Automated case handling system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

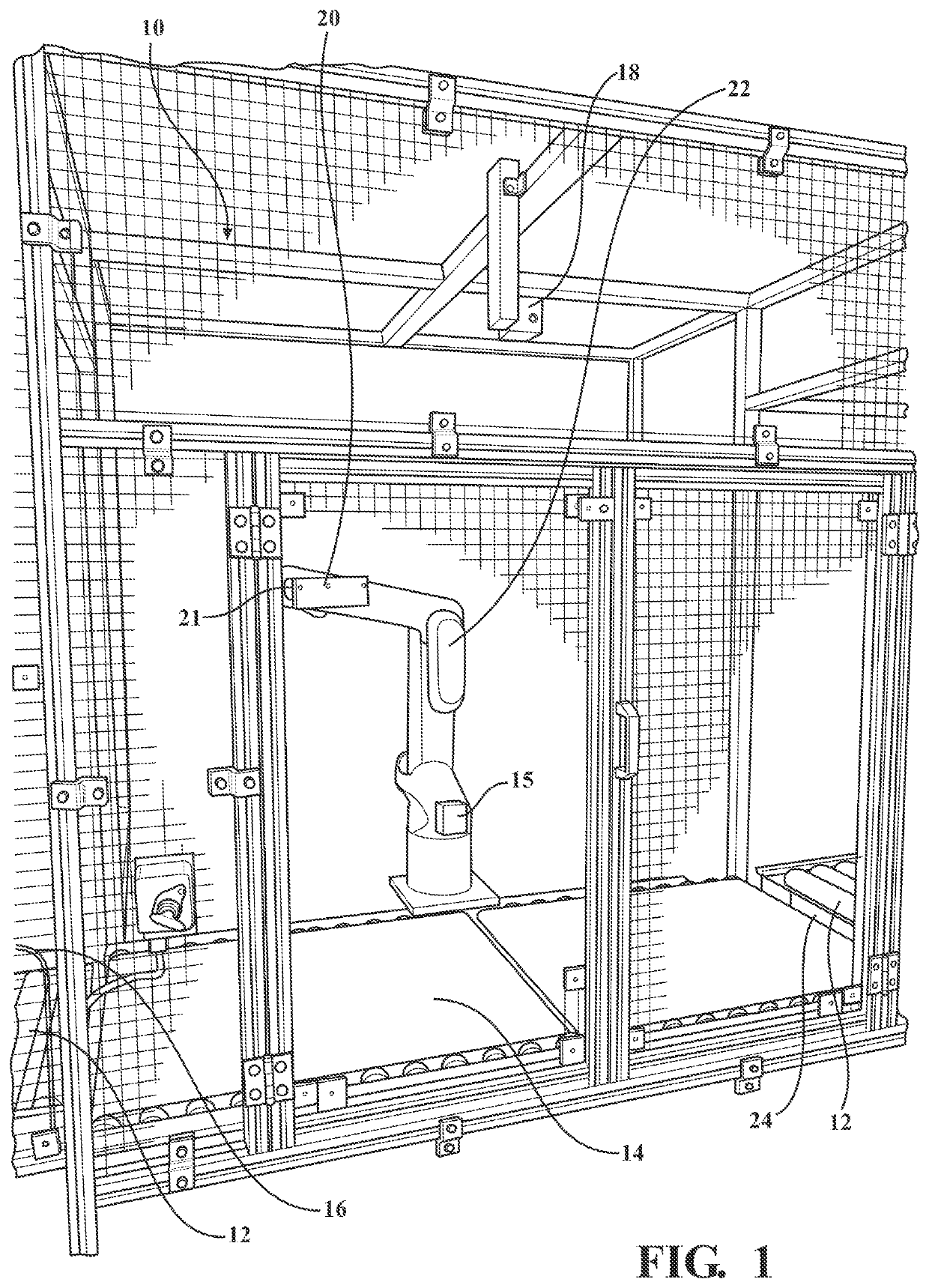

[0016]The automated package or case handling system of the present invention is shown generally at 10 in FIG. 1. The system 10 is mounted along a travel path which is illustrated as a continuous conveyor 12. It should be understood that that the travel path could take different forms other than a conveyor. For example, the path could be a robot moving the cases to the system 10, or a ramp upon which the cases slide to the system 12, etc. The handling system 10 has a system travel path 14 which can be inserted into the main continuous conveyor system 12. The travel path is shown as a conveyor, but again, it could be a robot holding the case or a flat surface upon which the case rests. The system also includes a secondary path 16 upon which cases that are not acceptable are conveyed.

[0017]The system 10 of the present invention rapidly handles cases of random size. For example, the system 10 can check whether the case has been properly sealed on the top and bottom, can apply labels to ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap