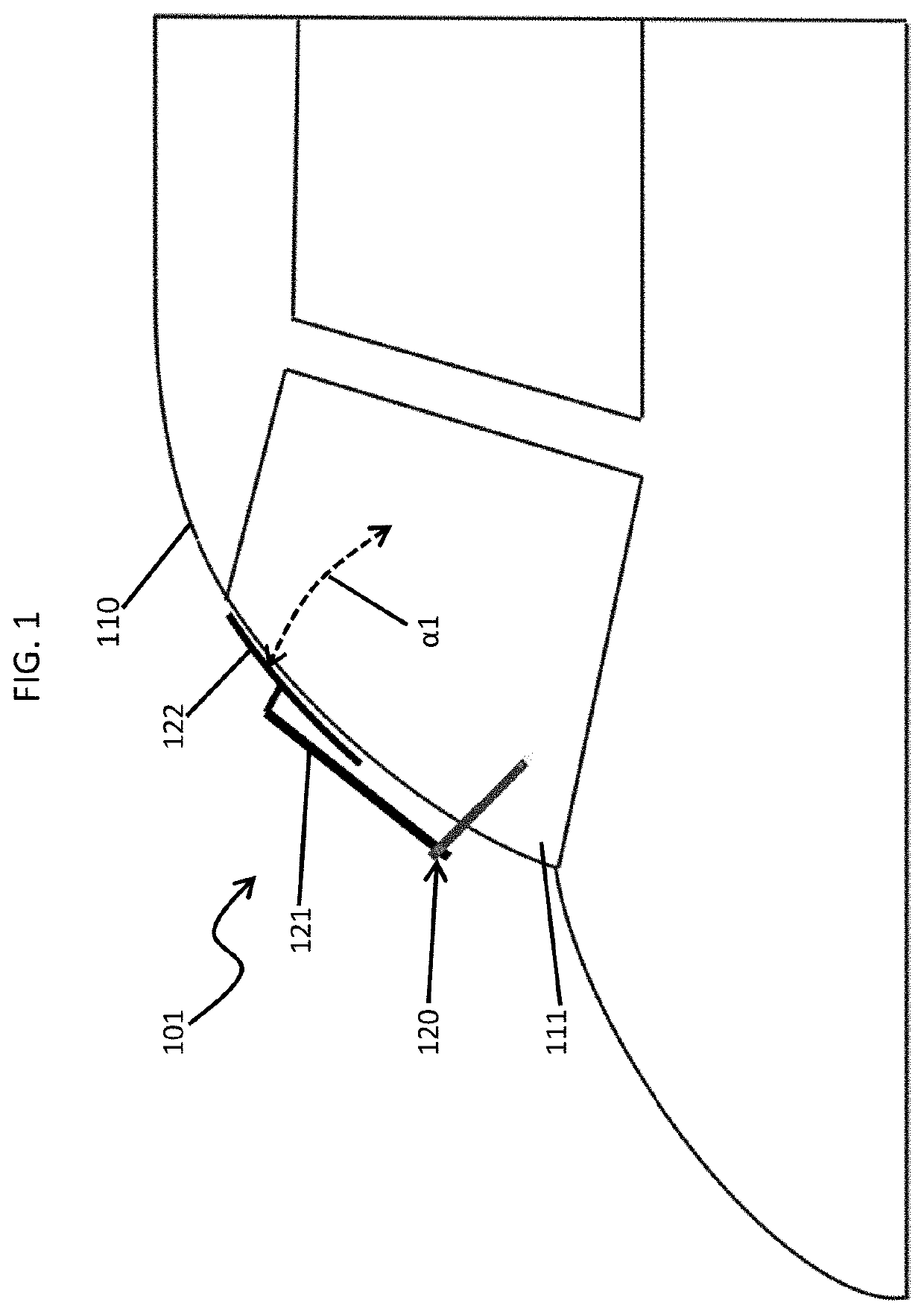

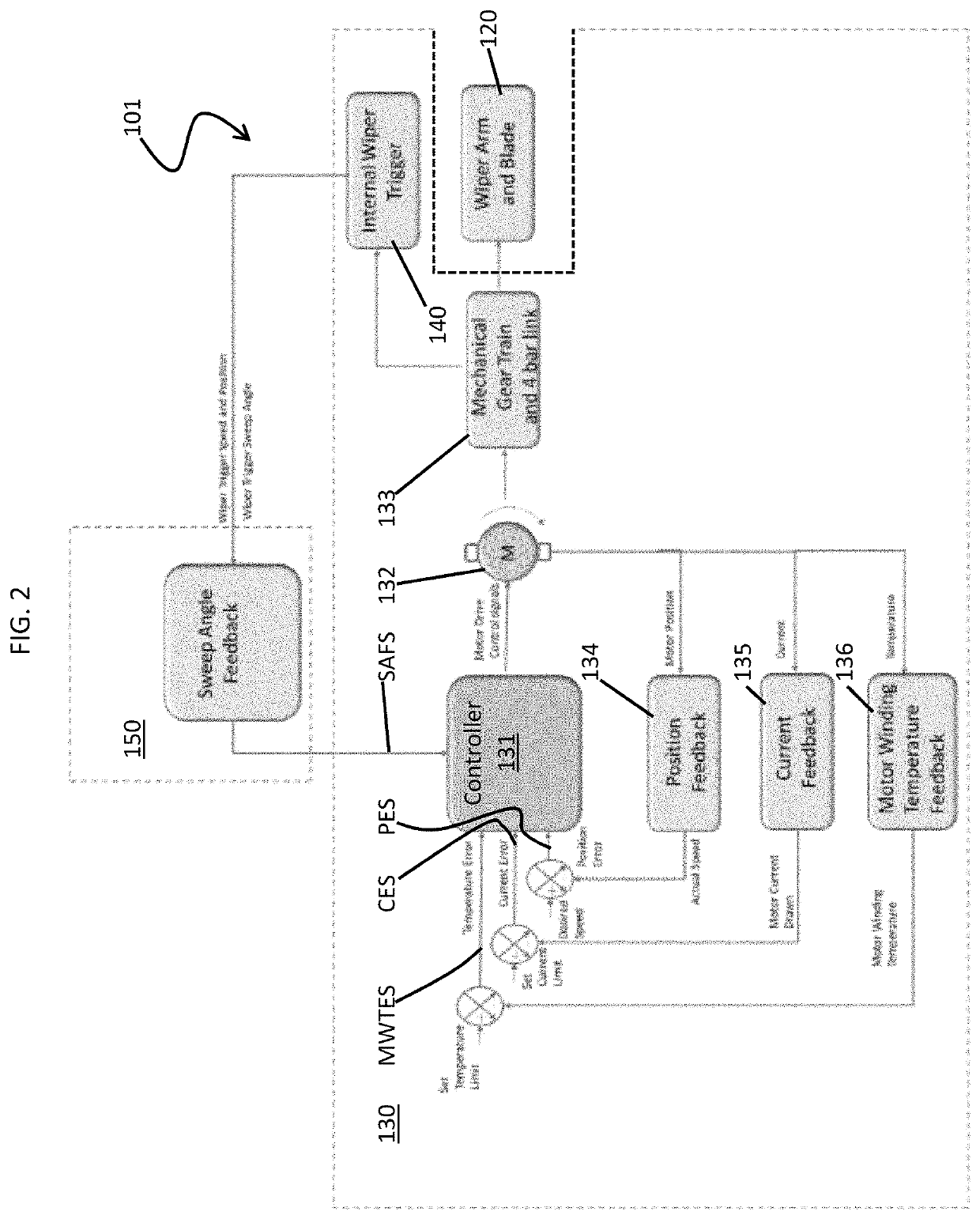

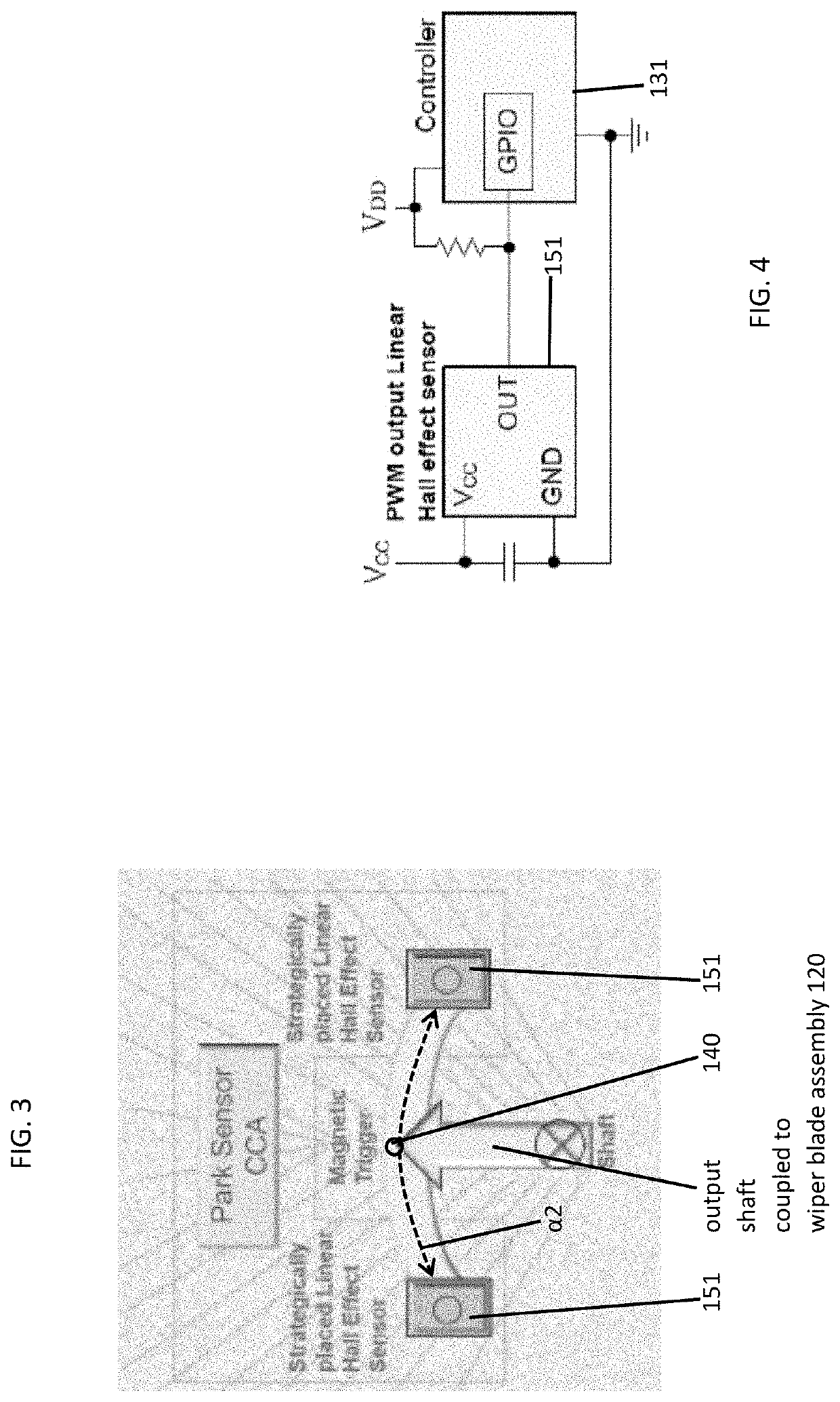

[0034]A conventional WWS can include an intelligent device with a controller or processor that provides a motor commutation sequence and monitors system faults, an internal wiper trigger that detects an end of sweep position of an external wiper blade, a park sensor feedback system with an end of sweep (EoS) sensor that detects the end of sweep position of the WWS by monitoring the internal wiper trigger, Hall sensor feedback to measure a speed of a motor of the WWS, motor current feedback to monitor motor winding currents, motor winding temperature feedback to monitor temperatures of the motor windings, a mechanical gear train and four bar link mechanism and a wiper arm and blade. The mechanical gear train and the four bar link mechanism converts rotary motion of the motor to oscillatory motion and the wiper arm and blade is driven by the oscillatory motion to wipe the windshield.

[0035]Thus, in the conventional WWS, it is seen that Hall sensors are used to detect a speed of the mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com