Hydrant roof mount

a technology for mounting brackets and roofs, applied in mechanical equipment, drawing-off water installations, transportation and packaging, etc., can solve the problems of lack of structural support, prone to leakage, and insufficient support of structures, etc., to facilitate interconnection, facilitate installation, and light and easy to install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

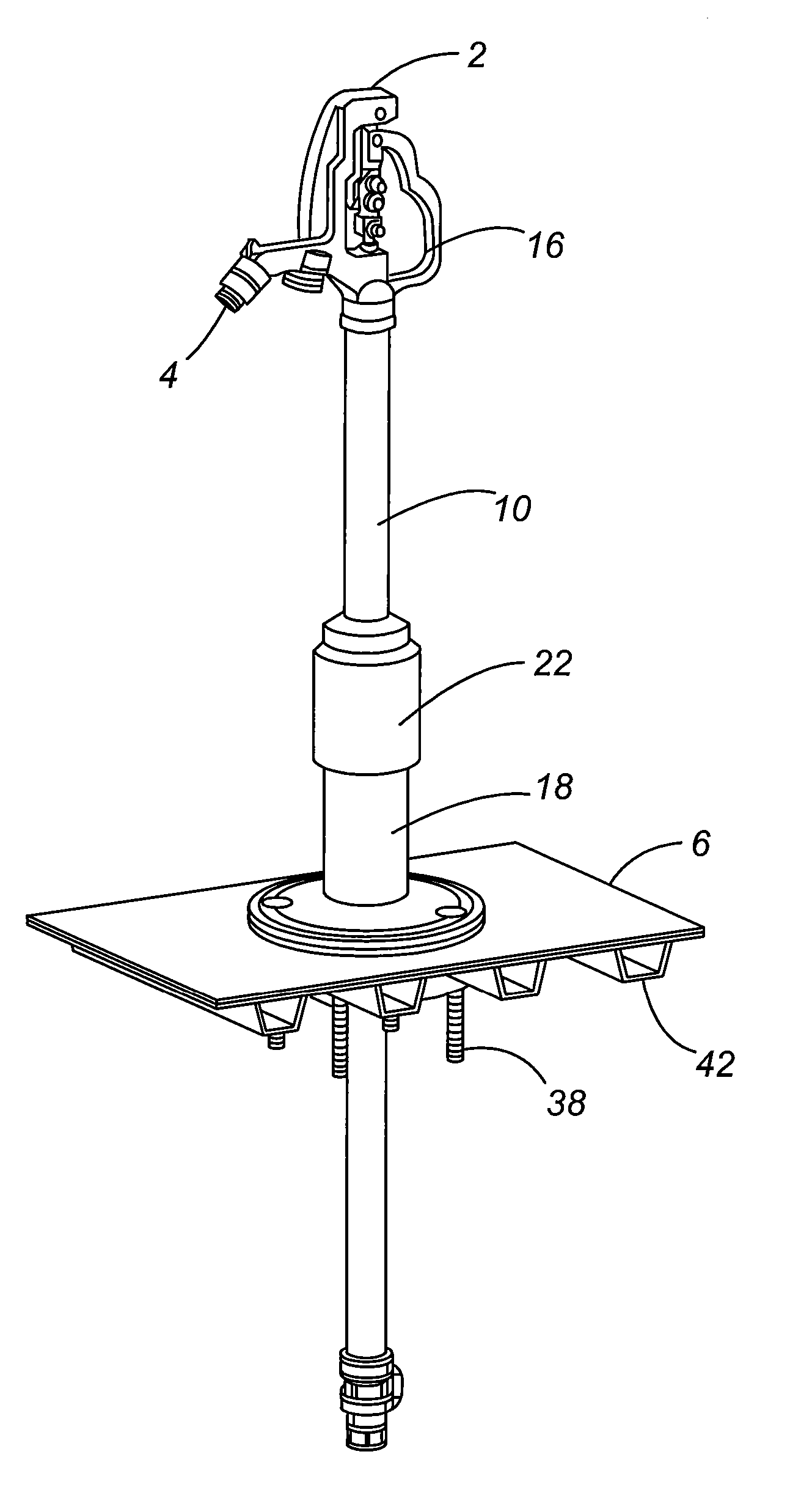

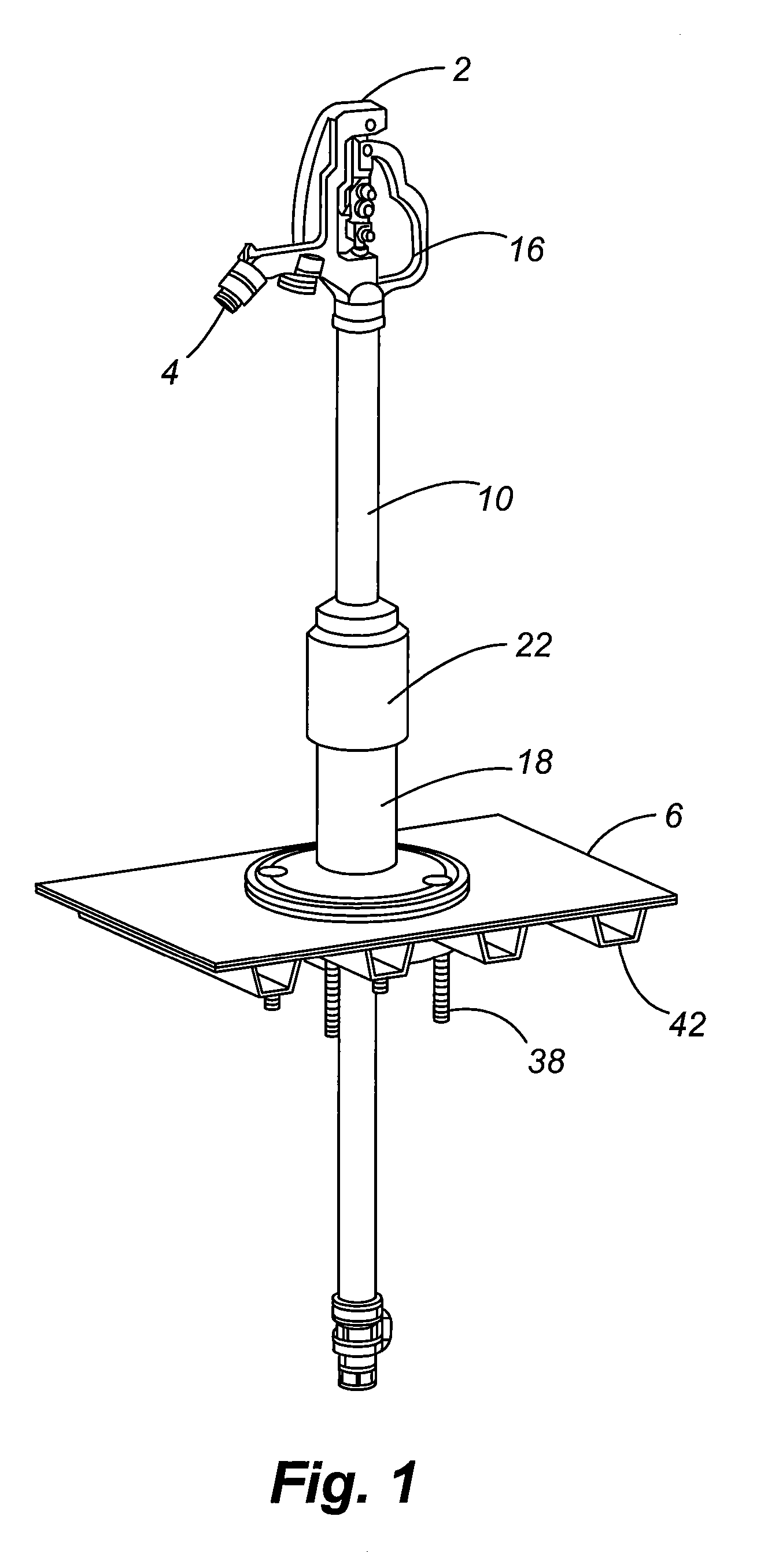

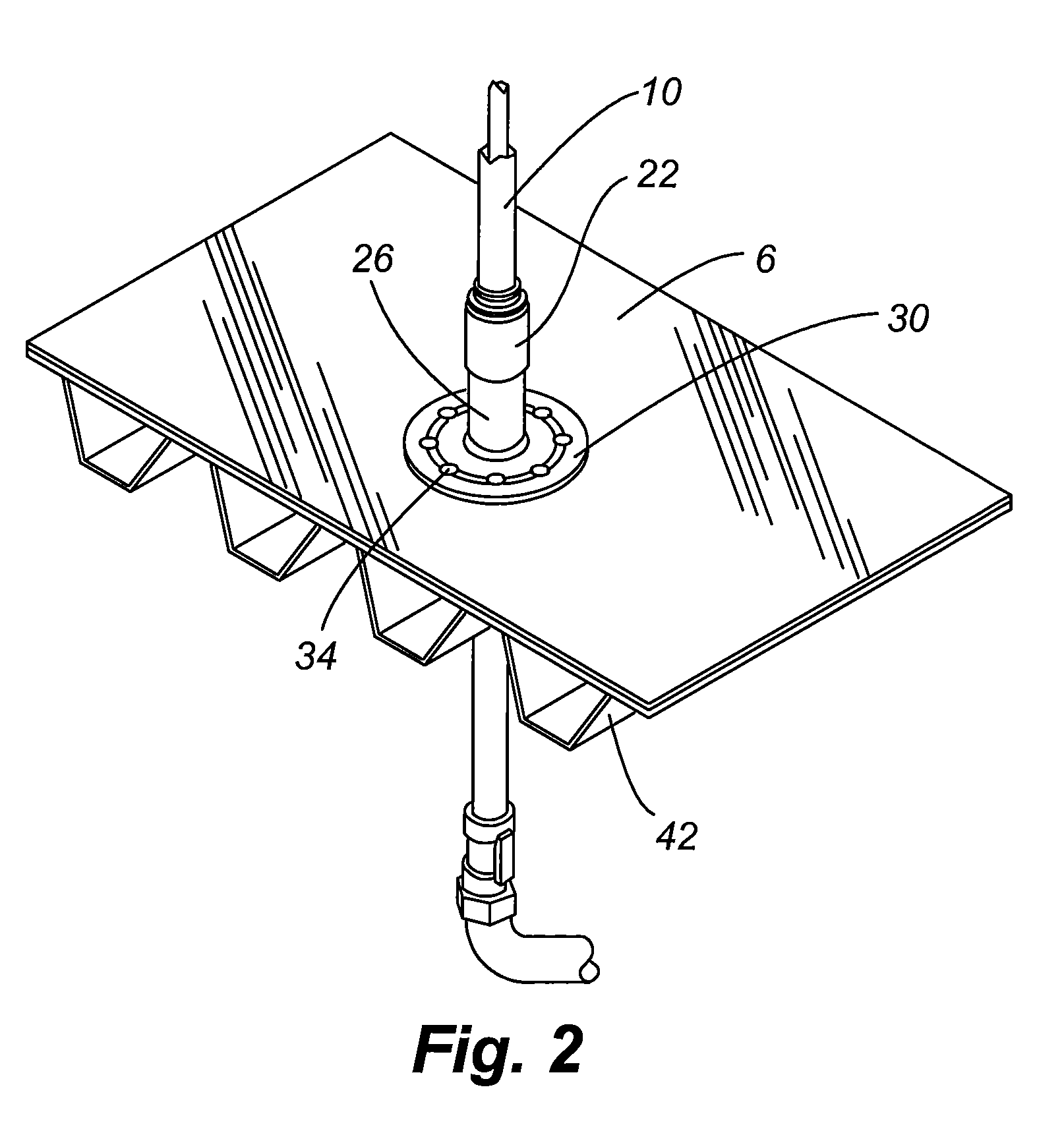

[0027]Referring now to FIGS. 1-12, a mounting system for securing a hydrant 2 to a roof deck 6 is provided. More specifically, embodiments of the present invention are used with a common hydrant 2 having a standpipe 10 that leads to a water supply 14. In the illustrated embodiment, the standpipe 10 is eventually interconnected to a water supply 14 that selectively is opened via a handle 16 of the hydrant 2. A hydrant support 18 provides rigidity to the standpipe 10. In order to ensure that substantially no fluid infiltrates into the inside of the building, a seal assembly 84, which includes an upper well seal 86, an intermediate seal 94, and a bottom seal 98, is employed that interfaces with the standpipe 10 and the hydrant support 18. A boot 22 may also be included to further provide leak resistance.

[0028]Referring now to FIGS. 1-6, the hydrant support of one embodiment of the present invention is shown that includes a tube 26 and a flange 30. Although shown herein, the tube 26 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com