Charging member, charging device, image forming apparatus, and process cartridge

a charging device and charging device technology, applied in electrographic process apparatus, corona discharge, instruments, etc., can solve the problems of shortening the life of the photosensitive drum b>100, image failure, uneven image density and scumming, etc., to reduce the adhesiveness of soiling microparticles, minimize non-uniform charging, and reduce the effect of uneven image density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

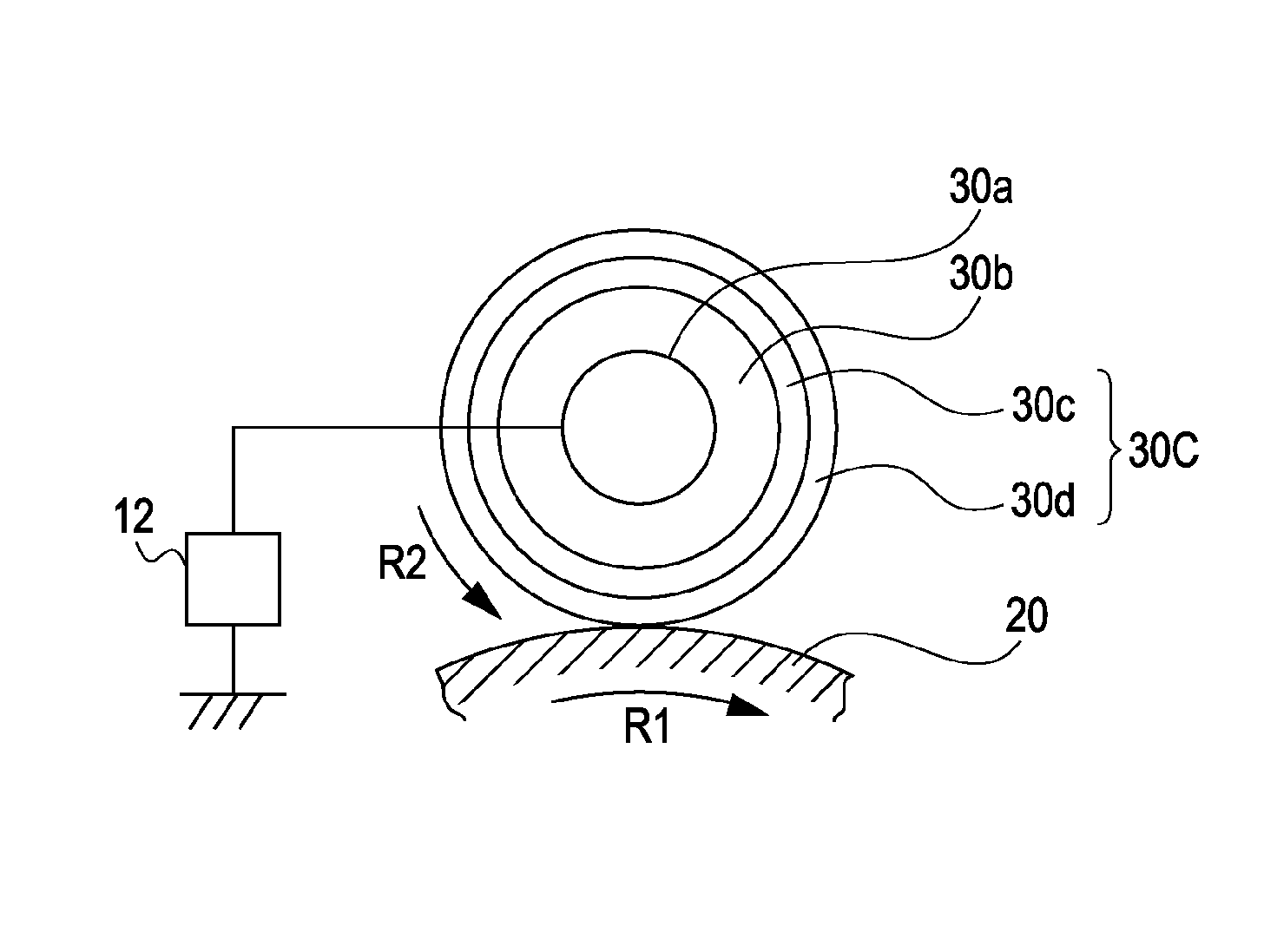

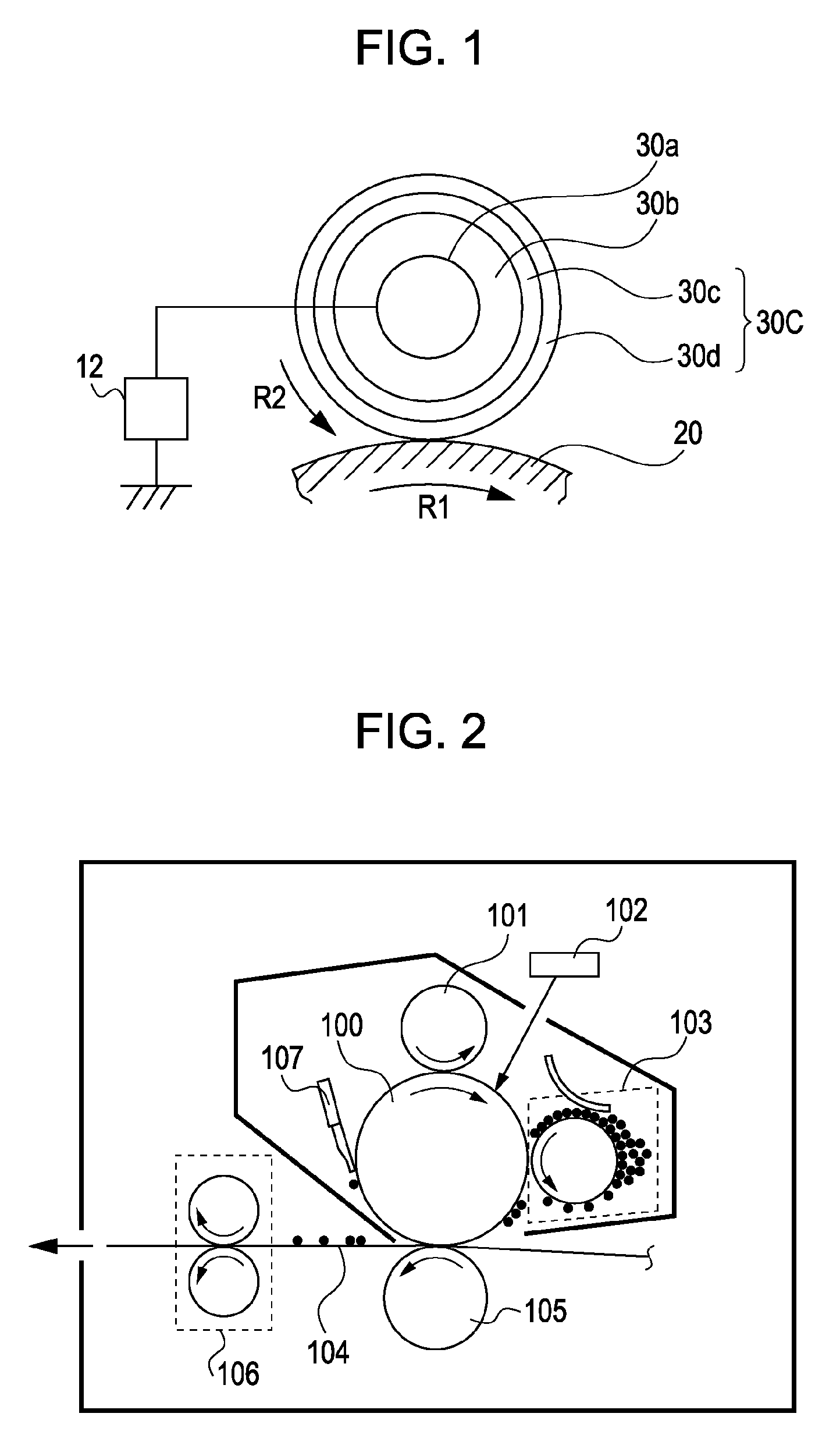

[0032]A charging member, a charging device including the charging member, a process cartridge including the charging member, and an image forming apparatus according to a first embodiment of the present invention will be described in detail below with reference to the drawings.

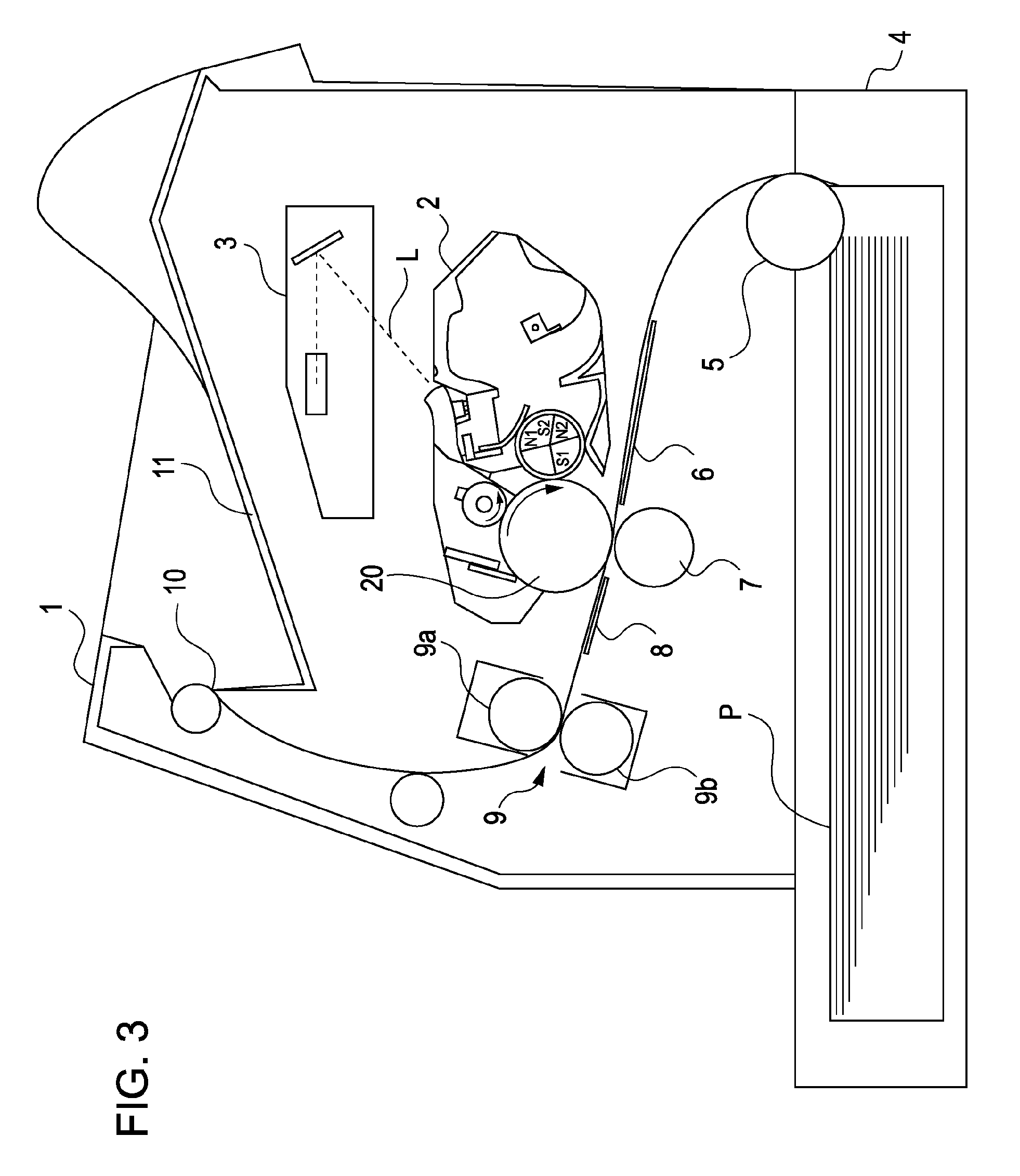

(1) Outline of Configuration and Operation of Image Forming Apparatus

[0033]FIG. 3 schematically shows a configuration of an image forming apparatus according to the first embodiment. This image forming apparatus is an electrophotographic laser beam printer in which a process cartridge is mounted removably. An external host apparatus (not shown), such as a personal computer or an image reader, is connected to the printer. The printer outputs a print according to image information input from the host apparatus to a controller (not shown). The controller exchanges signals with the host apparatus. The controller also exchanges signals with an image forming device to control an image forming sequence.

[0034]The prin...

second embodiment

[0101]A second embodiment realizes space saving by decreasing the outer diameter of a charging roller 30. Since structures of the second embodiment other than the outer diameter of the charging roller 30 and pressure springs 31 for pressing the charging roller 30 against a photosensitive drum 20 are similar to those adopted in the first embodiment, descriptions thereof are omitted.

[0102]In the second embodiment, the charging roller 30 has an outer diameter of 8 mm. Since the outer circumference of the charging roller 30 is thereby decreased, the number of soiling substances per unit area on the surface of the charging roller 30 increases.

[0103]Further, rigidity of the charging roller 30 is decreased by reducing the outer diameter of the charging roller 30. In the second embodiment, the entire longitudinal area of the charging roller 30 can be pressed against the photosensitive drum 20 with a sufficient contact pressure by setting the total pressure of the pressure springs 31 against...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap