Automatic overhead gantry for narrow slit rolls handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

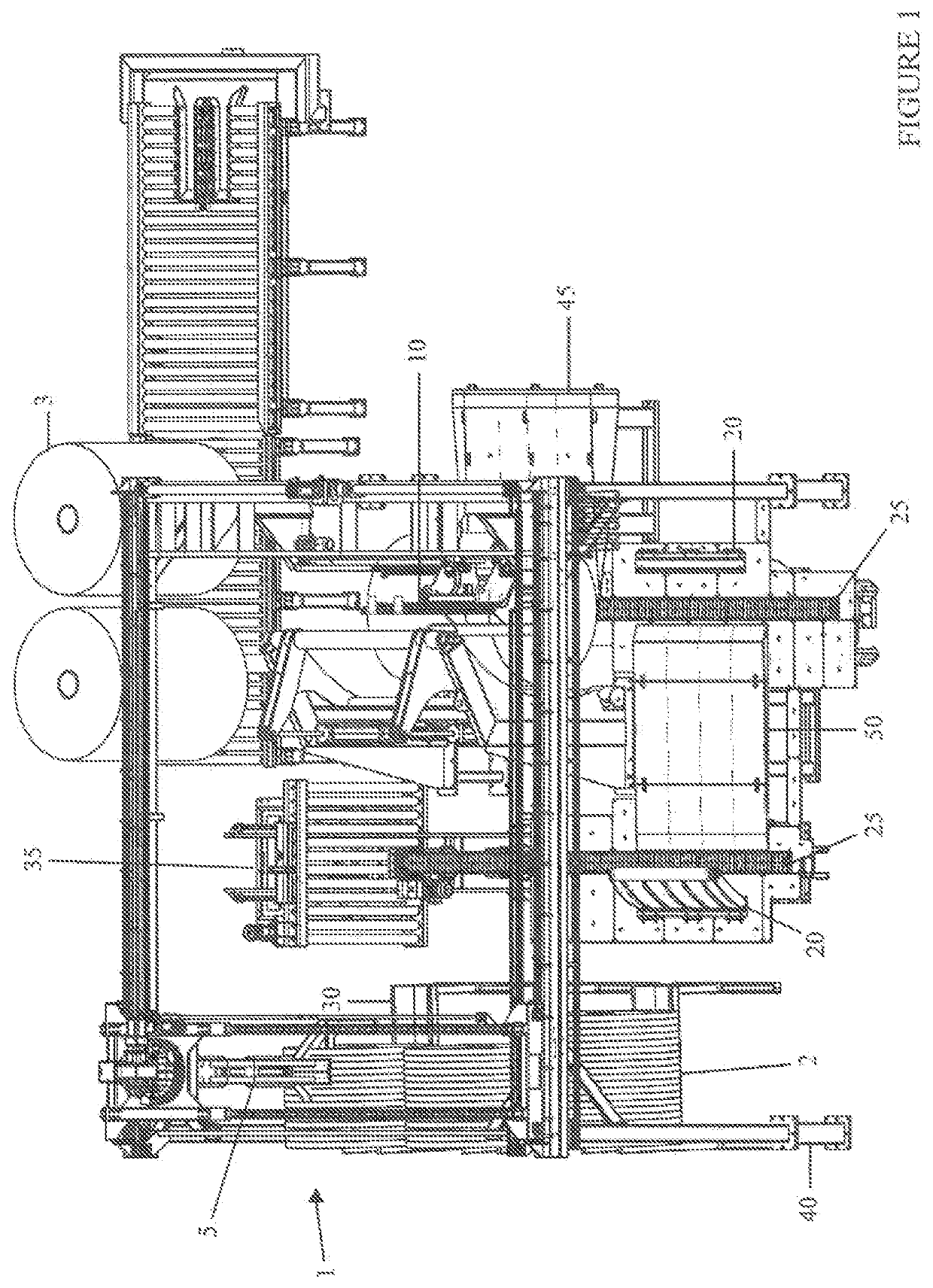

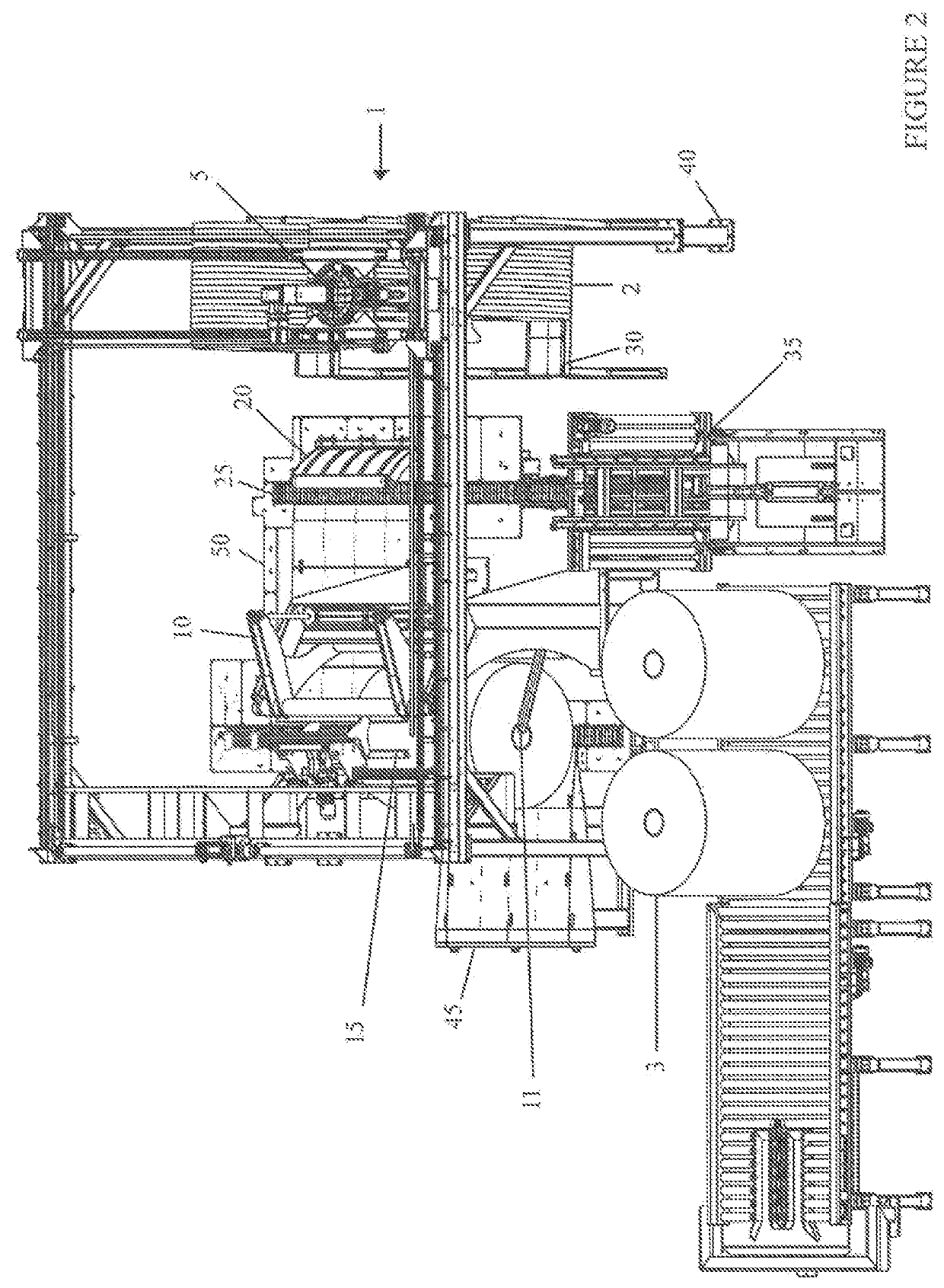

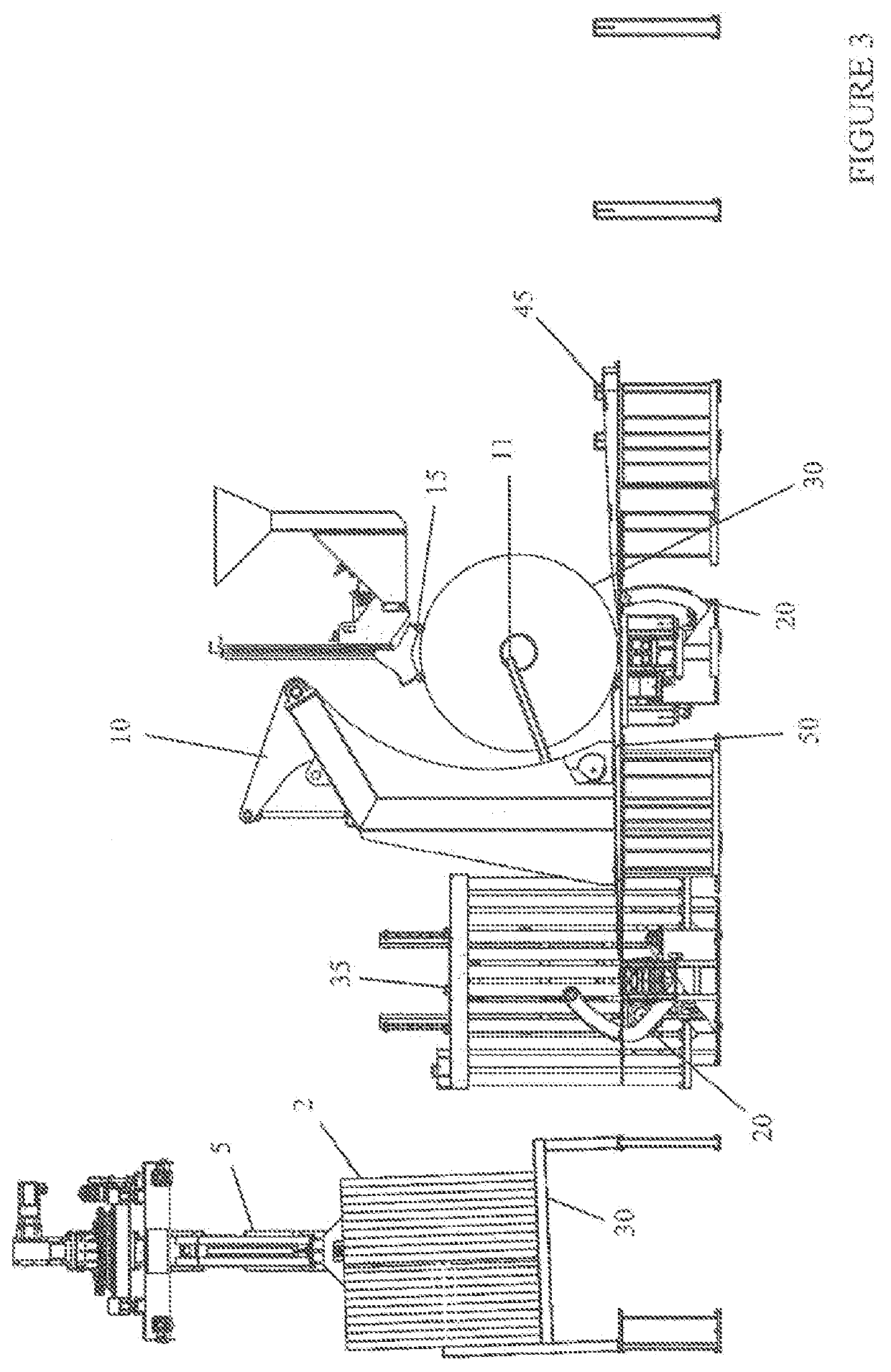

[0044]Referring now to FIGS. 1-17, a narrow-slit handler 1 is shown. The narrow-slit handler 1 comprises an overhead gantry 5, a cushioner 10 with stabilizer arms 11, hold-down 15, conveyors 25, kickers 20, narrow-slit storage 30, and upender 35.

[0045]A roll 3, which has been previously cut into slits of desired widths (narrow-slits 2), enters the narrow-slit handler at ramp 45. The cushioner 10 extends to meet roll 3 with a cushion 12 and at least two stabilizer arms 11. The cushioner 10, using the cushion 12 and stabilizer arms 1, guides roll 3 down ramp 45 and onto conveyor 25. Hold-down 15 centers itself on roll 3 and lowers hold-down arms 16 to make contact with roll 3 and hold the narrow-slits in position to prevent toppling. Overhead gantry 5 positions itself to the side of roll 3, selecting the desired number of narrow-slits 2, clamping the narrow-slits 2 into place and transports the narrow-slits to at least one narrow-slit storage 30 (FIG. 31). Narrow-slit storage 30 is sl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap