Fixing device for quickly fastening and releasing a mechanical part that bears on a support base

a technology of fixing device and mechanical part, which is applied in the direction of couplings, rod connections, ropes and cables for vehicles/pulleys, etc., can solve the problems of causing the head of the screw to rotate, and the rotation of the bayonet mechanism can be guaranteed. , to achieve the effect of quick and reliabl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

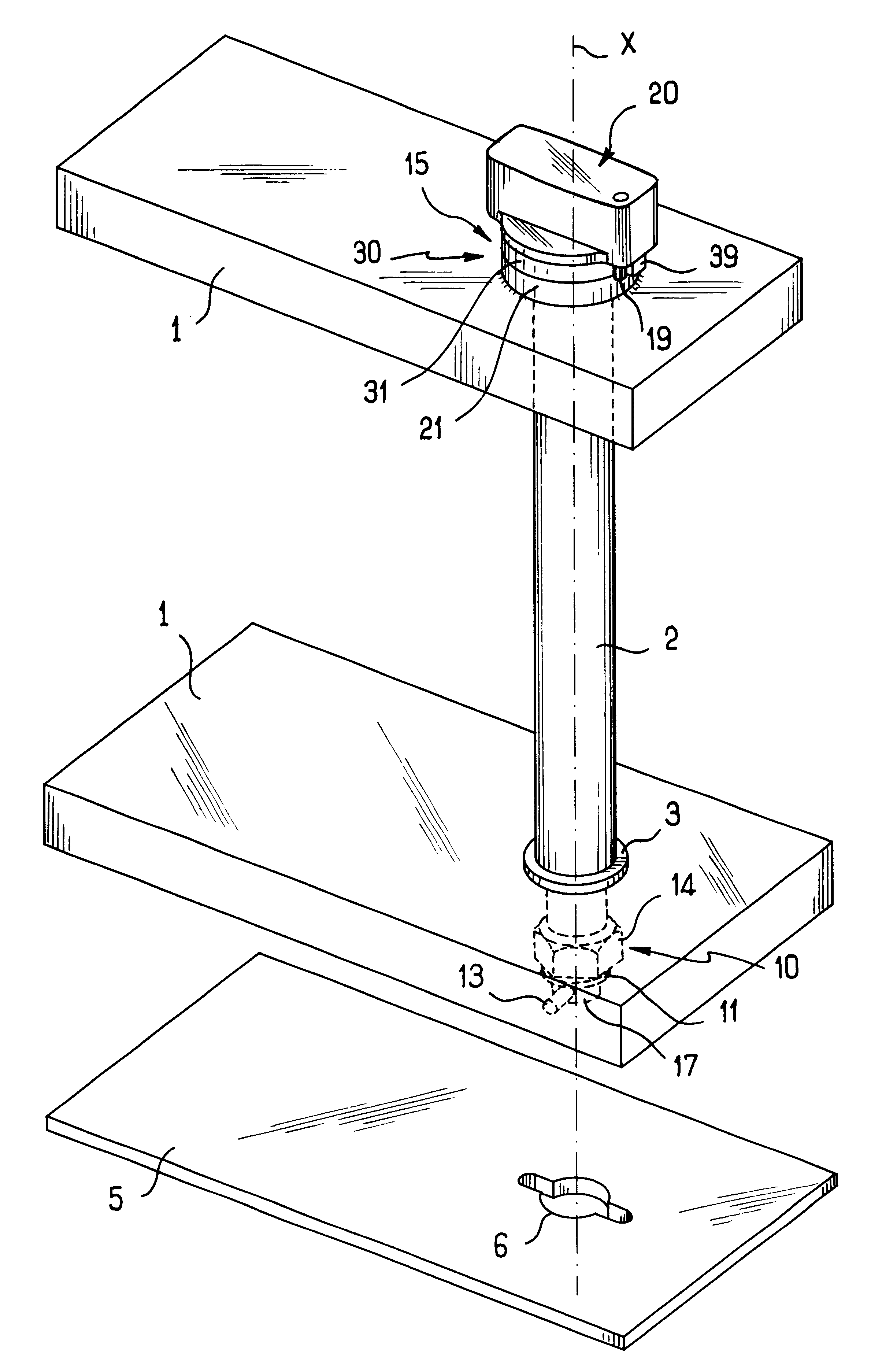

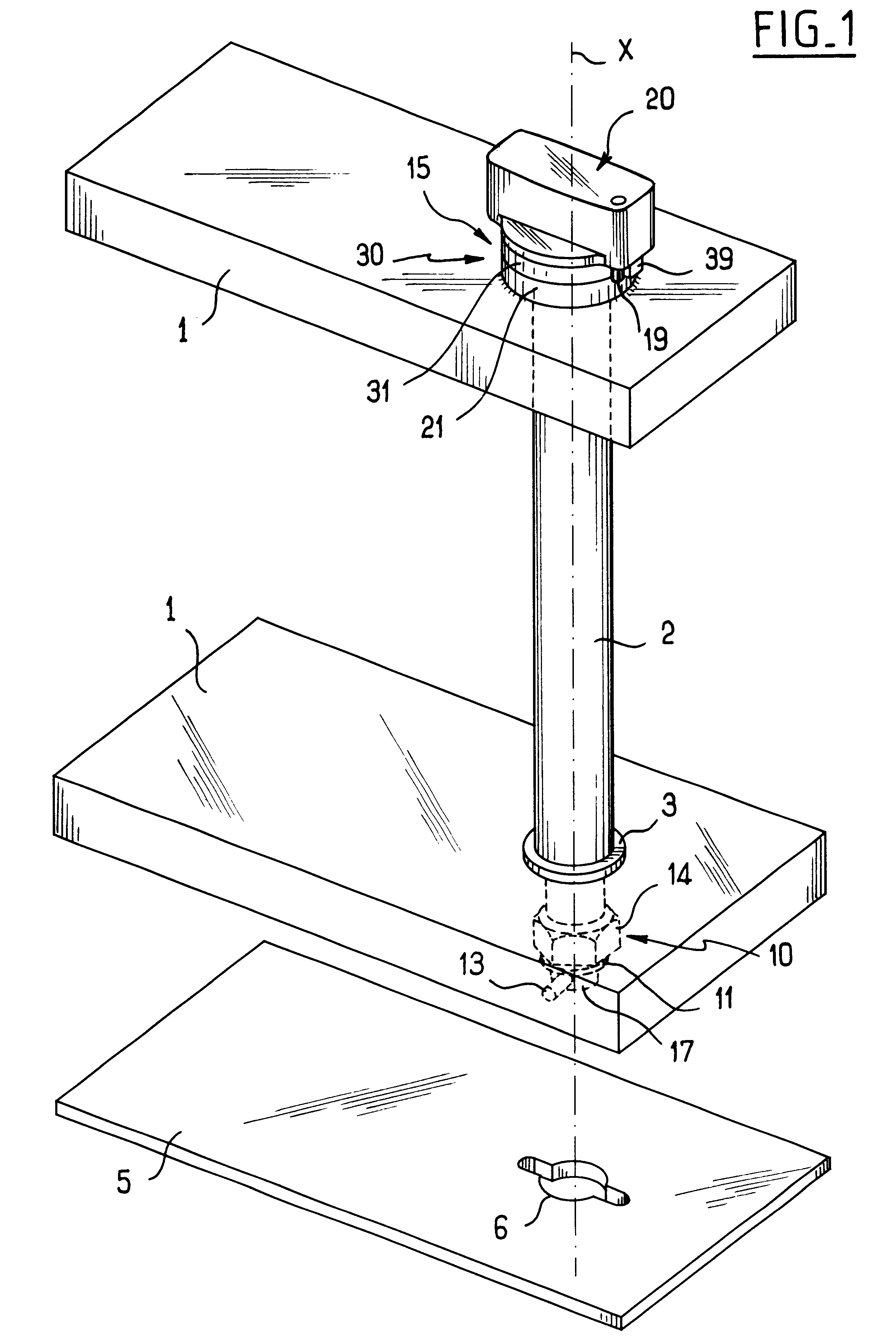

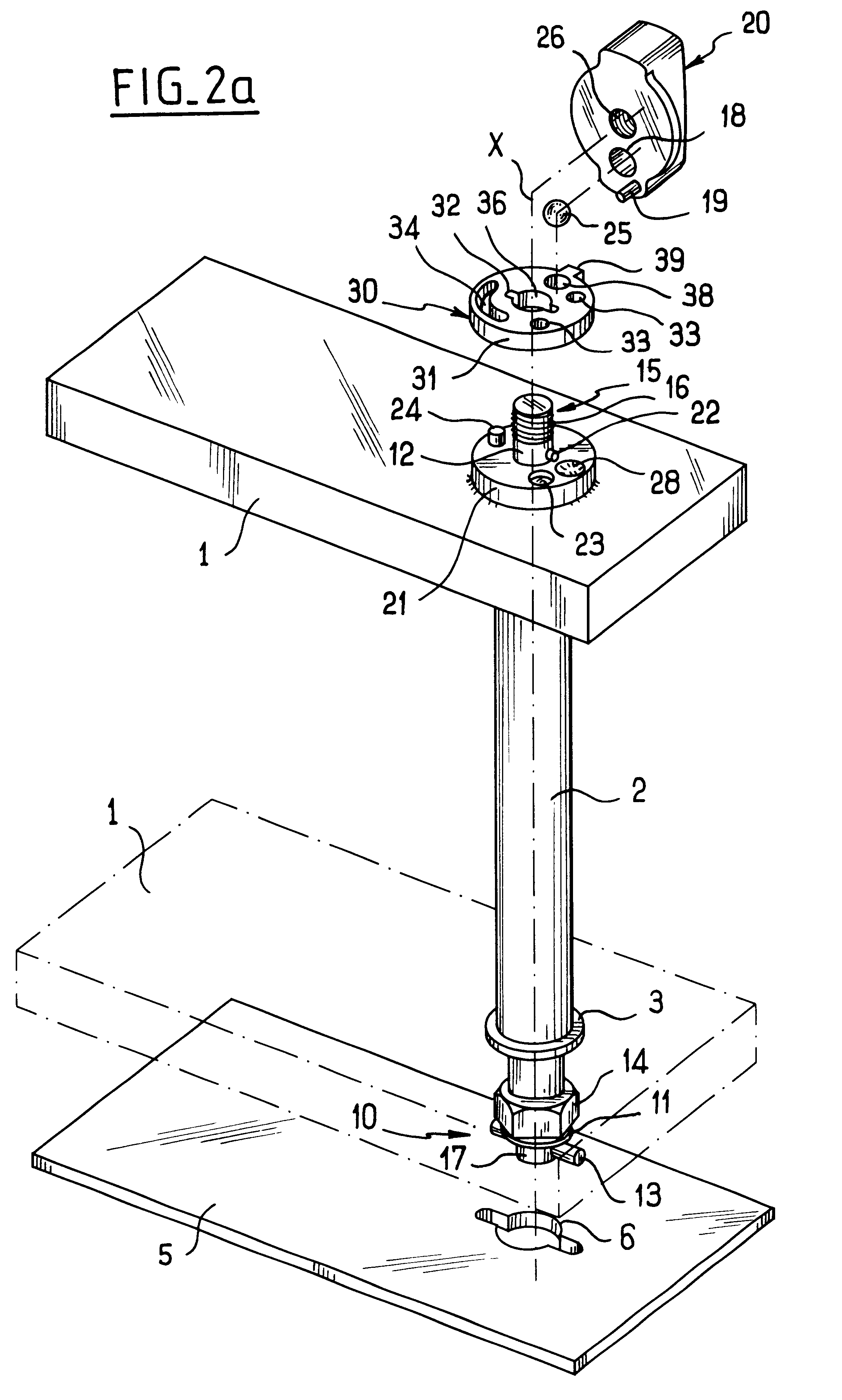

the invention is described below with reference to FIGS. 1 to 2c.

The mechanical part to be fixed is a piece of tooling, in this case constituted by two superposed bars 1, e.g. forming a set of two curved guide bars of the kind used in packaging installations, in particular installations for filling or stoppering receptacles, so as to keep the receptacles traveling around an associated star wheel or cylinder. In this case, the bars 1 are spaced apart by a hollow link tube 2 along which there pass various members used for fixing this tooling to a support base referenced 5.

The fixing device comprises firstly a latching mechanism 10 with some of the components thereof being visible in FIG. 1. The bottom bar 1 is held between a nut 14 and a bearing collar 3 that is rigidly secured to the hollow tube 2. Beyond the nut 14, there can be seen the free end 17 of a central rod that passes along the inside of the hollow tube 2, the rod having projecting portions that are implemented in this cas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com