Shipping pallet sleeve system and methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

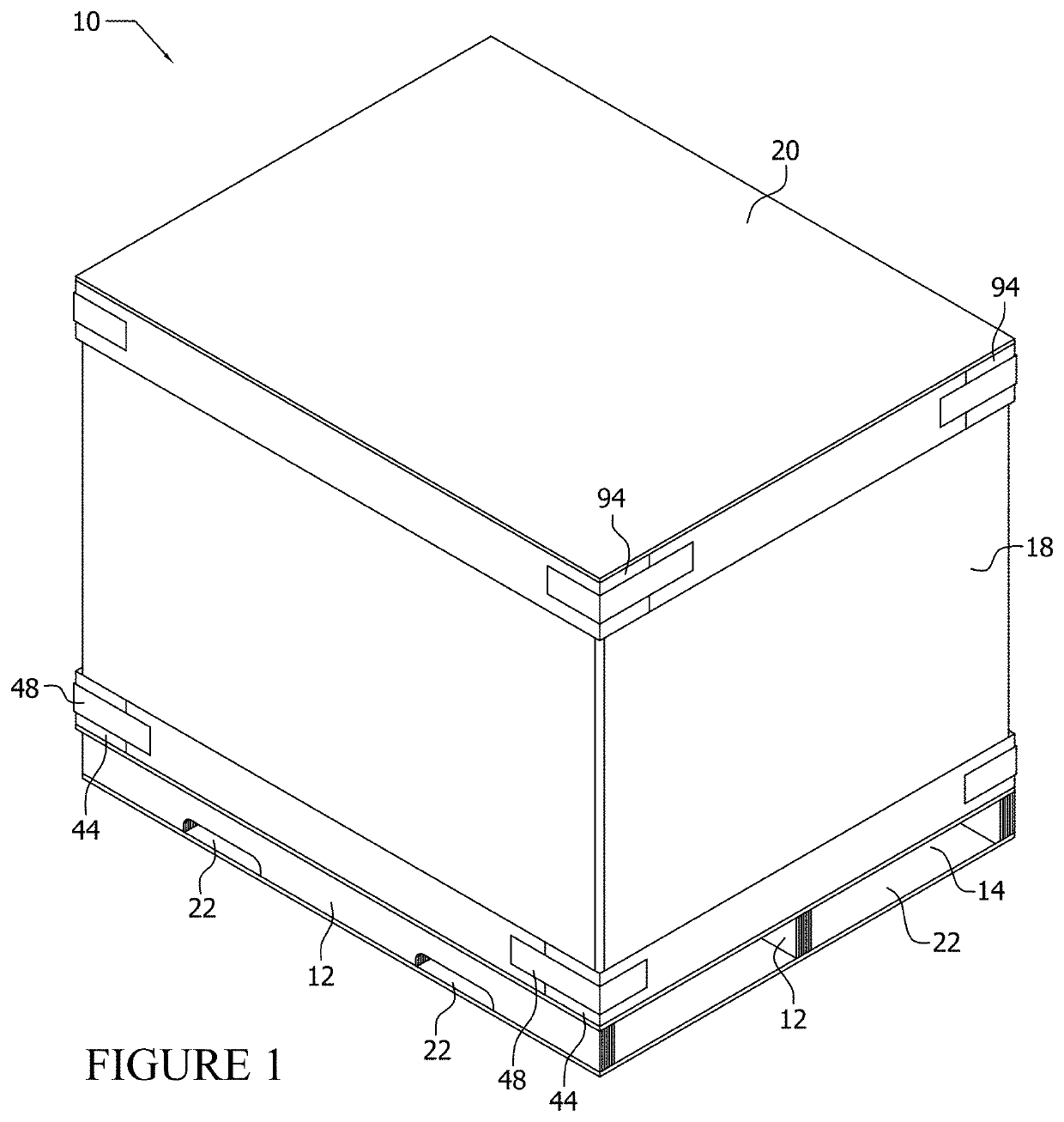

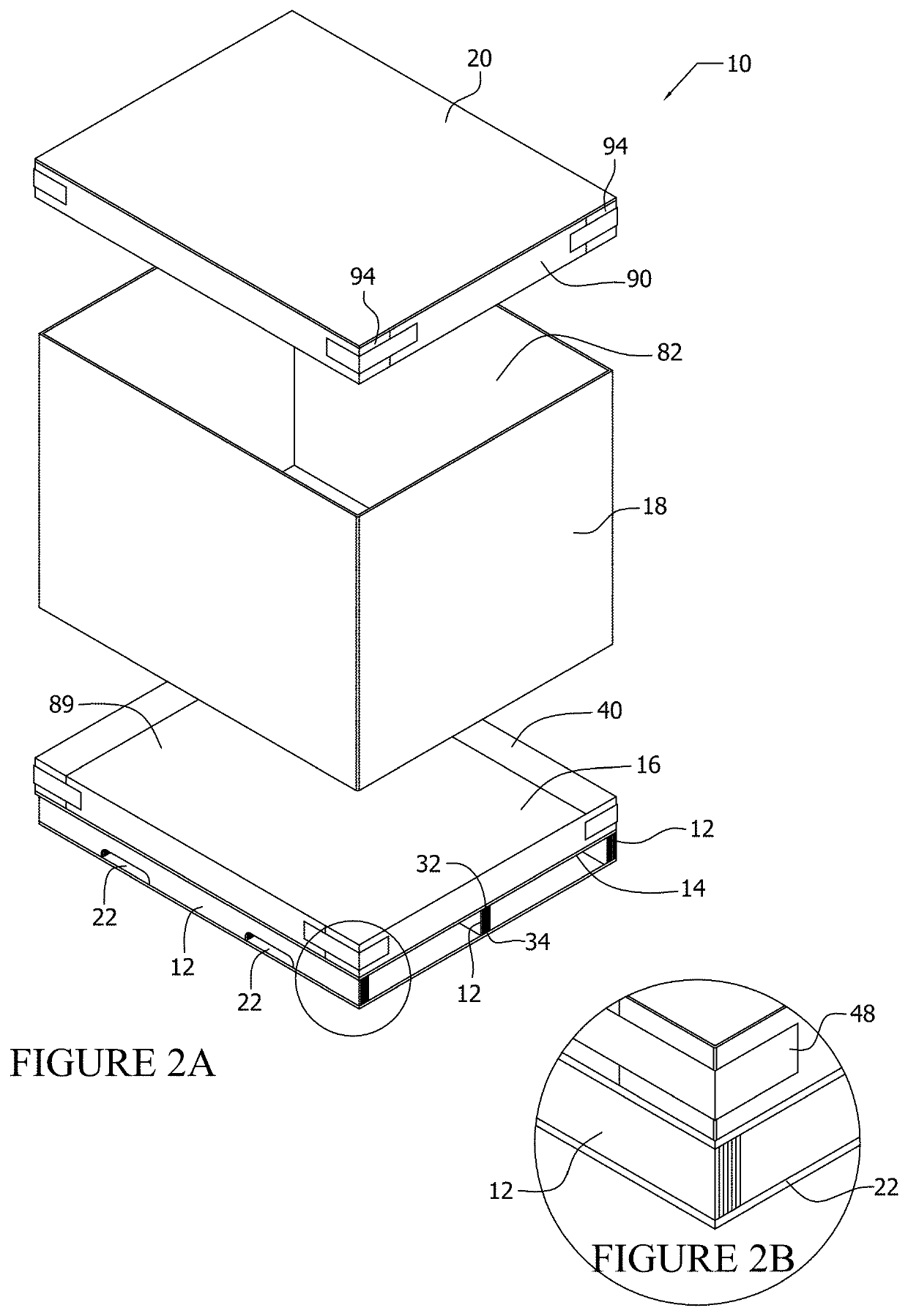

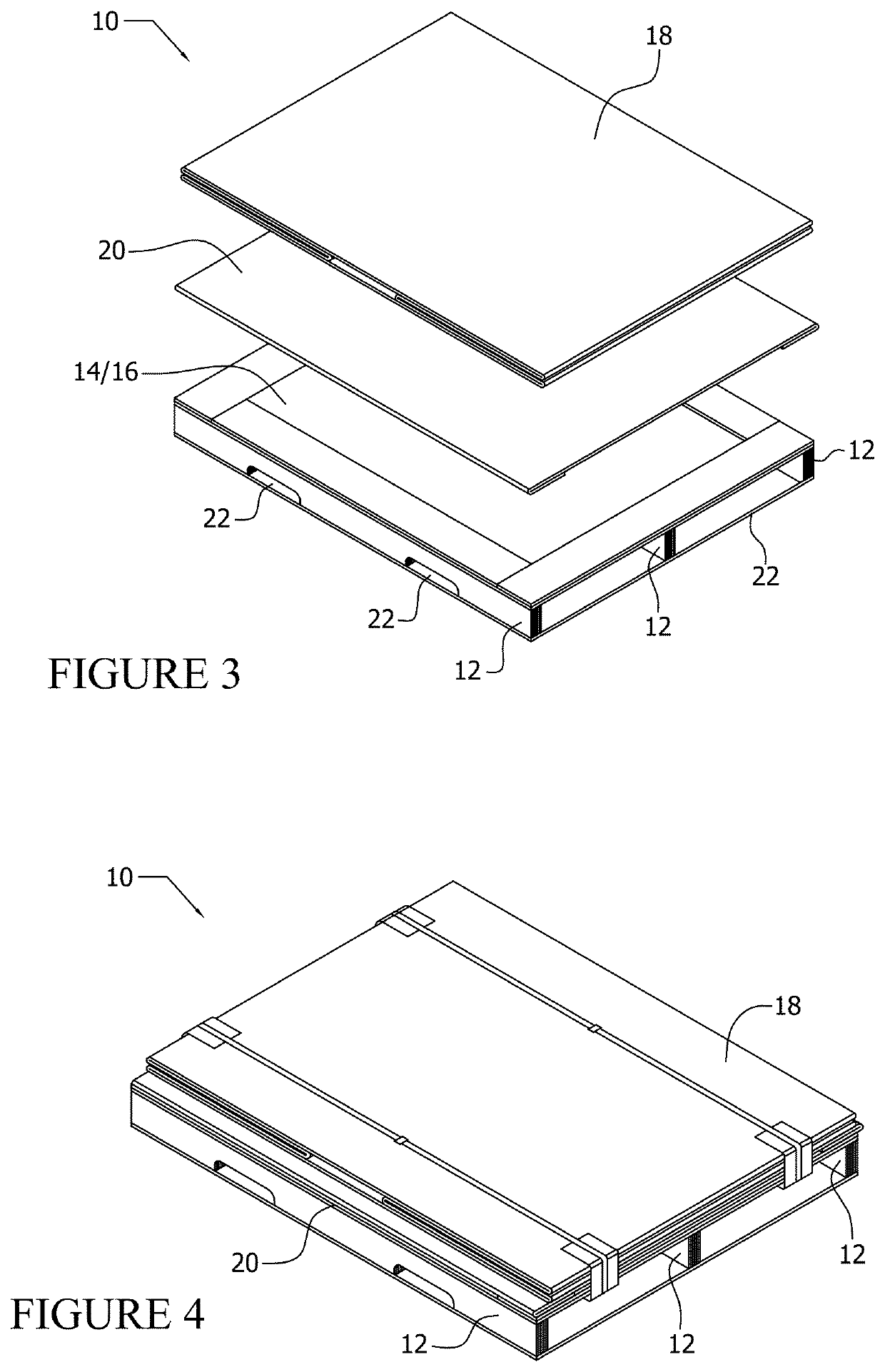

[0026]The Figures generally illustrate exemplary implementations of a sleeve pallet 10 for the containment and shipping of goods that include aspects manufactured in accordance with the present inventions. The particularly illustrated implementations of sleeve pallet 10 has been chosen for ease of explanation and understanding of various aspects of the present inventions. It will be understood that the term shipping pallet shall include other similar products used for shipping cargo such as skids, box pallets, shipping crates, and the like that may use the elements of sleeve pallet 10 or other structurally similar components manufactured in accordance with methods of the present teachings. That said, the illustrated implementations are not meant to limit the scope of coverage but, instead, to assist in understanding the context of the language used in this specification and in the appended claims. Accordingly, the appended claims may encompass variations of sleeve pallet 10 that dif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com