Side-emission type semiconductor light-emitting device and manufacturing method thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

BEST FORM FOR PRACTICING THE INVENTION

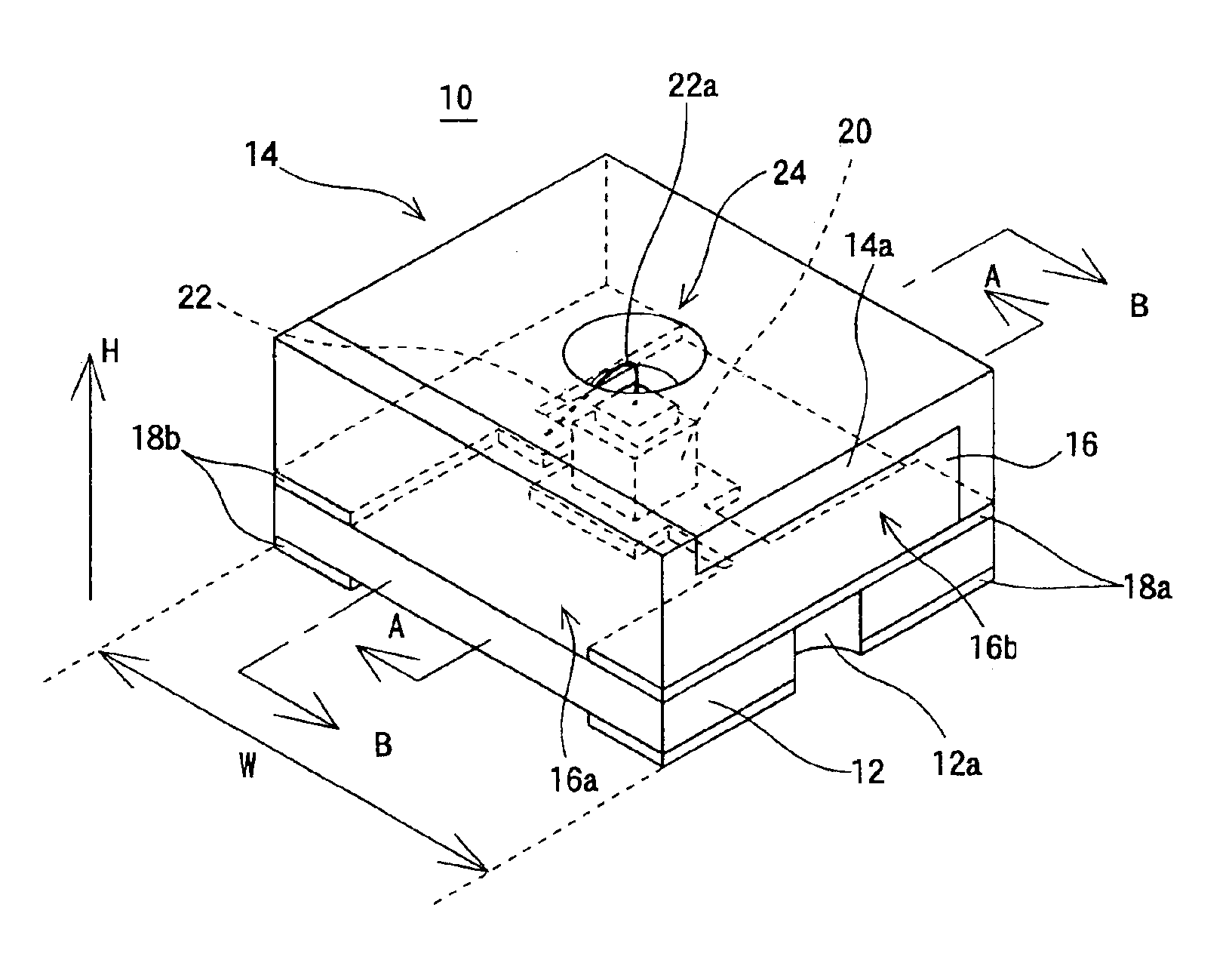

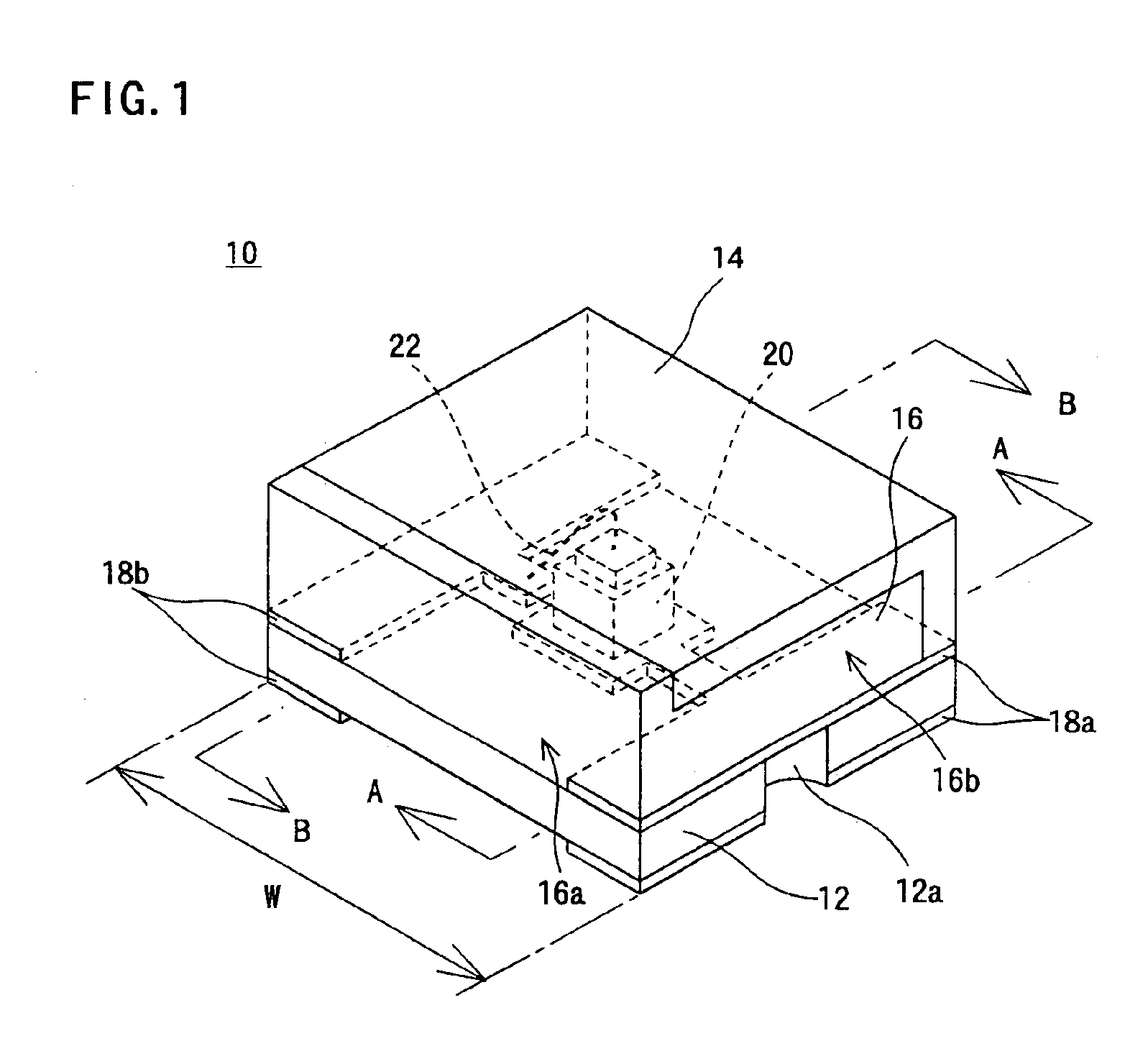

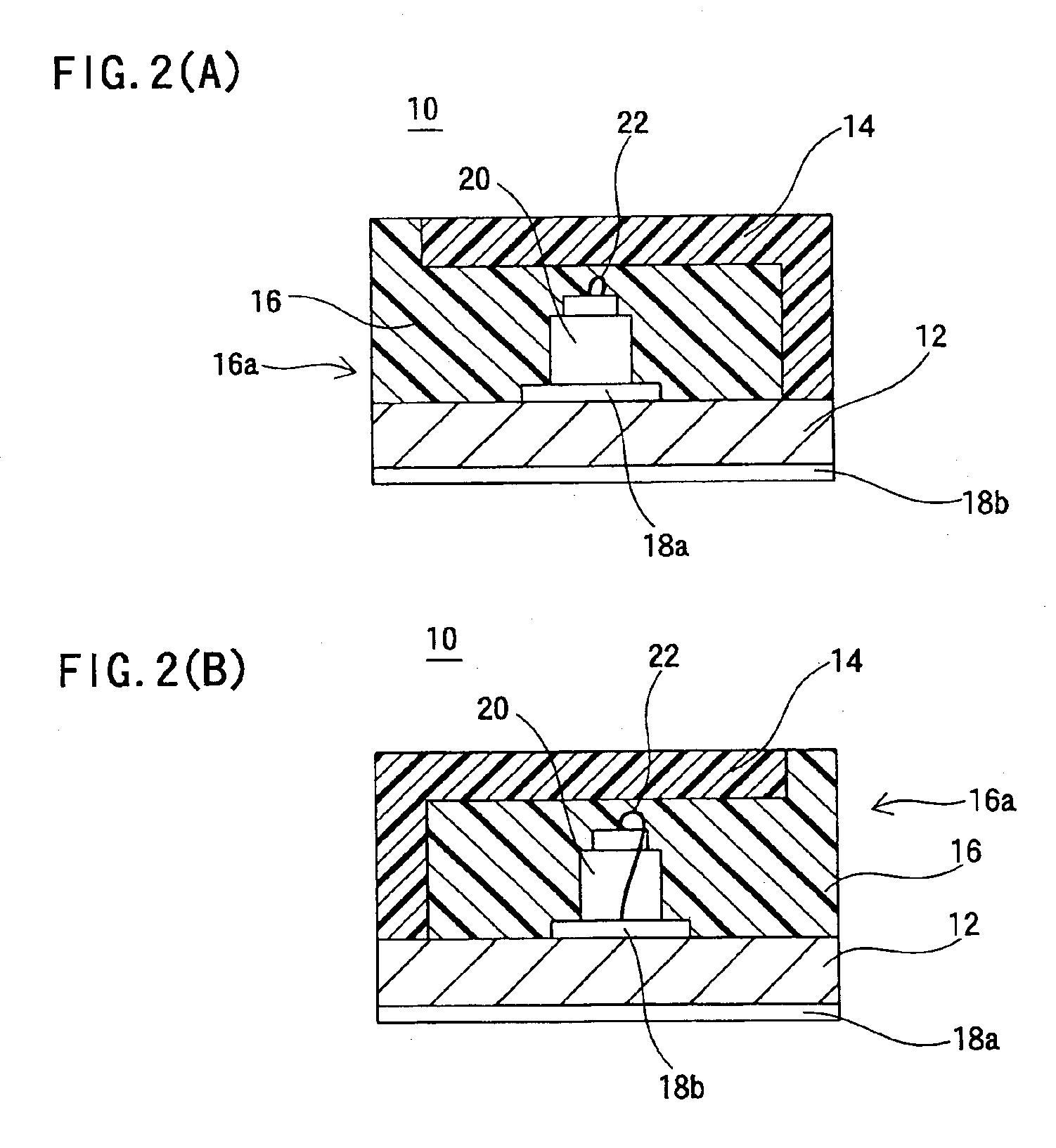

[0064]Referring to FIG. 1, a side-emission type semiconductor light-emitting device (hereinafter referred merely to as “light-emitting device”) 10 of this embodiment includes an insulating substrate (hereinafter referred merely to as “substrate”) 12 formed of a glass epoxy or the like. On the substrate 12, a reflector (case) 14 formed of a resin having opacity and reflectivity is provided. The substrate 12 is provided with electrodes 18a and 18b, and as can be understood from FIG. 2(A) of cross-sectional view at a line IIA—IIA in FIG. 1, a semiconductor light-emitting element (LED chip) 20 is die-bonded onto the electrode 18a by a DB paste (not shown). Meanwhile, as can be understood from FIG. 2(B) of a cross-sectional view at a line IIB—IIB in FIG. 1, the electrode 18b and the LED chip 20 are electrically connected with each other by a bonding wire 22 such as a gold wire and etc.

[0065]The electrode 18a is formed to extend from a front side to a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com