Compact slurry preparation system for oil sand

a technology of oil sand and slurry, which is applied in the direction of gas current separation, working up pitch/asphalt/bitumen by selective extraction, and separation processes, etc., can solve the problems of reducing affecting the quality of oil sand, and affecting the production efficiency of oil sand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034]The present invention is concerned with processing as-mined oil sand at the mine site to convert it to a pumpable slurry which is capable of being hydrotransported through a pump and pipeline system.

[0035]This is preferably done using an assembly of components which are compact and relocatable, so that the assembly can follow the advancing mine face. The components may be mobile, for example by being mounted on driven tracks, or they may be adapted for easy disassembly for periodic moving and reassembly. The term ‘relocatable’ is intended to describe both versions.

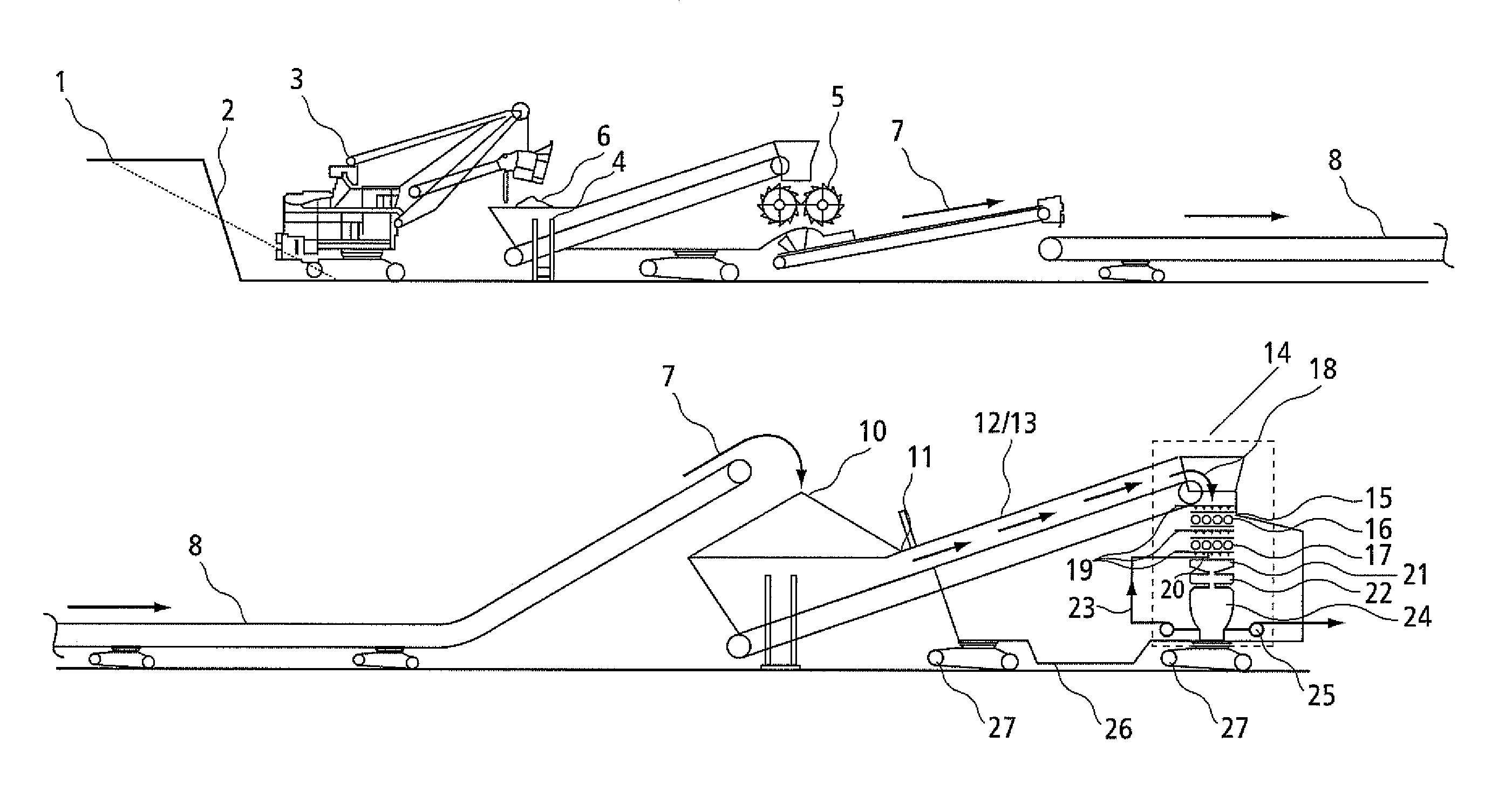

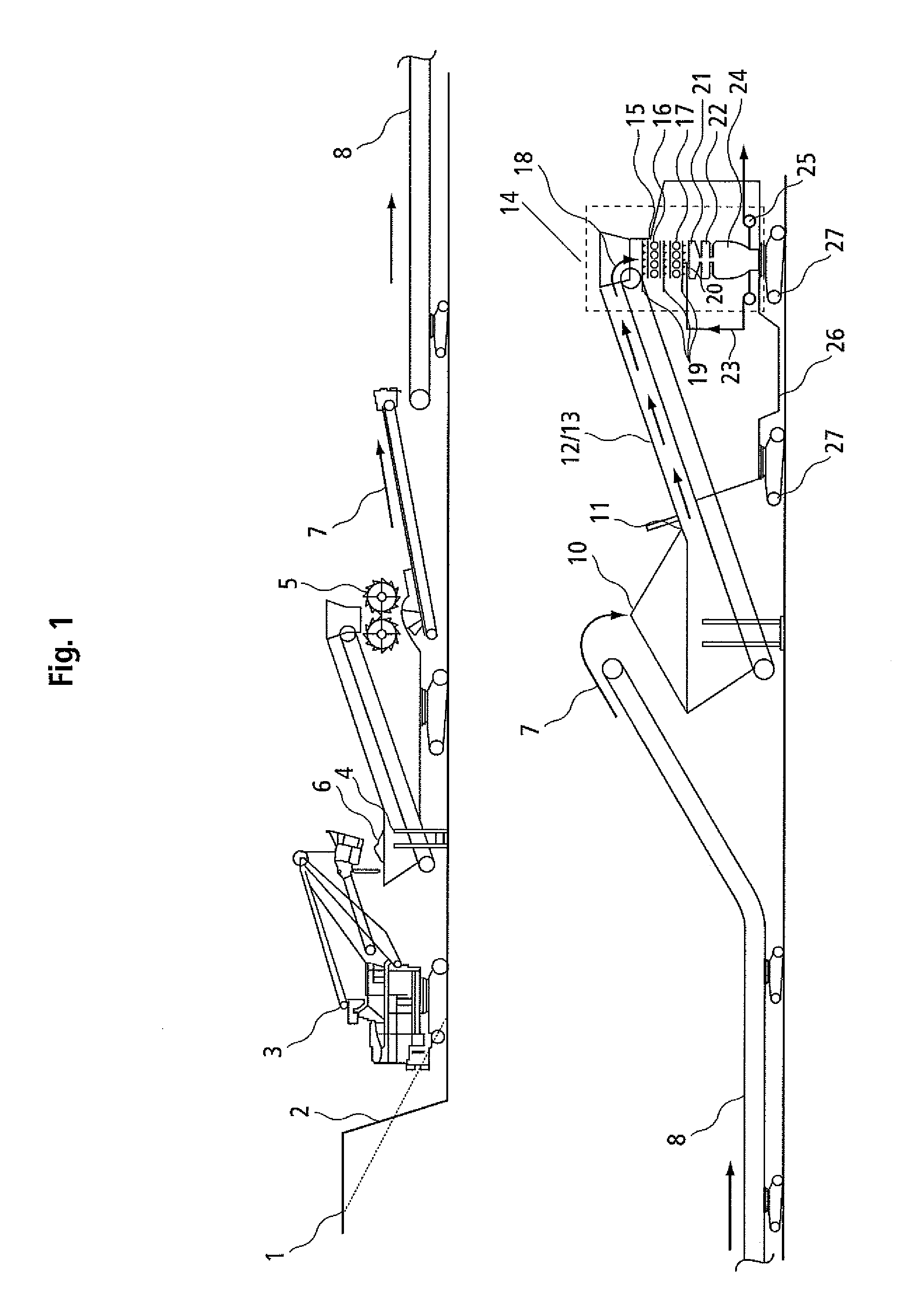

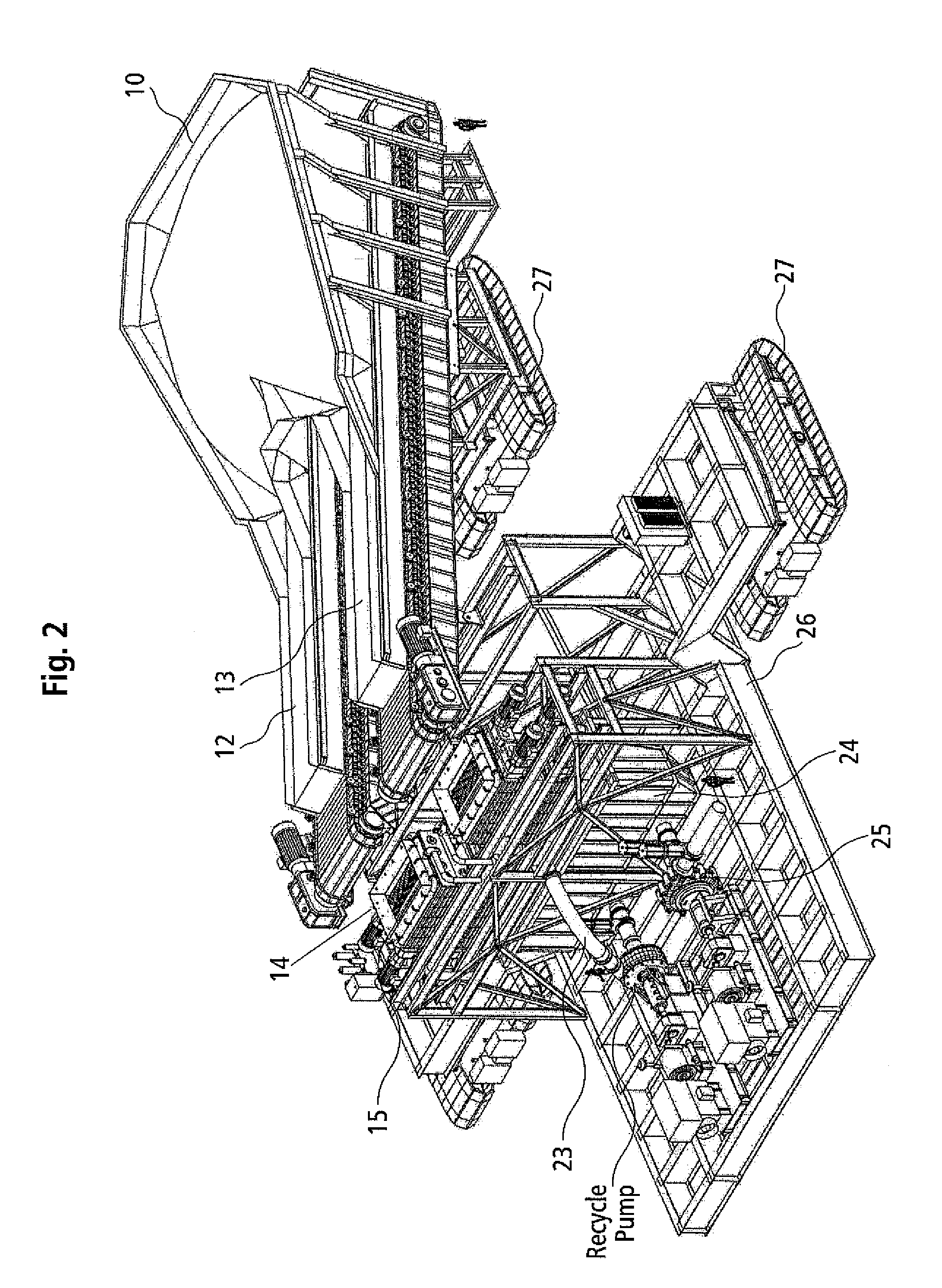

[0036]Turning now to the specific embodiment shown in FIG. 1 the oil sand 1 is excavated at a mine face 2 using a mobile shovel 3. The shovel 3 dumps the as-mined material into the hopper 4 of a mobile primary roll crusher 5. The primary roll crusher 5 comminutes the as-mined oil sand 6 to conveyable size (e.g. −24 inches). This comminuted oil sand 7 is referred to below as ‘pre-crushed’ oil sand.

[0037]The pre-crushe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| weights | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com