Boring device

a technology of boring device and punching unit, which is applied in the field of punching unit, can solve the problems of many parts of the camera type punching unit, and achieve the effect of reducing the number of sensors and reducing the cost of the punching uni

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

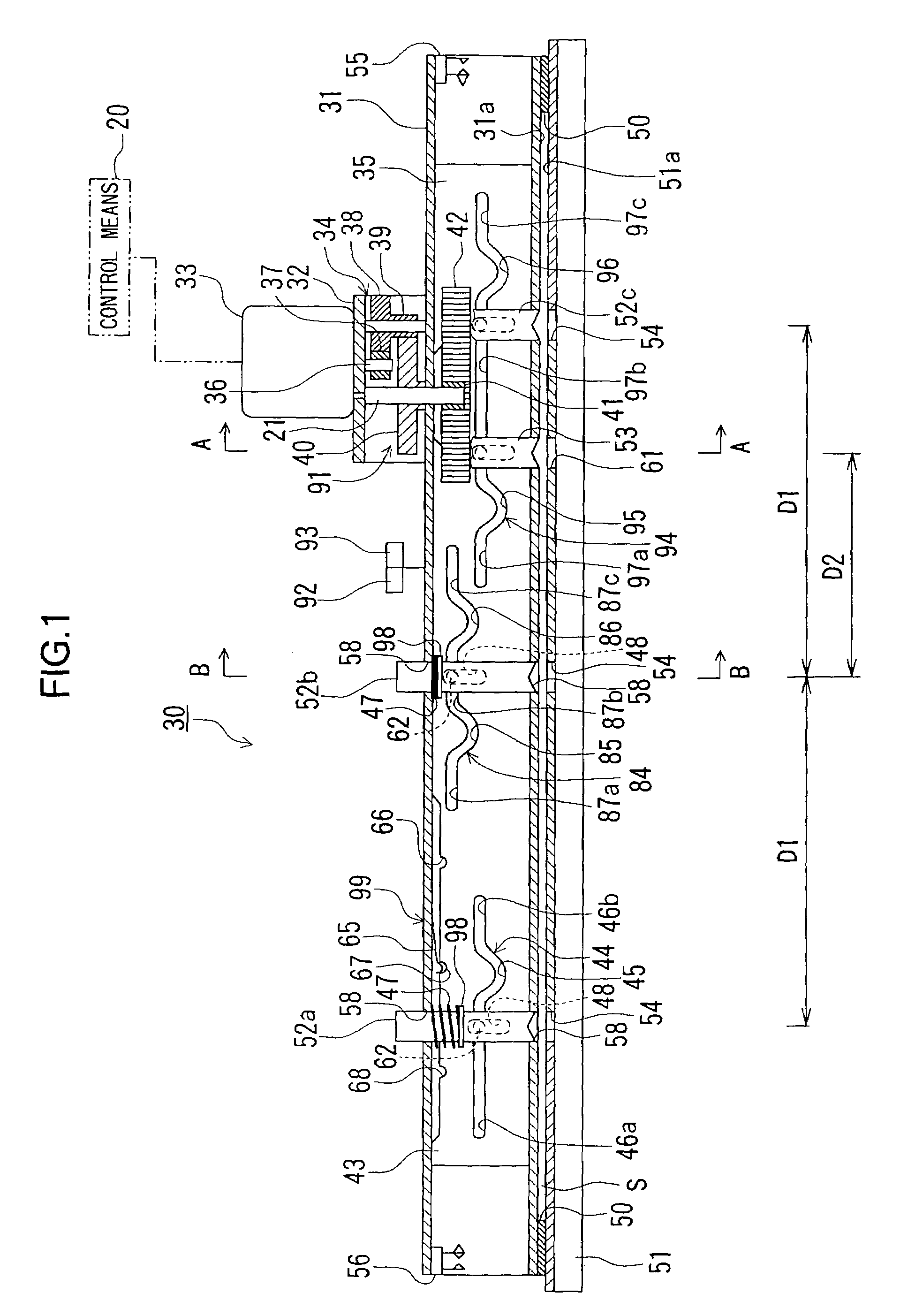

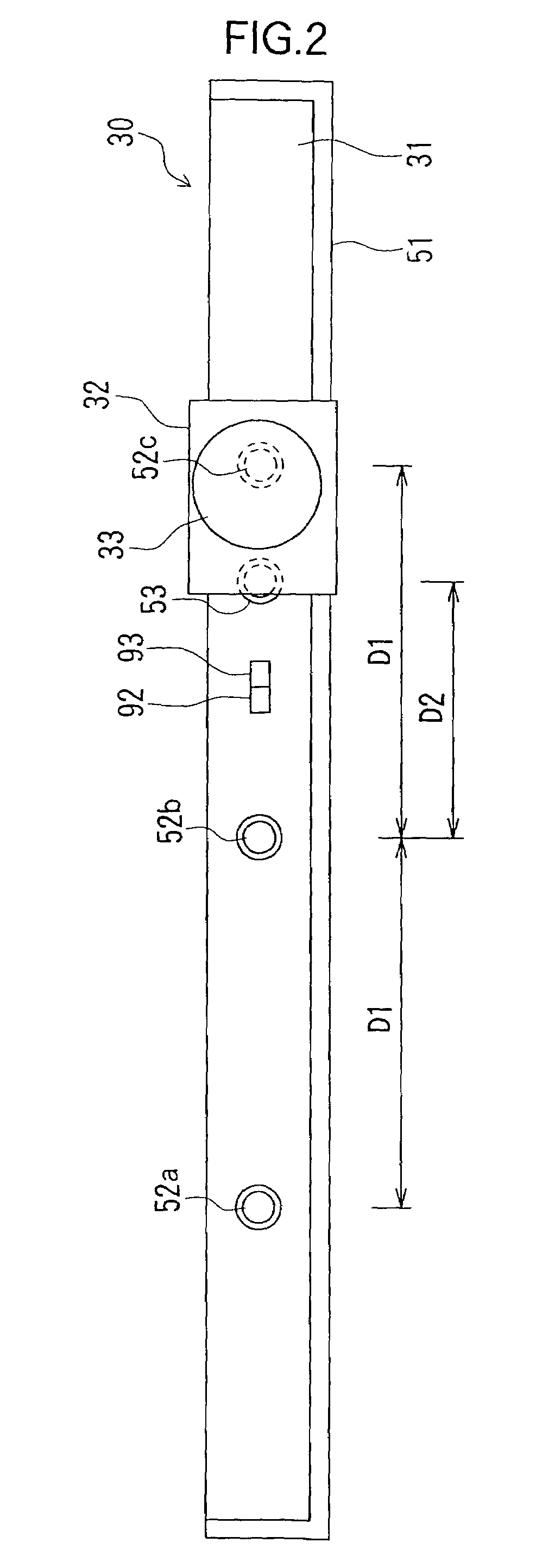

[0037]A first embodiment of an inventive punching unit will be explained below with reference to the drawings. FIG. 1 is a partially broken front view of the punching unit according to the first embodiment of the invention, FIG. 2 is a plan view of the punching unit in FIG. 1, FIG. 3 is a section view of the punching unit taken along a line A-A in FIG. 1, FIG. 4 is a section view of the punching unit taken along a line B-B in FIG. 1 and FIGS. 5A through 5C are section views of the punching unit for explaining operations of the punching unit of the present embodiment.

[0038]As shown in FIGS. 1 and 2, the punching unit 30 of the present embodiment has a rectangle-tubular main frame 31, on which a motor 33 is disposed through an intermediary of a bracket 32. The motor 33 is linked to a lengthy cam plate (reciprocating member) 35 through an intermediary of a speed reducing gear mechanism 34 and functions as a driving source for moving the cam plate 35 in the lateral direction in FIG. 1. ...

second embodiment

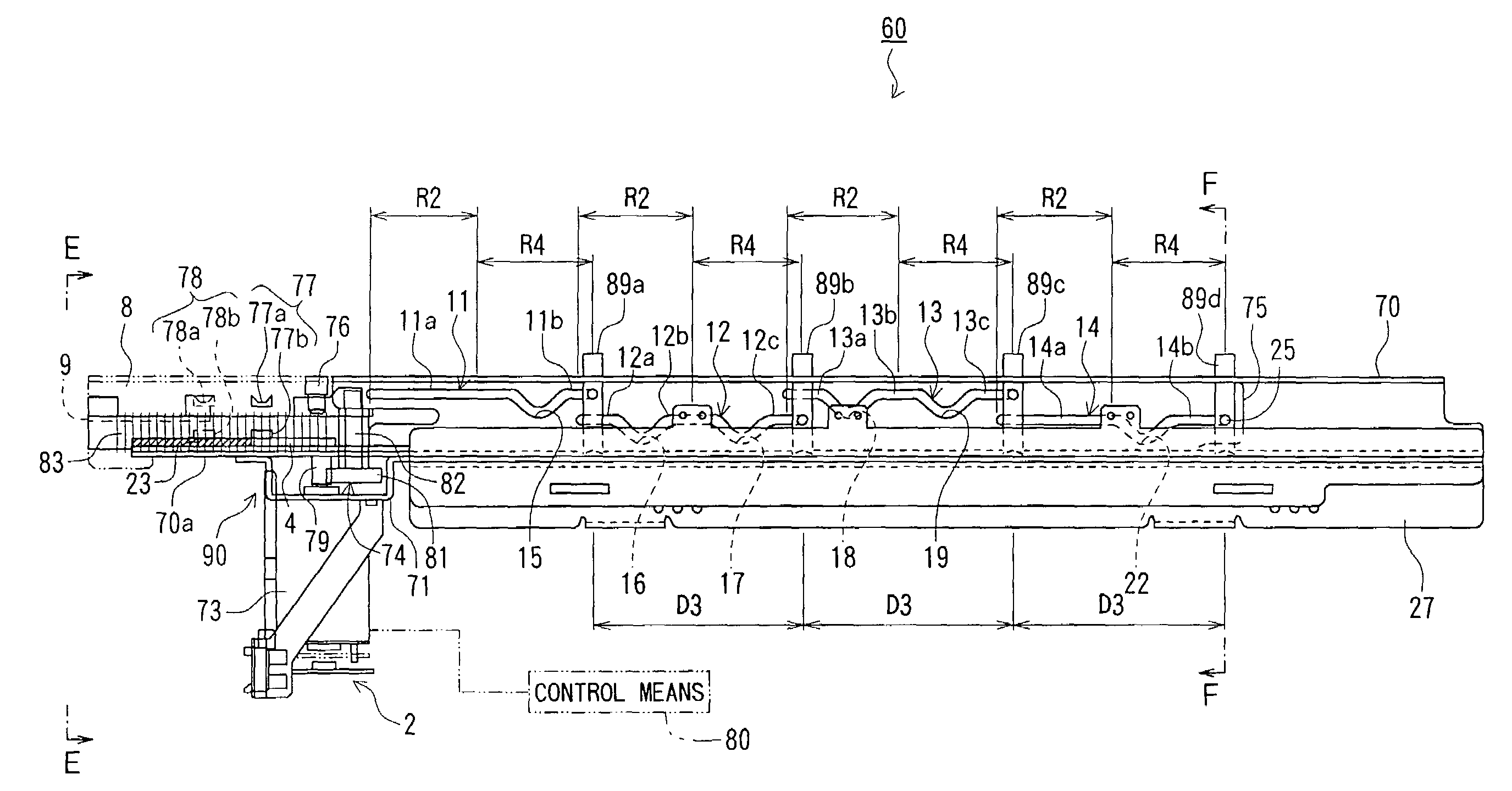

[0087]Next, a second embodiment of the inventive punching unit will be explained with reference to FIGS. 6 through 11. FIG. 6 is a partially broken front view of a punching unit according to a second embodiment of the invention, FIG. 7 is a plan view of the punching unit in FIG. 6, FIG. 8 is a bottom view of the punching unit in FIG. 6, FIG. 9 is a side view of the punching unit taken along a line E-E in FIG. 6, FIG. 10 is a side section view of the punching unit taken along a line F-F in FIG. 6 and FIG. 11 is a partially enlarged front view of a movable range detecting sensor, a rack and others in FIG. 6.

[0088]As shown in FIGS. 6 through 11, the punching unit 60 of the present embodiment is provided with a motor 73 on a main frame 70 through an intermediary of a bracket 71. The motor 73 is linked to a lengthy cam plate (reciprocating member) 75 through the intermediary of a speed reducing gear mechanism 74 and functions as a driving source for moving the cam plate 75 in the lateral...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electric power | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| rotational force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com