Linkage mechanism acting in opposite directions synchronously

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

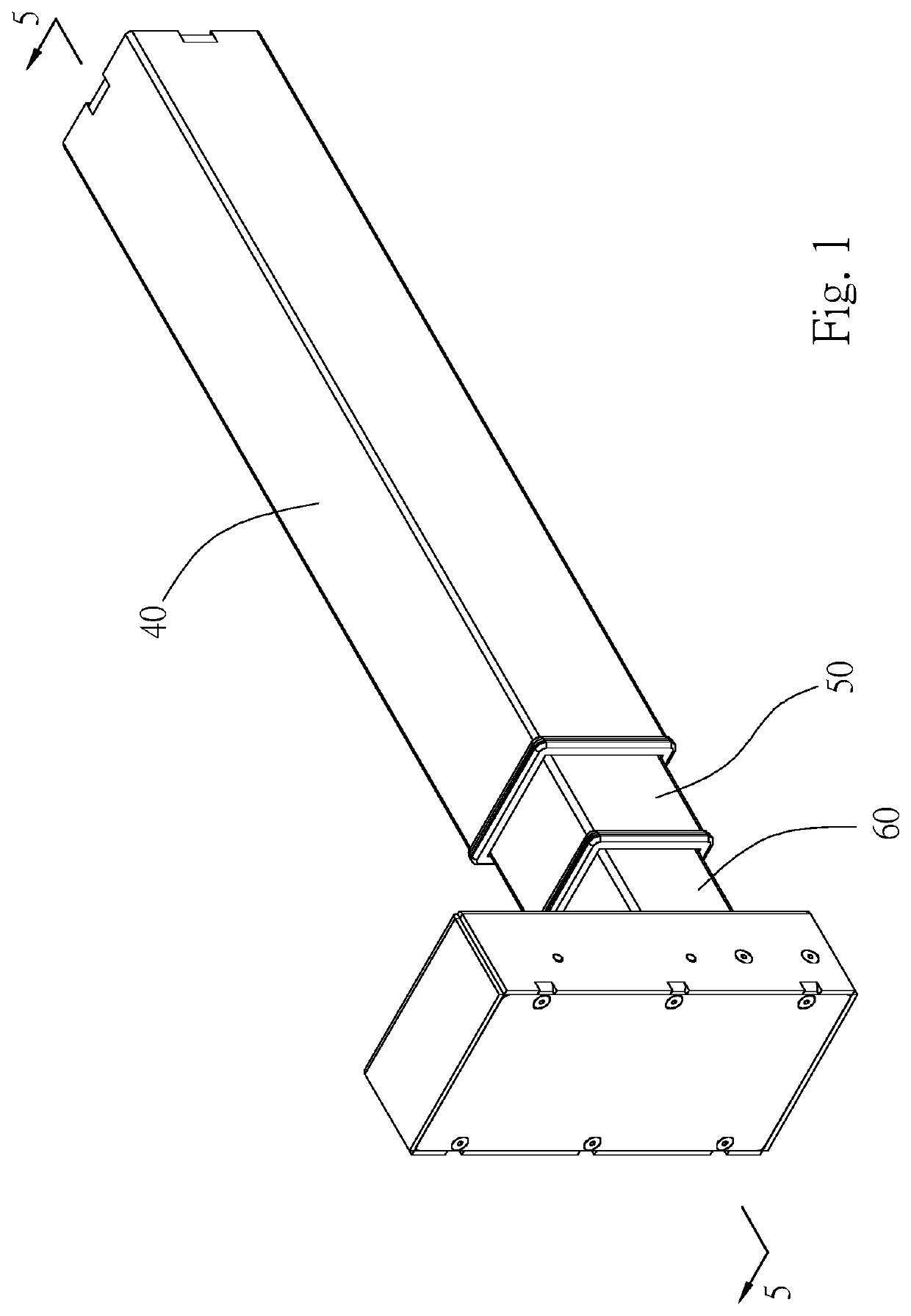

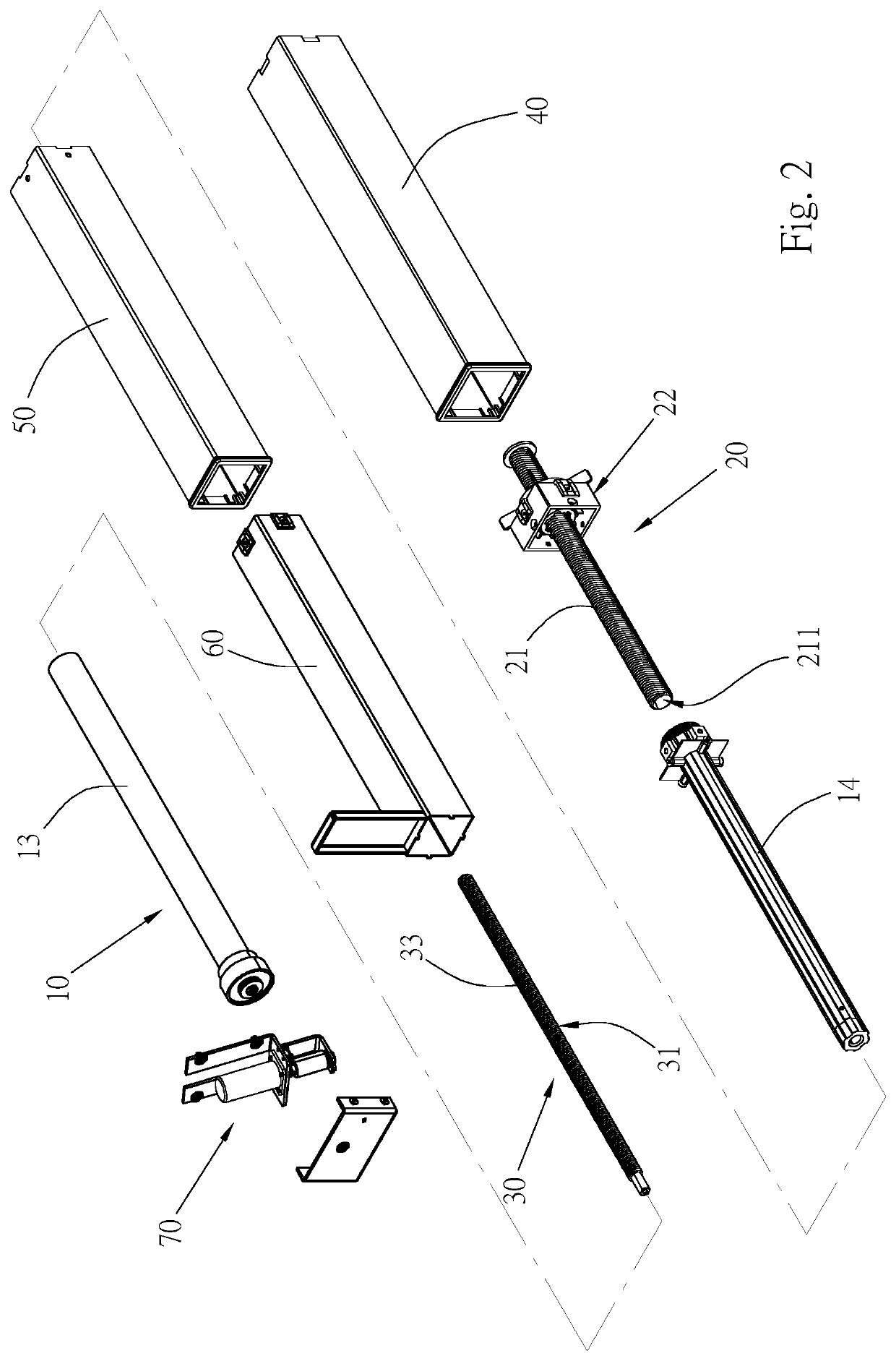

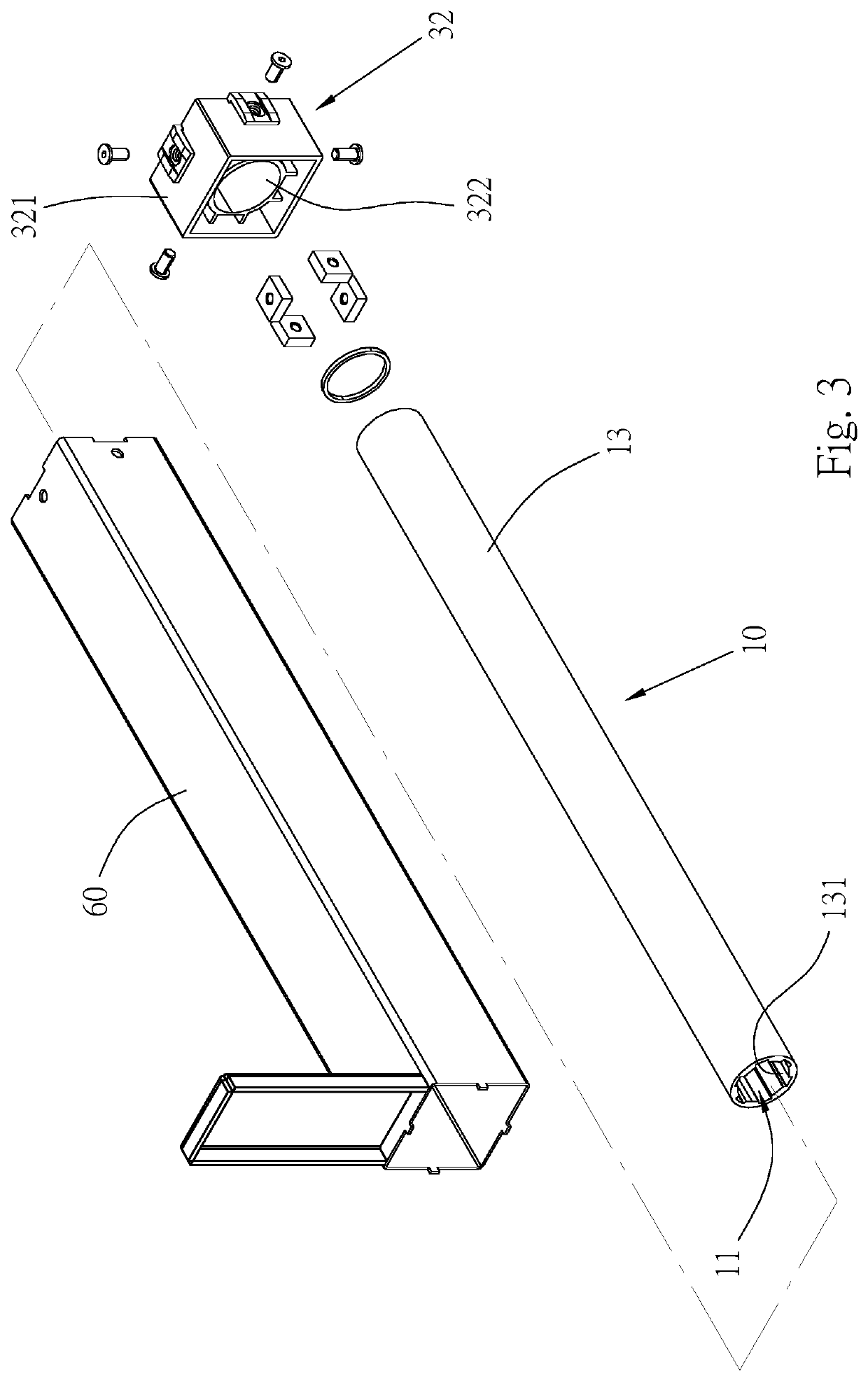

[0023]First of all, please refer to FIGS. 1 to 8. A linkage mechanism acting in opposite directions synchronously provided in a first embodiment of the invention comprises a driving part 10, a first actuating part 20, a second actuating part 30, a first sleeve column 40, a second sleeve column 50, and a third sleeve column 60.

[0024]The driving part 10 has an internal space 11 for accommodating the first actuating part 20 and the second actuating part 30 partially or entirely. When being driven by an external power source 70, the driving part 10 is capable of driving the first actuating part 20 and the second actuating part 30 to displace relatively close to each other in opposite directions or away from each other in opposite directions. Specifically, the driving part 10 has a rotating member 12, an interior of the rotating member 12 forms the internal space 11, when the rotating member 12 is driven by the power source 70 to rotate, the first actuating part 20 and the second actuati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com