Door arrester

a technology for arresters and doors, applied in the field of door arresters, can solve the problems of undesirable fluctuations in the retaining force of door arresters, high manufacturing costs, and high cost of sheet metal blank manufacturing, and achieve the effect of effective damping and even more deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

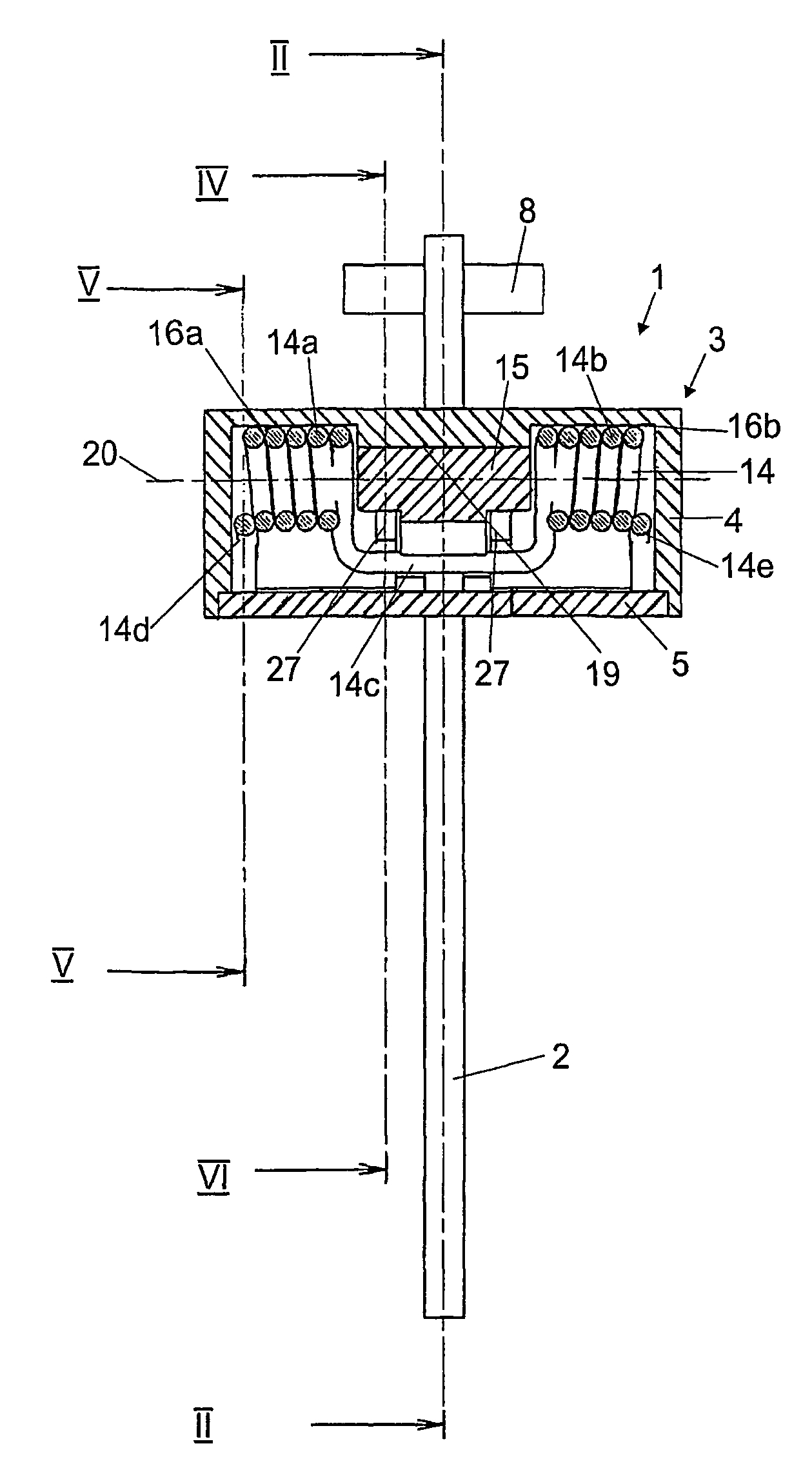

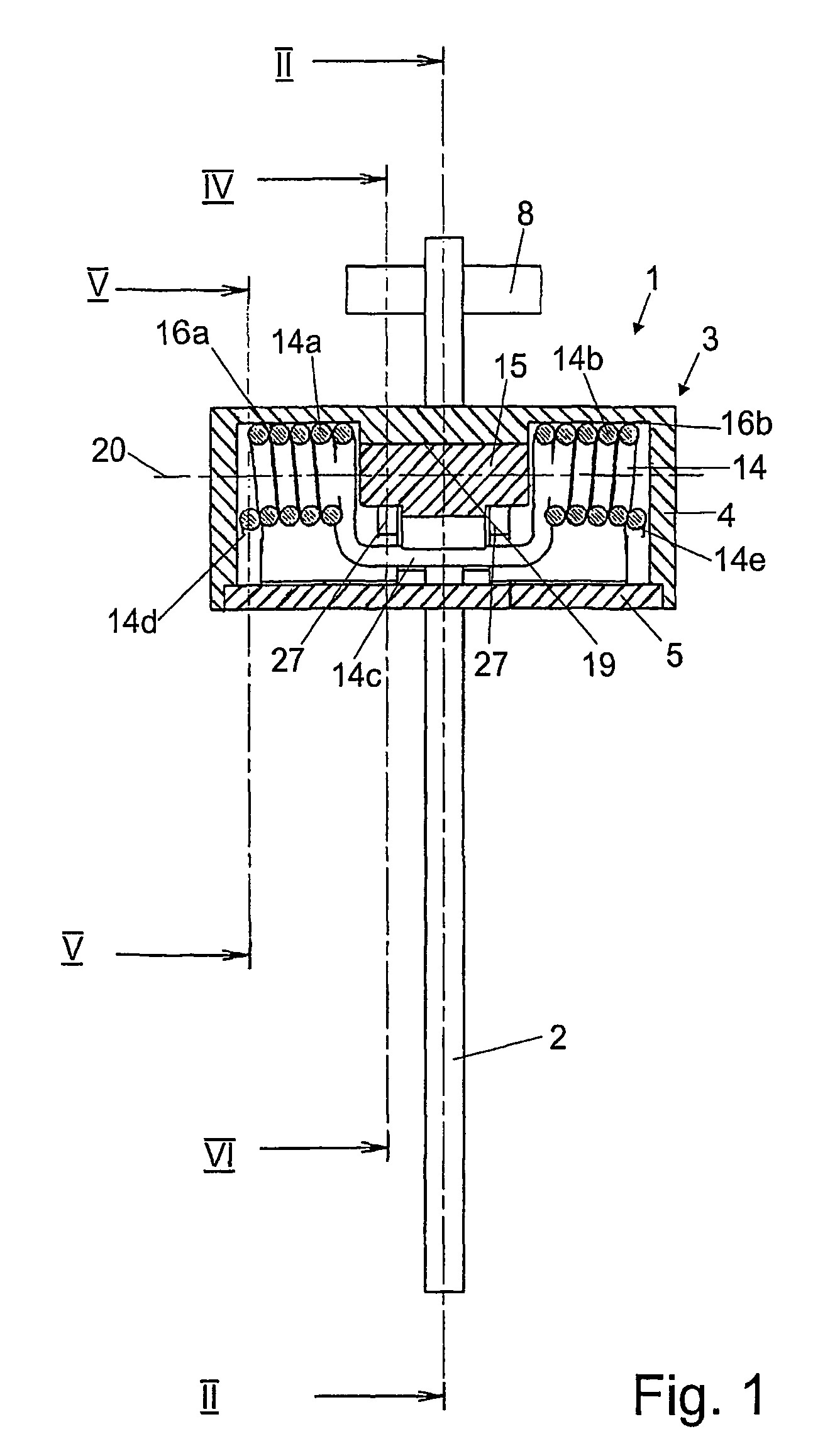

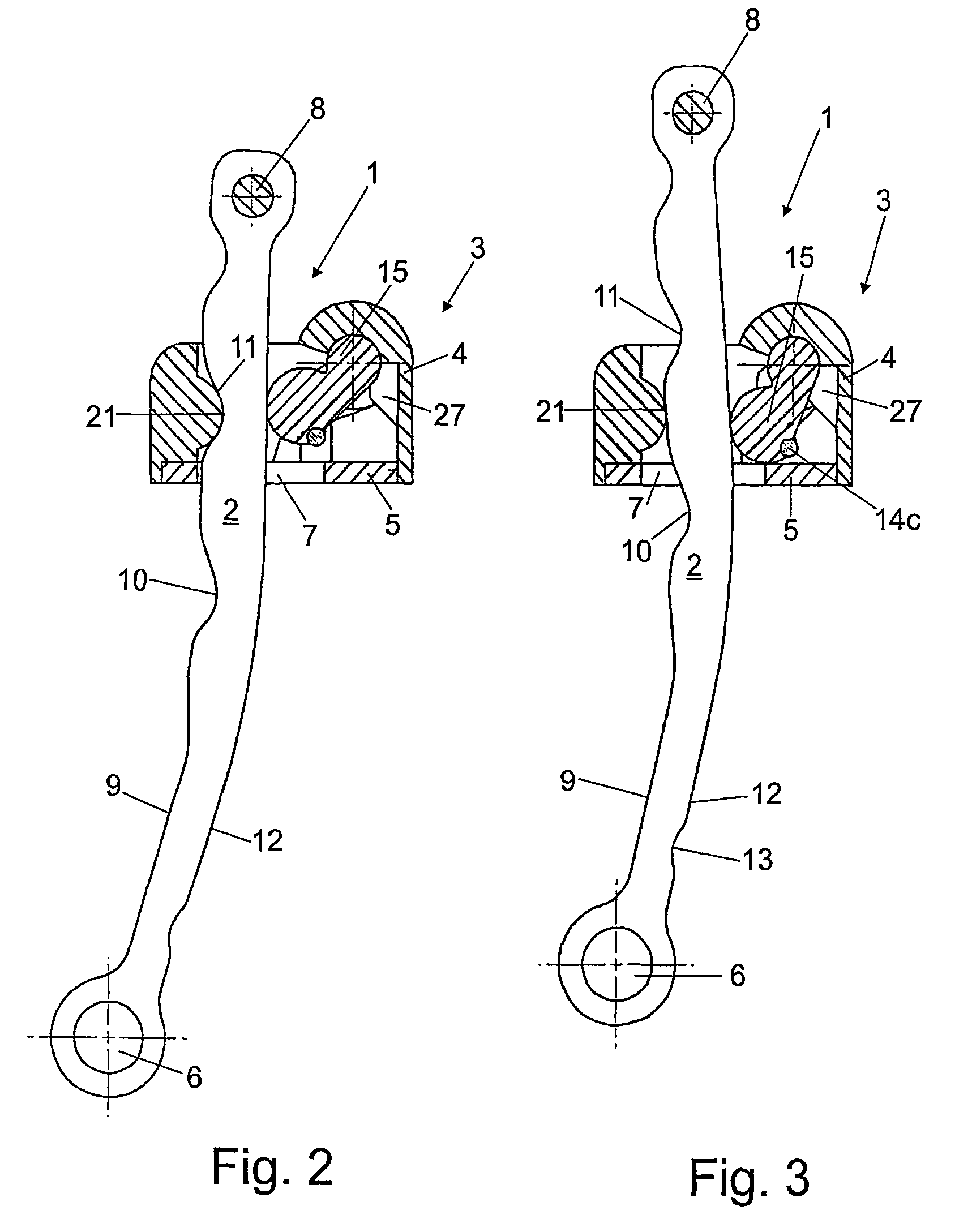

[0063]The door arrester illustrated in FIGS. 1 to 6, which is referred to overall by reference number 1, comprises a retaining bar 2 and a housing 3, which is composed of a first housing part 4 and a second housing part 5 which both consist of plastic and are clipped to each other.

[0064]The retaining bar 2 has, at its one end, a bearing eyelet 6 for fastening it pivotably to a door assembly part, for example to a door of a motor vehicle, and is guided through an opening 7 of the housing 3, a stop 8, which passes through the other end of the retaining bar 2, preventing the retaining bar 2 from tearing out of the housing 3 and restricting the pivoting path of the door. The retaining bar 2 is designed, for example, as a metallic blank of flat material which can be produced by stamping or forging, it being possible for this purpose also for a plurality of blanks of flat material, for example two, to be placed on one another and to be connected to one another in the region of the bearing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com