Sheet stapler

a stapler and sheet metal technology, applied in the field of sheet metal staplers, can solve the problems of cumbersome work, decreased operational efficiency, and inability to perform stapling operations, and achieve the effect of eliminating cumbersome prefeeding operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

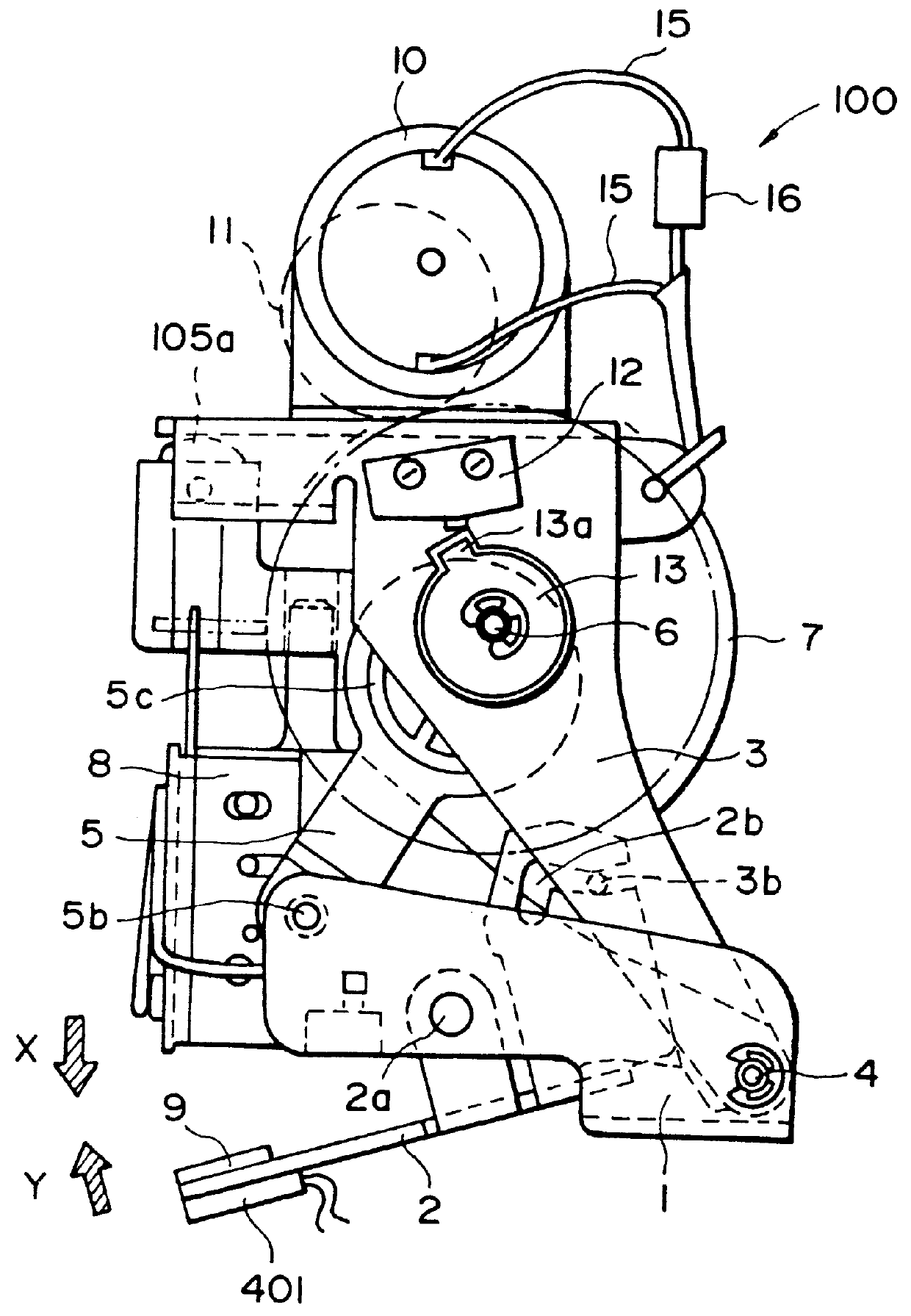

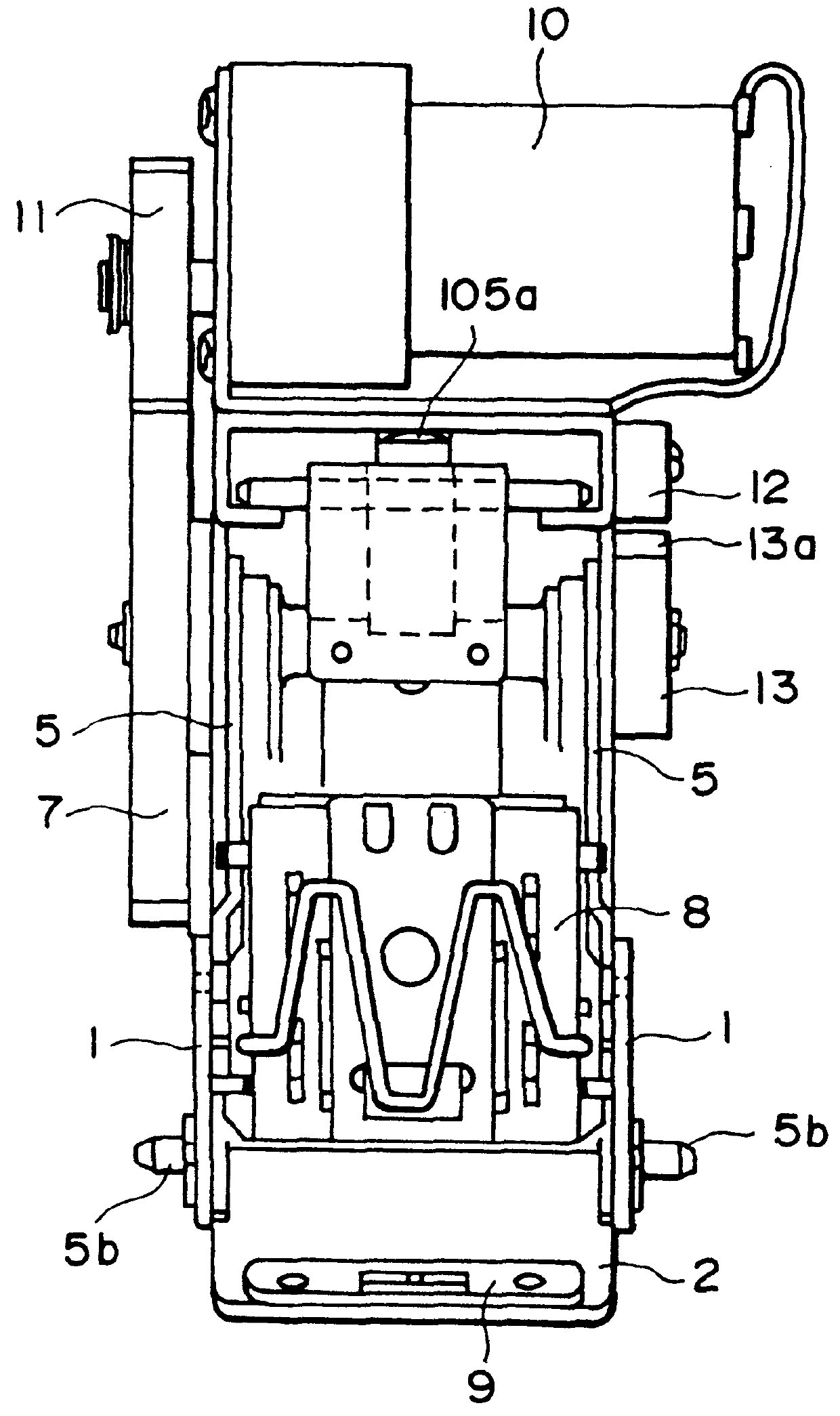

Referring first to FIGS. 2 and 3, there are shown front and side views of a stapler according to an embodiment of the present invention. As shown in FIG. 2, the stapler 100 includes a base 1 which is fixed, a lower jaw 2 rotatable about a pin 2a and an upper unit 3. At an end of the lower jaw 2, a channel-shaped cam 2b is formed and is engaged with a cramping pin 3b fixed to the upper unit 3. The upper unit 3 is swingably supported on a hinge pin 4 mounted to the base. A crank arm 5 is rotatably supported on a part of base 1 by a pin 5b adjacent an end of the crank arm 5. The other end thereof is engaged with a cam plate 5c fixedly and eccentrically mounted to a drive shaft 6. When a stapler gear 7 rotates through one full turn, the cam plate 5c rotates about the pin 6. At this time, since the base 1 is fixed, and since the distance between the pin 5b and the pin 6 is constant, the upper unit 3 rotates about the hinge pin 4 relative to the base 1. Also, a body 8 is pushed by a head ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| period of time | aaaaa | aaaaa |

| current | aaaaa | aaaaa |

| stapling speed | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com