Press formed component and method for manufacturing same

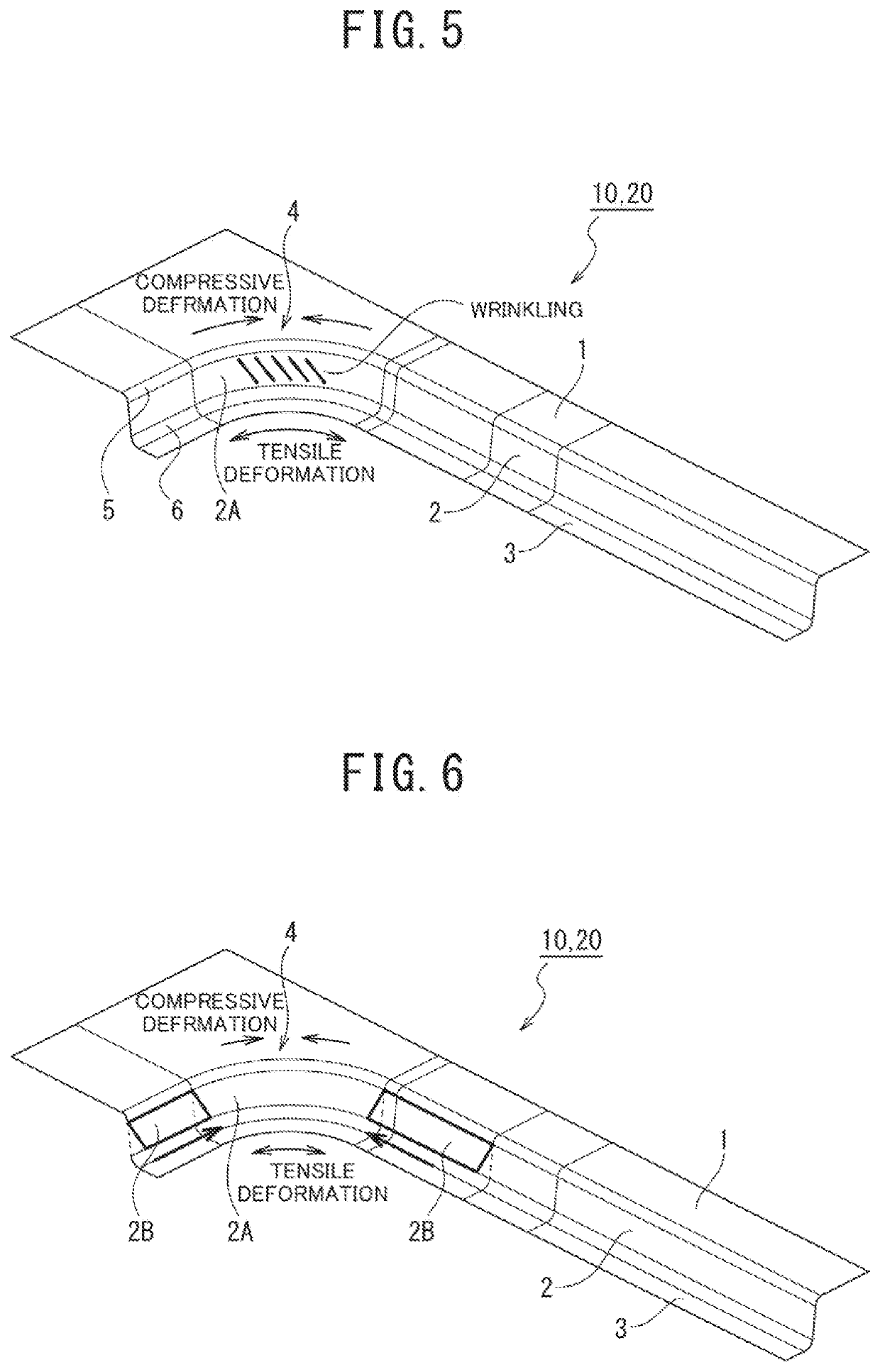

a technology of components and components, applied in metal-working feeding devices, manufacturing tools, transportation and packaging, etc., can solve problems such as wrinkles on the vertical wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

[0081]An Example based on the present embodiment will be described.

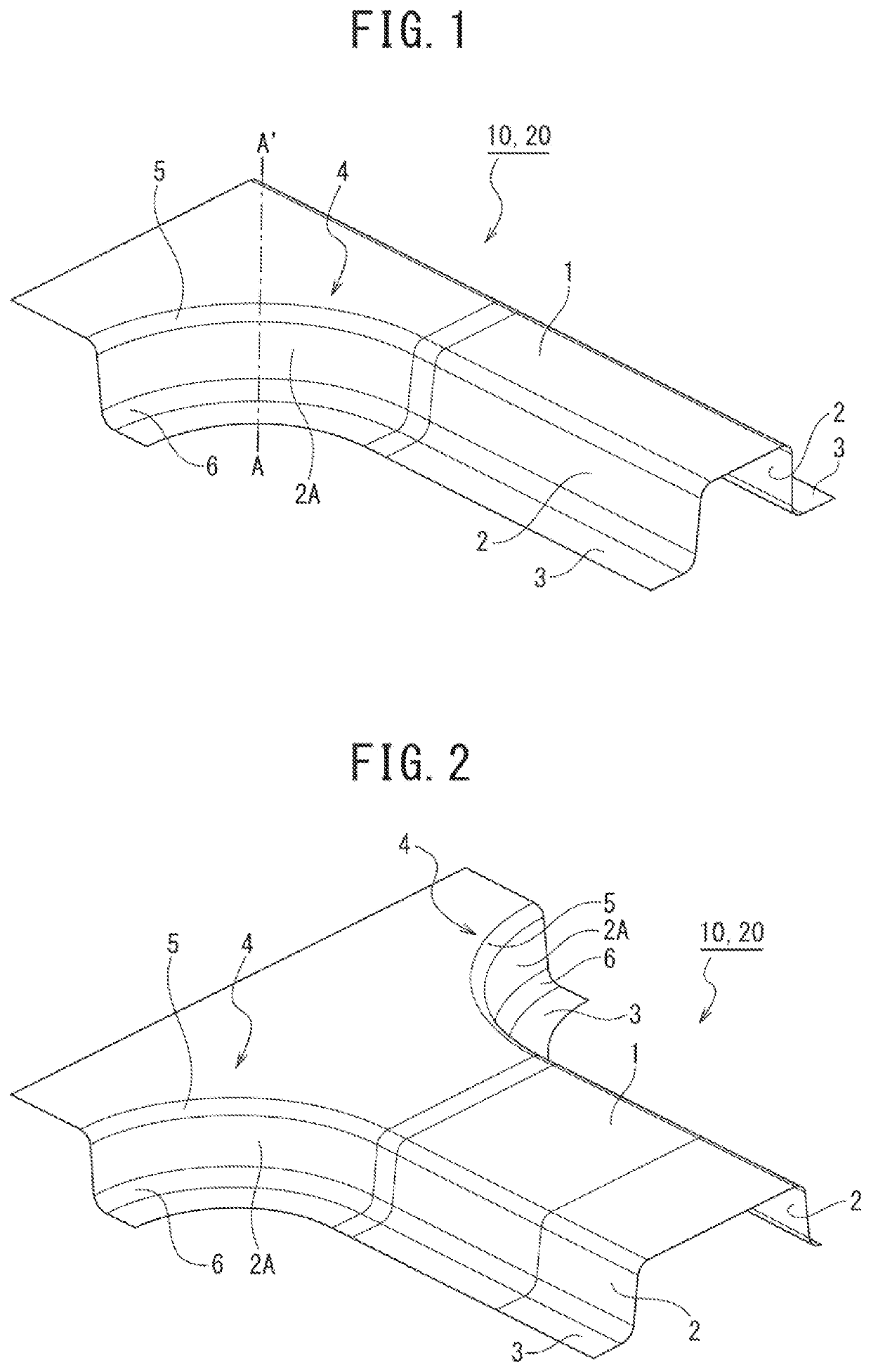

[0082]A 980 MPa-class cold-rolled steel sheet (sheet thickness: 1.4 mm) was used as the material metal sheet, and a component shape having a T-shape as illustrated in FIG. 12 was set as the curve-containing component shape 10. The component shape includes the curved portion 4 on each widthwise side of the top sheet portion 1 on the left side on the paper in FIG. 12.

[0083]The following conditions were adopted as forming analysis conditions for the geometric shape of the above component.

[0084]

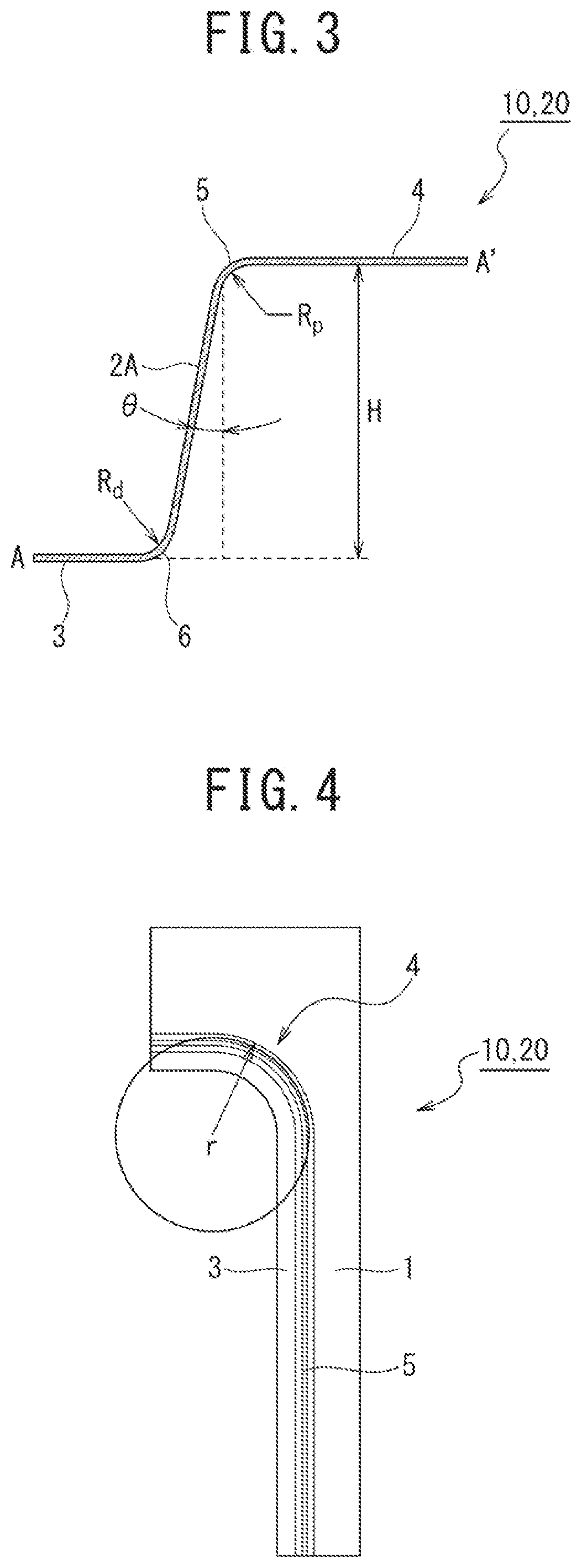

[0085]Height H of vertical wall portion: 60 mm

[0086]Inclination angle θ: 2 deg, 7 deg, and 12 deg

[0087]Length f at an outer edge of the flange portion 3 in the curved portion 4: 30 mm

[0088]Punch shoulder R (curvature radius Rp at boundary portion 5): 10 mm

[0089]Die shoulder R (curvature radius Rd at boundary portion 6): 8 mm, 12 mm, and 16 mm

[0090]Curved portion R (curvature radius r of curved portion): 100 mm, 150 mm, and 200 mm

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| inclination angle | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com