Fastener bag

a technology of fastener and bag, which is applied in the direction of flexible container closure, transportation and packaging, sacks, etc., can solve the problems of affecting the working efficiency of the bag, the cutting-starting portion of the cut-open portion, and the inability to form well, so as to improve the content filling efficiency and facilitate the opening. , the effect of improving the self-standing performan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050]Hereunder, embodiments of the present invention will be described with reference to the accompanying drawings.

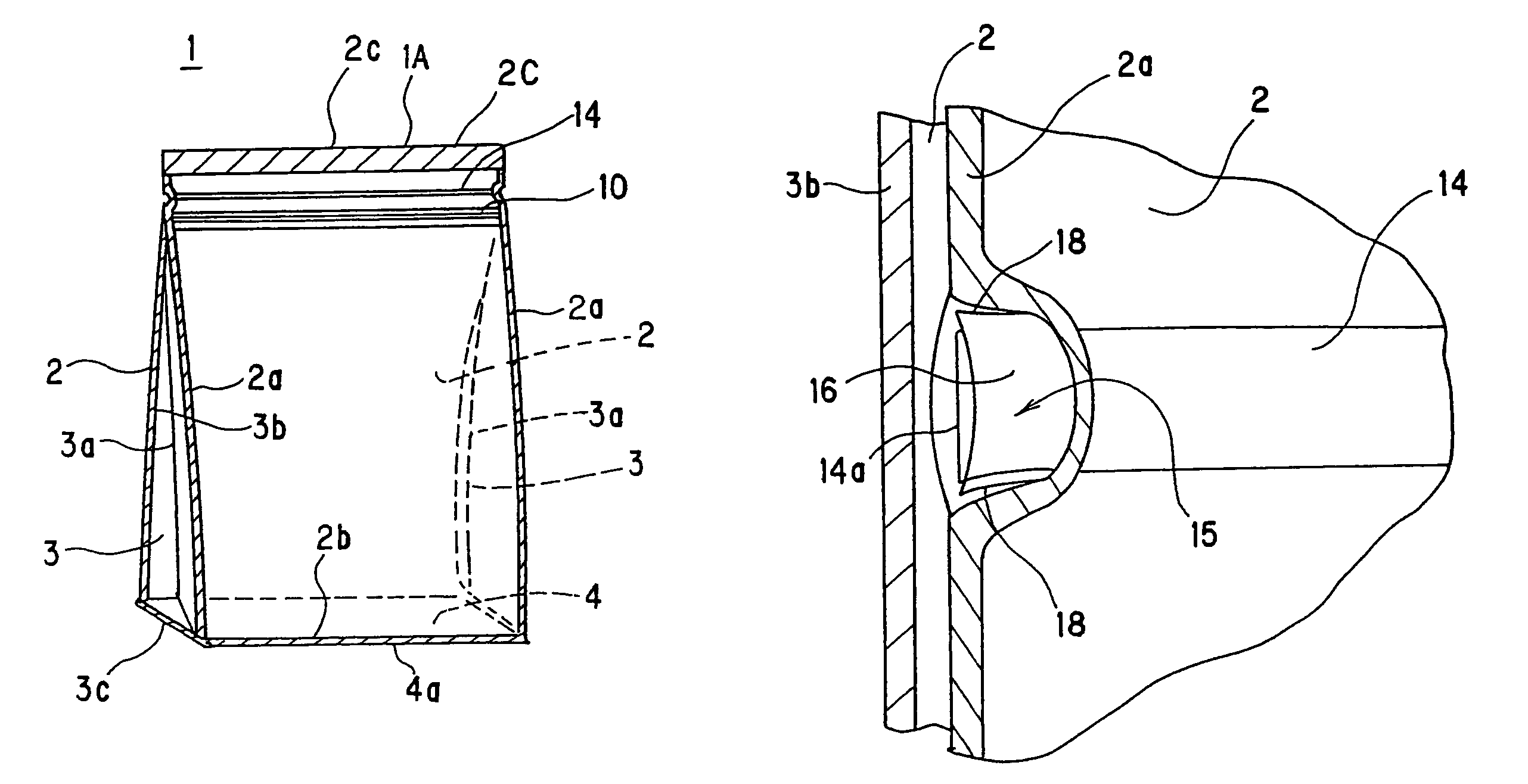

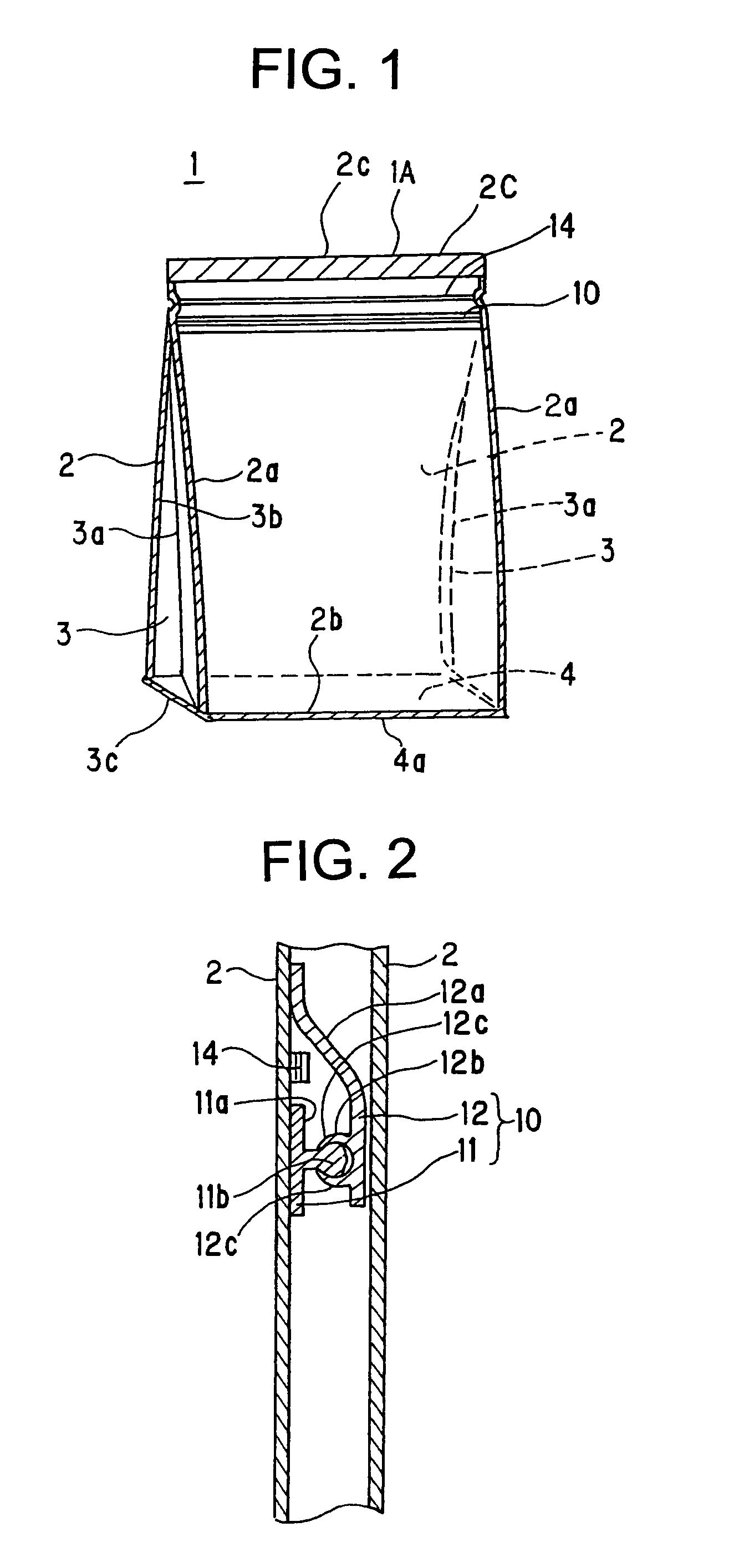

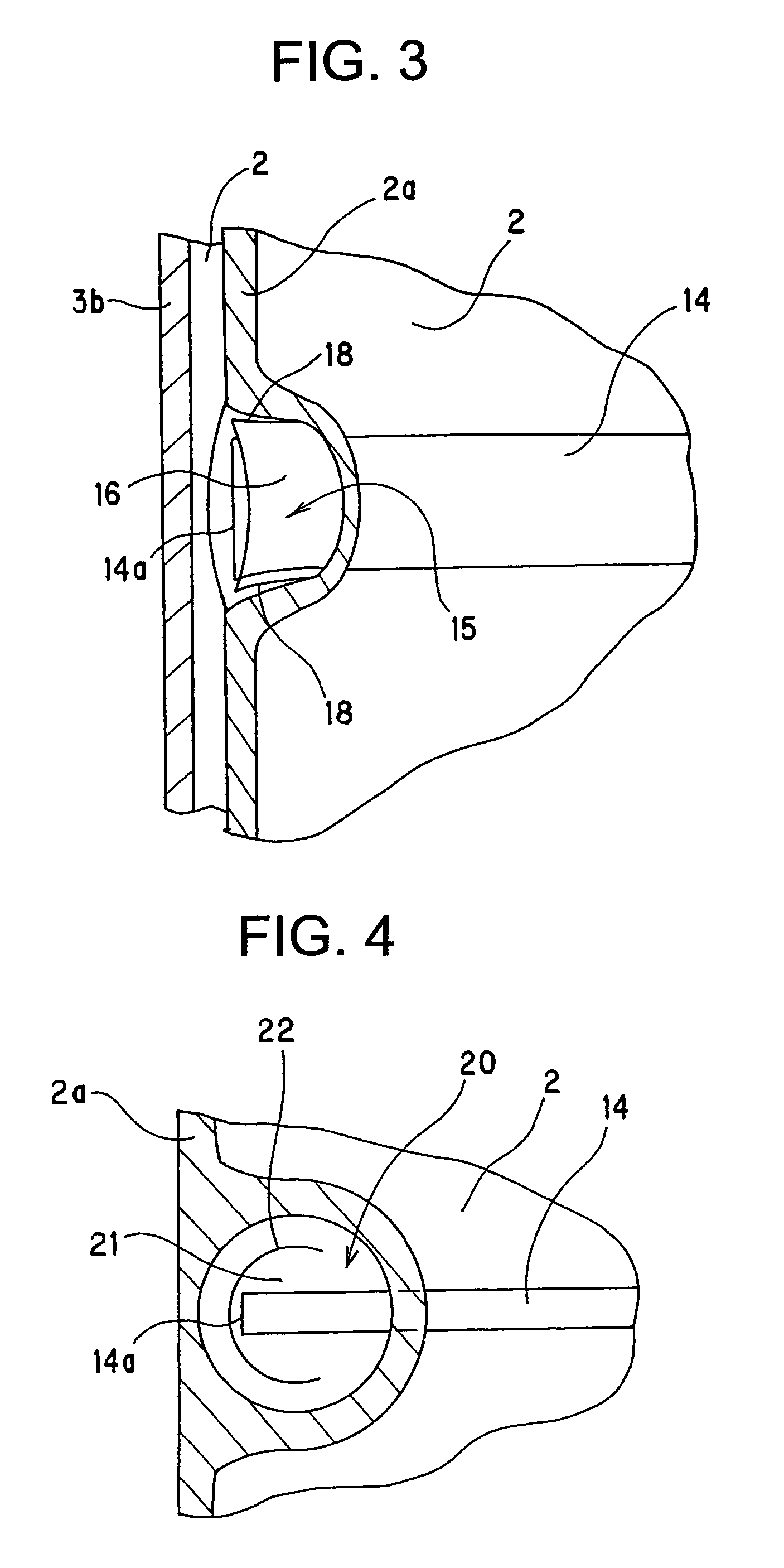

[0051]FIGS. 1 to 3 show a fastener bag 1 according to one embodiment of the present invention, in which FIG. 1 is a perspective view showing an entire structure of the fastener bag 1, FIG. 2 is an longitudinal sectional view of the fastener bag 1 showing an attached state of a fastener 10 for freely opening or closing the fastener bag 1, and FIG. 3 is an enlarged view showing a seal-opening starting portion of a cut-tape 14 for opening the fastener bag 1.

[0052]The fastener bag 1 is formed to have a rectangular shape having a pair of opposing flat surface portions 2, 2, side surface portions 3, 3 positioned at side edge portions 2a, 2a of the flat surface portions 2, 2, and a bottom surface portion 4 closing a bottom of the fastener bag 1. The fastener bag 1 is formed as a gusset-type packaging bag in which the side surface portions 3, 3 are folded inside along folding ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com