Floorboard having locking mechanisms comprising polymer

a technology of locking mechanism and polymer, which is applied in the field of floorboard, can solve the problems of large amount of material waste, excessive machining, and the process of manufacture not only requires special machineries and laborious handling, and achieves the effect of reducing the amount of material waste and extensive machining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034]The following examples are presented in a non-limitative manner.

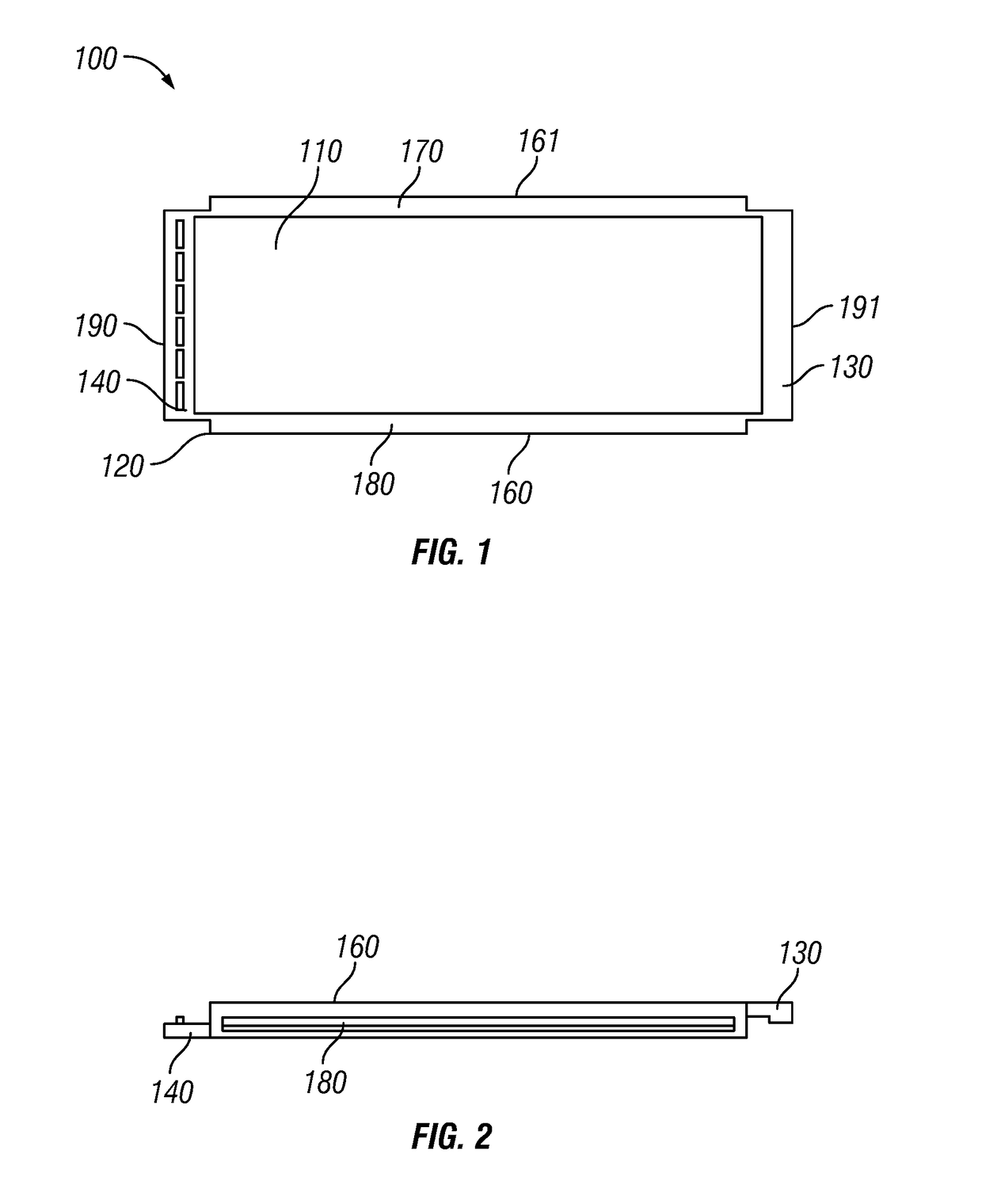

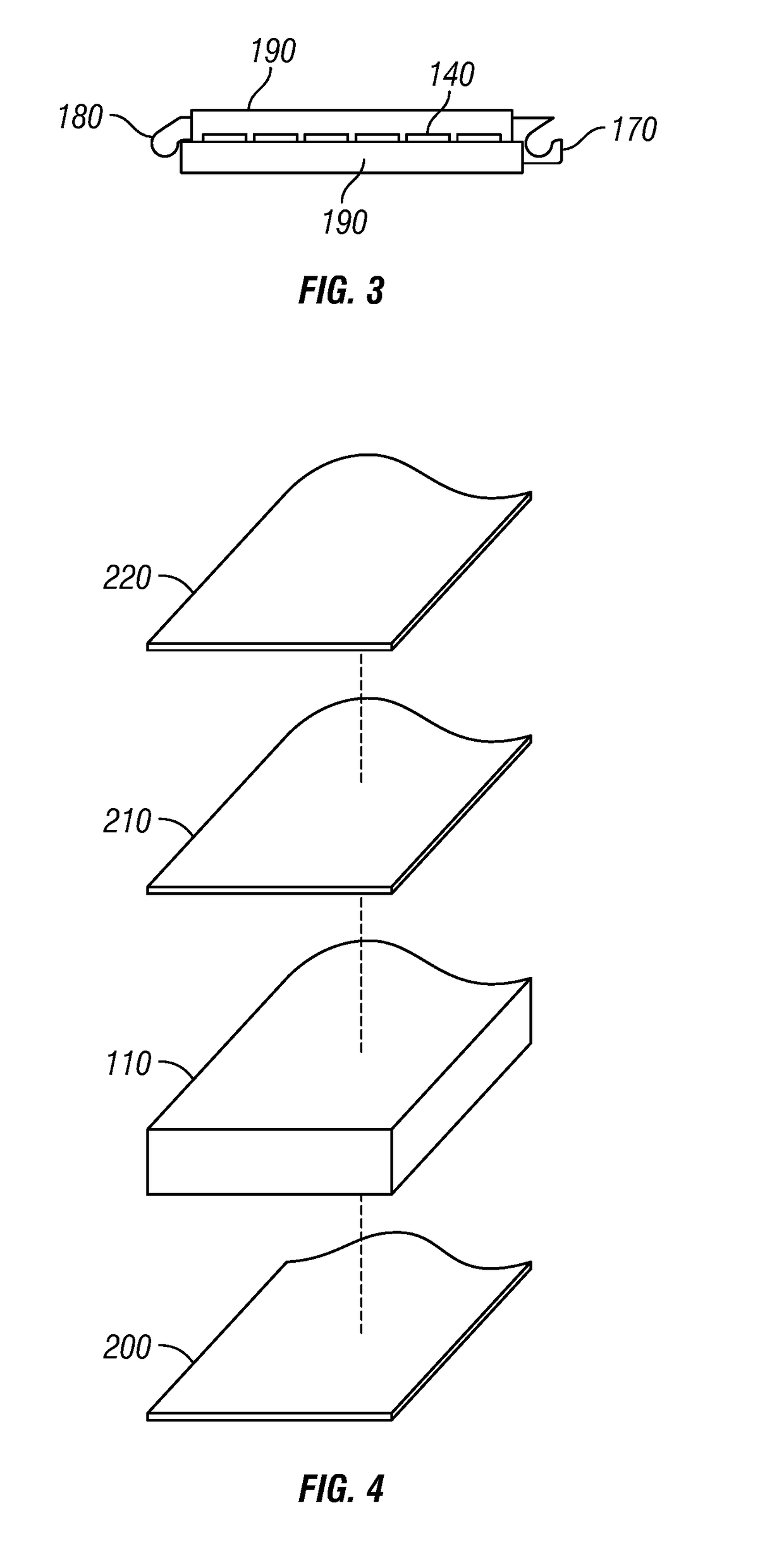

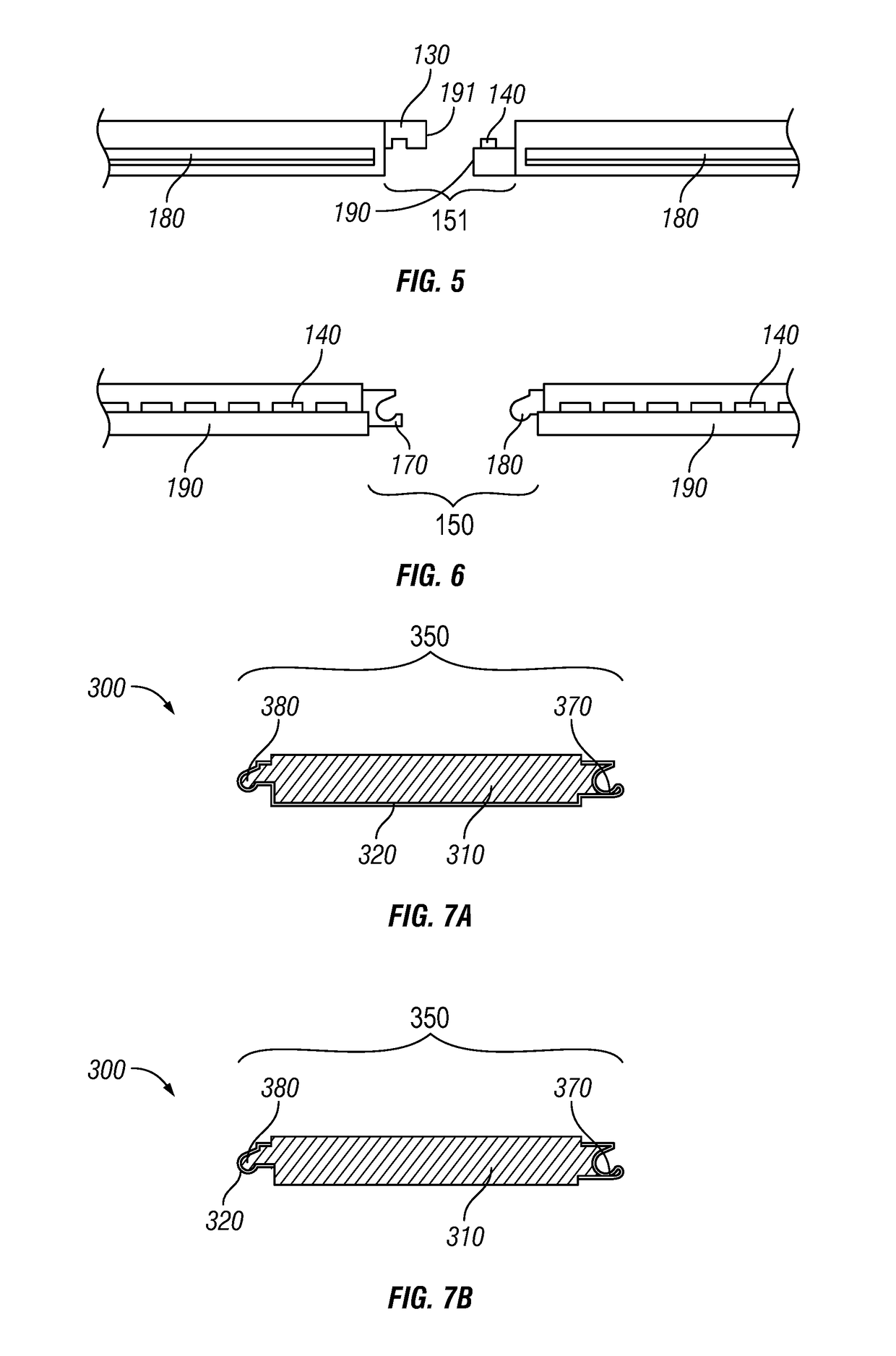

[0035]The expression “tongue and groove” used herein refers to a method of joining two objects together by means of fitting a tongue on one board into a matching indentation or groove of another board. For example, such a joining can be done by inclining the boards with respect to one another and sliding the tongue of one board into the groove of the other board. Then, when removing inclination between the two boards so that they are both at same angle or both lying flat on a surface, the two boards are locked with respect to one another, thereby preventing sliding or movement of the boards with respect to one another.

[0036]The expression “drop and lock” used herein refers to a method of joining two boards together by means of fitting at least one flange or block protruding from an extension of one board into a matching groove extending from the other object. For example, a “drop and lock” mechanism contrasts with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Shape | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com