Temperature compensating insert for a mechanically leveraged smart material actuator

a technology of smart material and compensating element, which is applied in the direction of valve housings, machines/engines, generators/motors, etc., can solve the problems of increasing the method suffers from several problems, and the length of the compensating element inserted between the main body and the smart material increases the overall length of the actuator, so as to reduce or eliminate the movement of the arms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

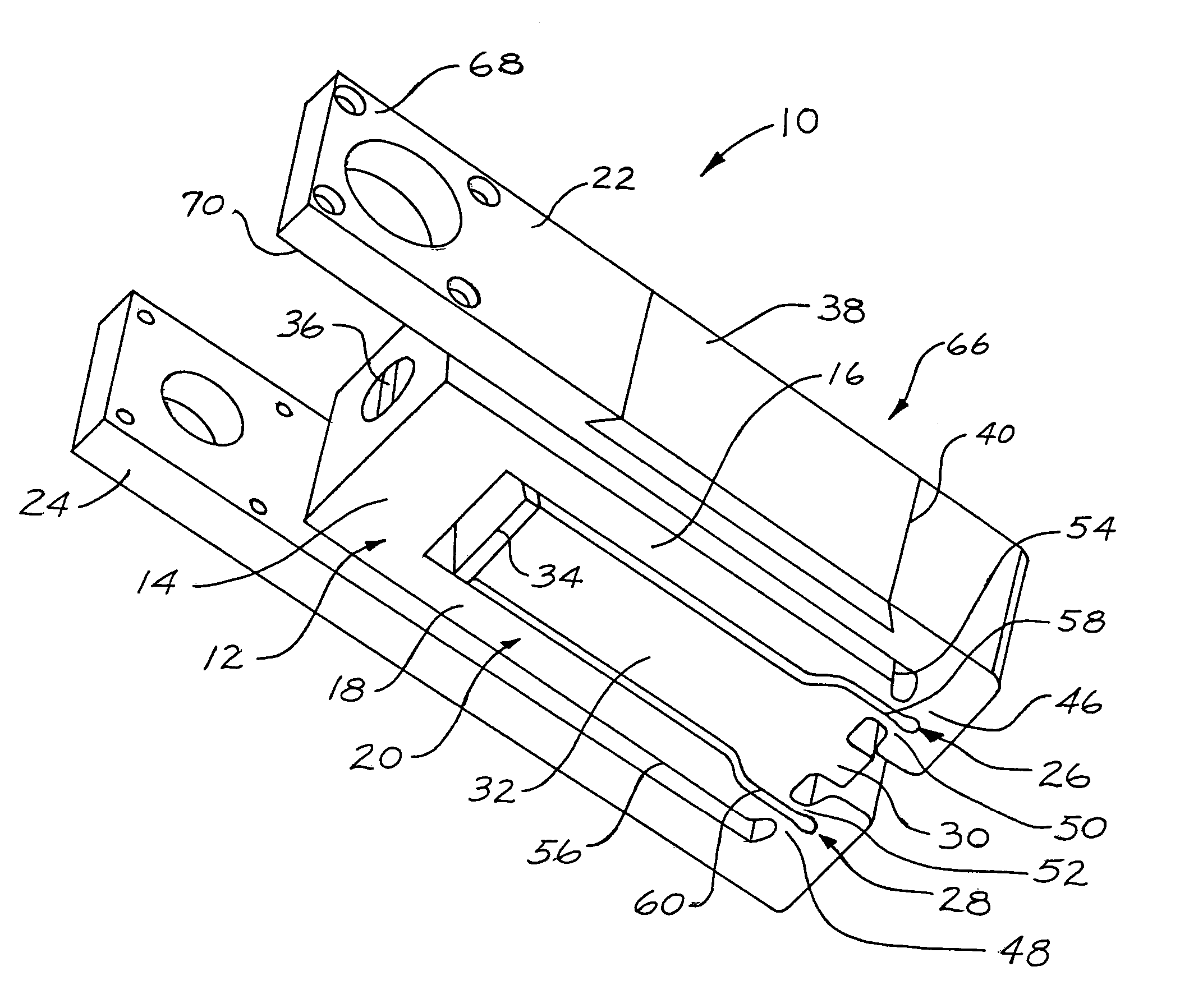

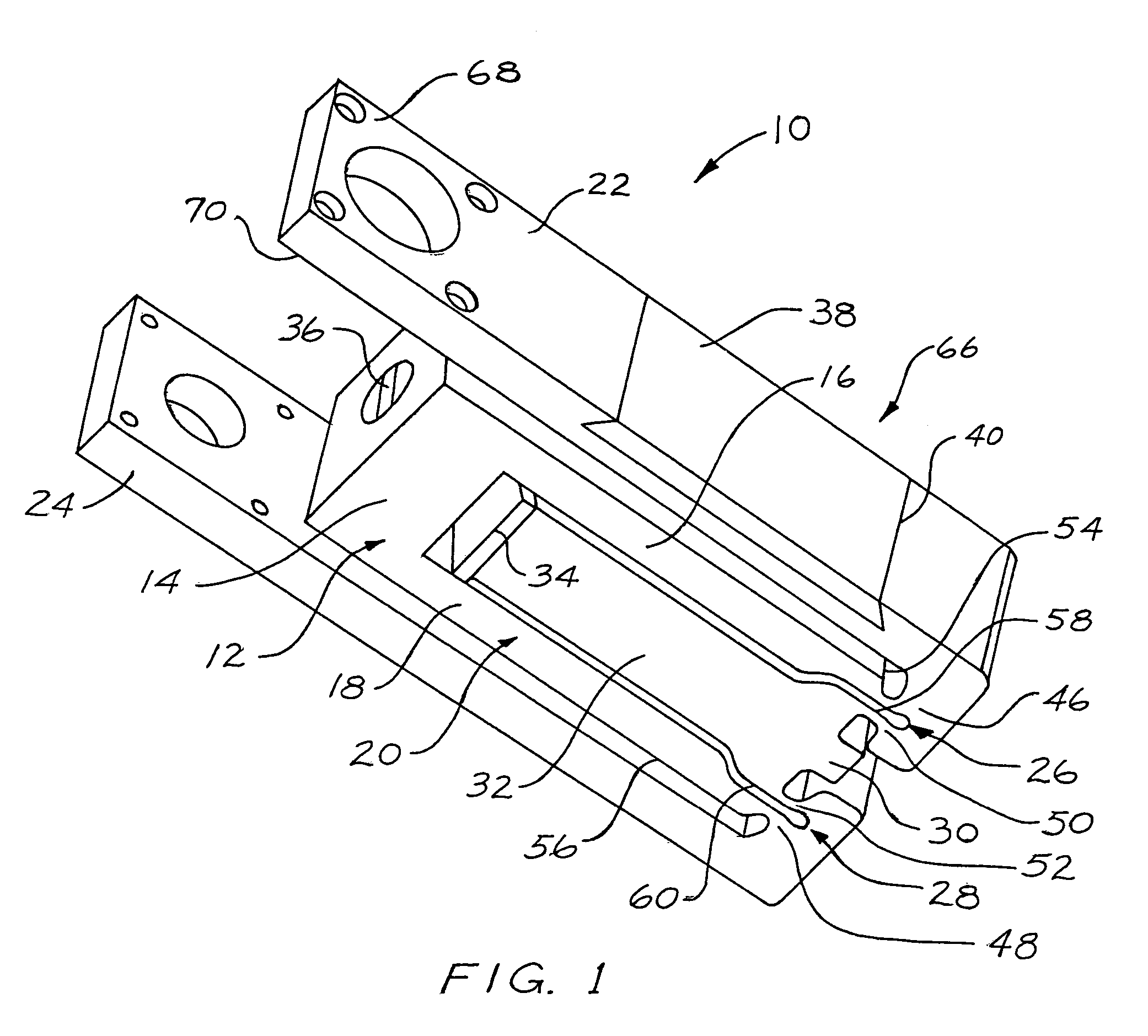

[0021]Referring now to FIG. 1, a perspective view of one embodiment of an apparatus 10 is illustrated having a support structure 12 including a non-flexing web portion 14 extending between an upper and a lower pair of rigid non-flexing side portions 16, 18 forming a C-shaped portion 20. At least one pivotable arm portion, such as a first arm portion, 22, or 24 is pivotably connected via a corresponding living integral hinge portion 26, or 28 to a corresponding side portion 16, or 18. Another pivotable arm, such as a second arm portion 24 can be optionally connected via a corresponding living integral hinge portion 28 to the other rigid side portion 18, if two opposing arms 22, 24 are desired. A force transfer member 30 includes a surface engagable with one end of a smart material actuator 32. The opposite end of the smart material actuator 32 engages with an adjustable seat 34. Adjustable seat 34 can be supported by an adjustable support screw 36, connected through the support struc...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap