Wooden container and a process for manufacturing thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051]Embodiments of the present invention are described in detail, referring to drawings.

An Embodiment of the Wooden Container

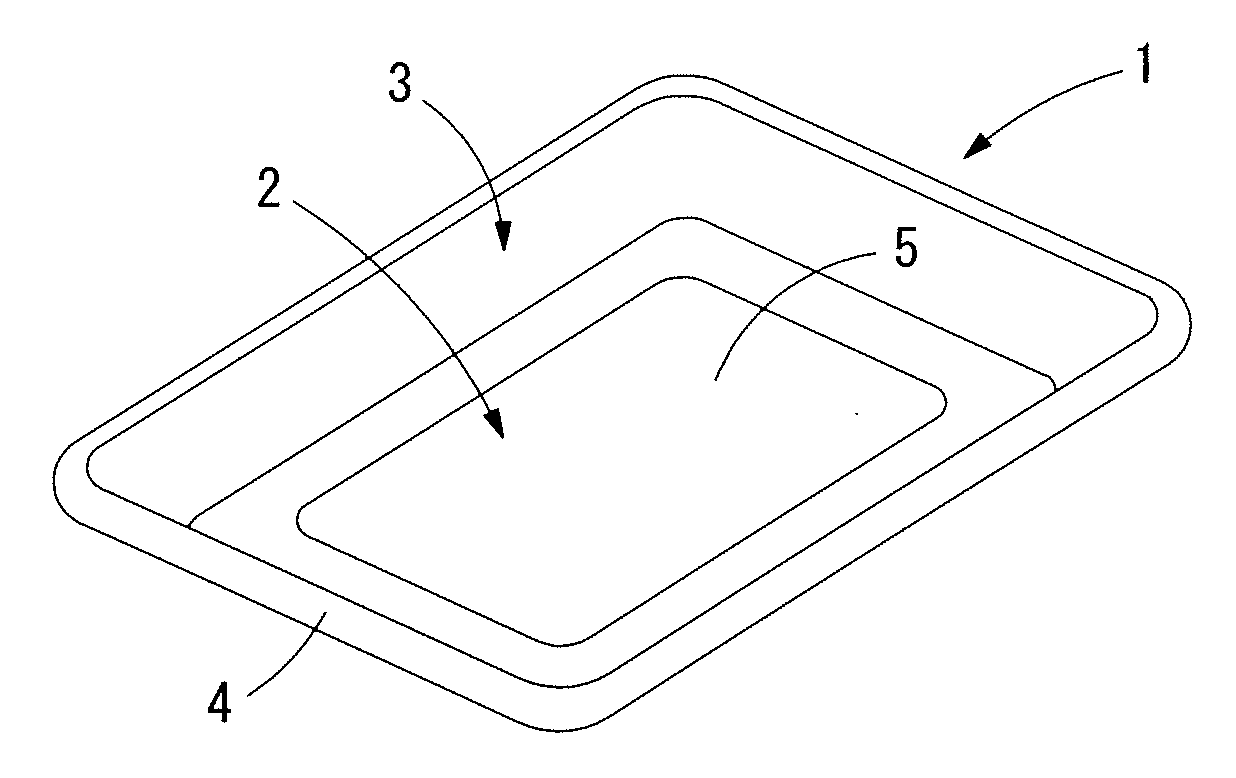

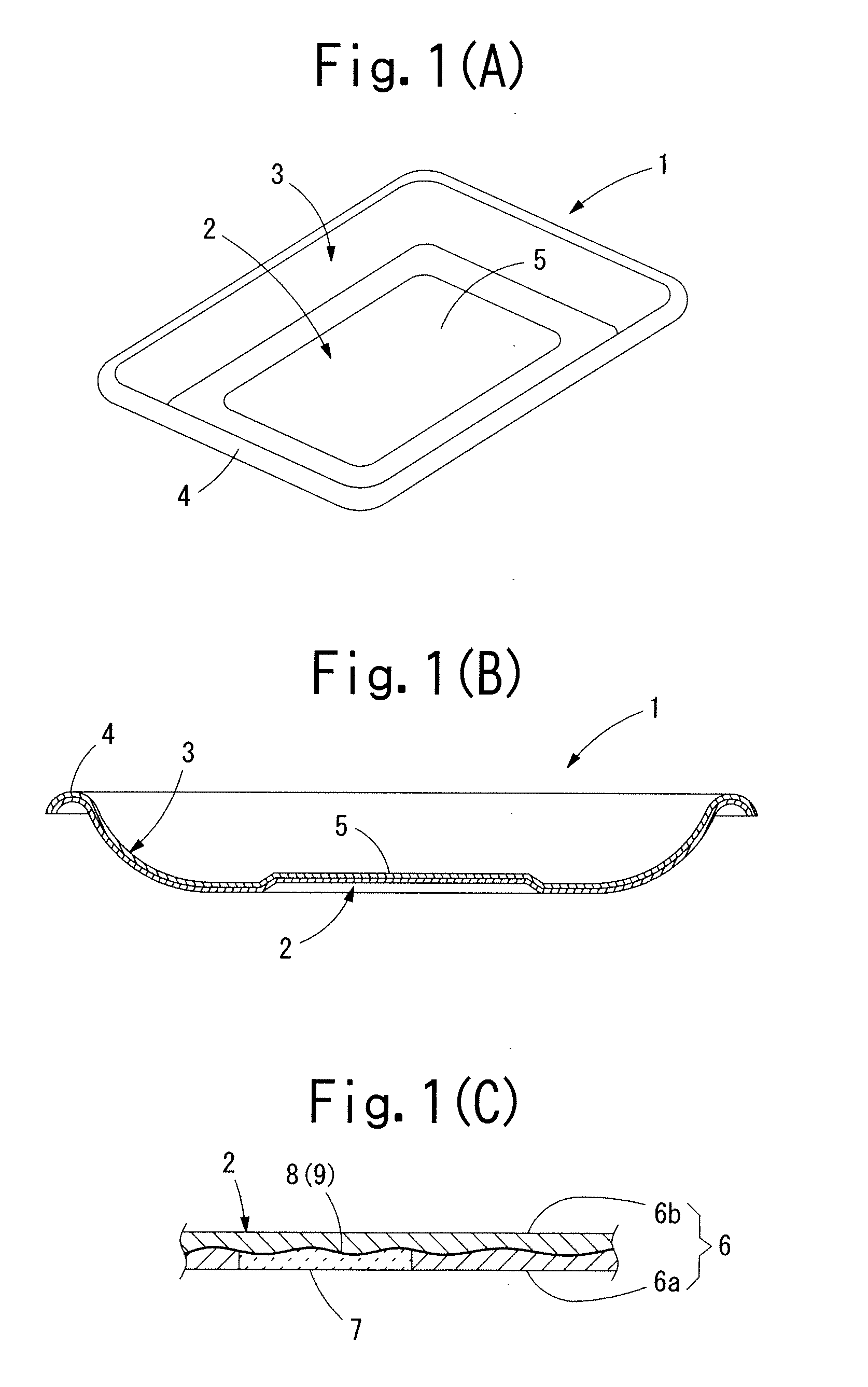

[0052]In FIG. 1, a wooden container 1 is illustrated as a tray, for example, having a bottom wall 2 and a peripheral wall 3, the tray may be shaped in either shallow or deep configuration. The tray has a surrounding edge 4 extending along the upper opening edge of peripheral wall 3 and also extending downward as circular in cross section. A bulge portion 5 may be formed by slightly lifting the center of bottom wall 2 so that moisture of wet food and like packed in the container may stagnate below the circumference of the bulge portion 5.

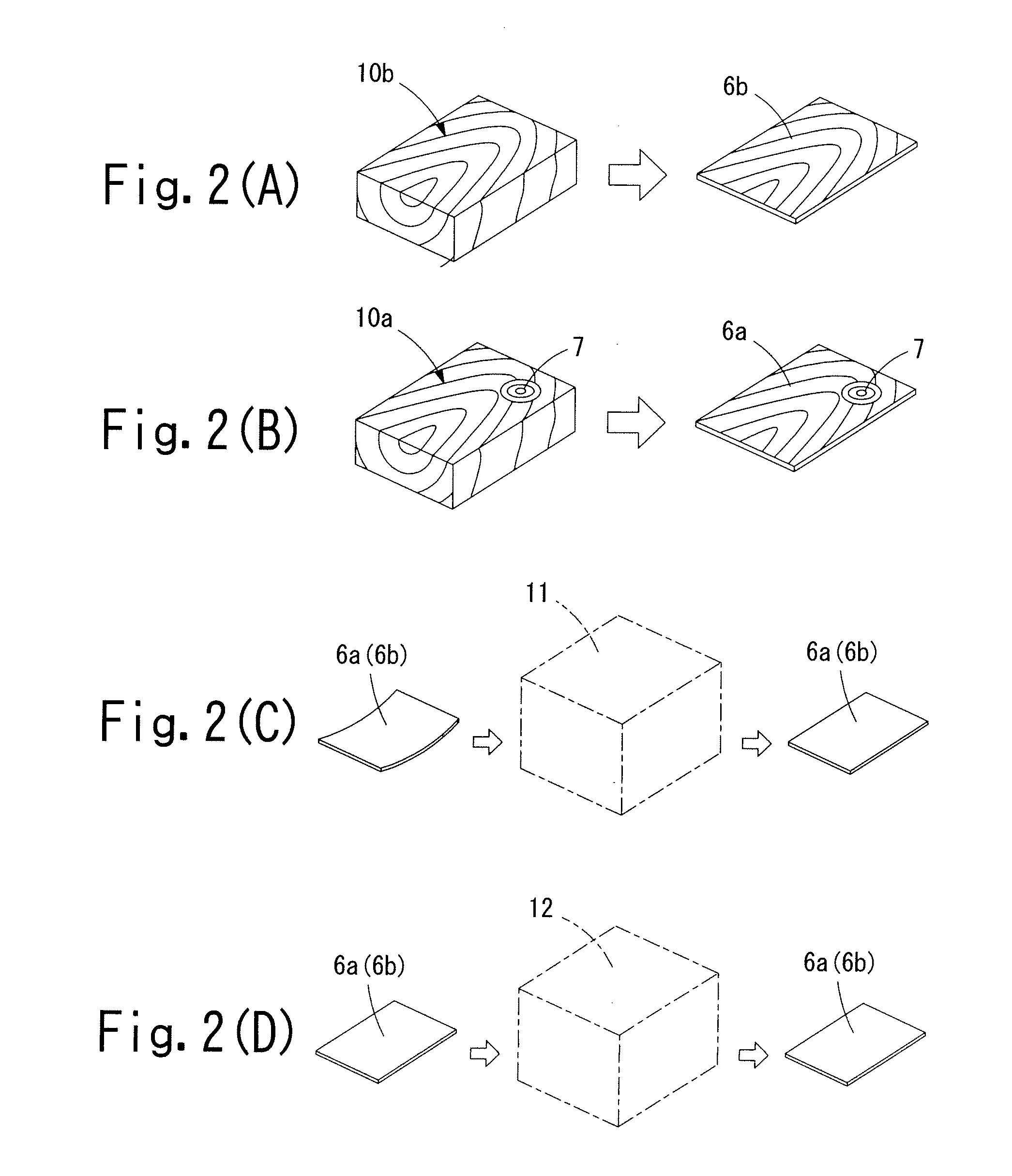

[0053]The wooden container 1 is formed by a plywood sheet 6 comprising an inferior sheet 6a having spoiled portions such as knot or crack and a superior sheet 6b having no such spoiled portion. The inferior sheet 6a and the superior sheet 6b are chosen from a large number of wooden sheets obtained by slicing a wooden piece. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com