Frictionally driven belted work vehicle

a belted work and friction drive technology, applied in the direction of conveyors, vehicle maintenance, vehicle cleaning, etc., can solve the problems of lower maximum travel speed, higher initial cost, and high noise levels, and achieve the effect of augmenting the guide apparatus, enhancing the guide apparatus, and ensuring the maintenance of the lateral bel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

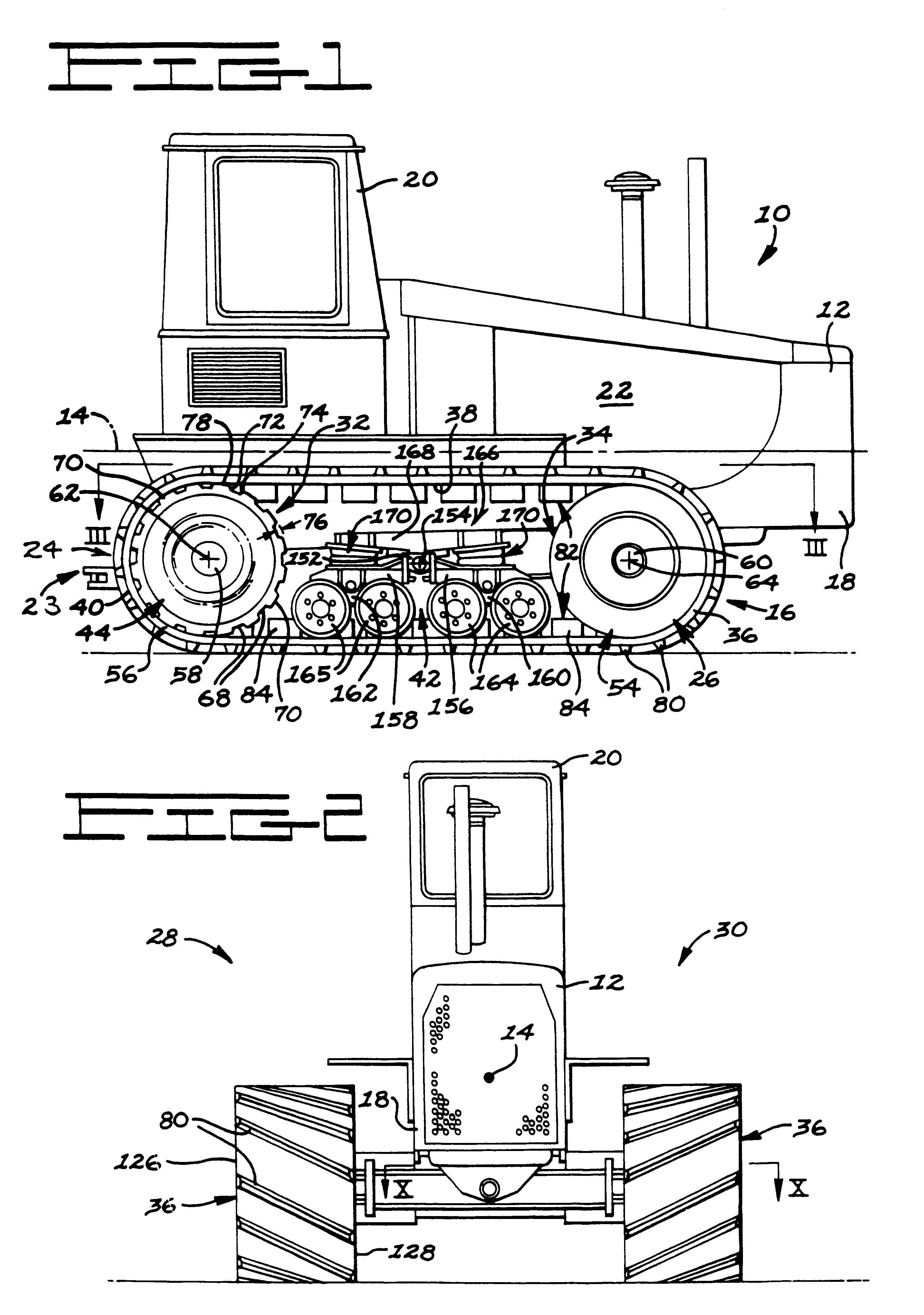

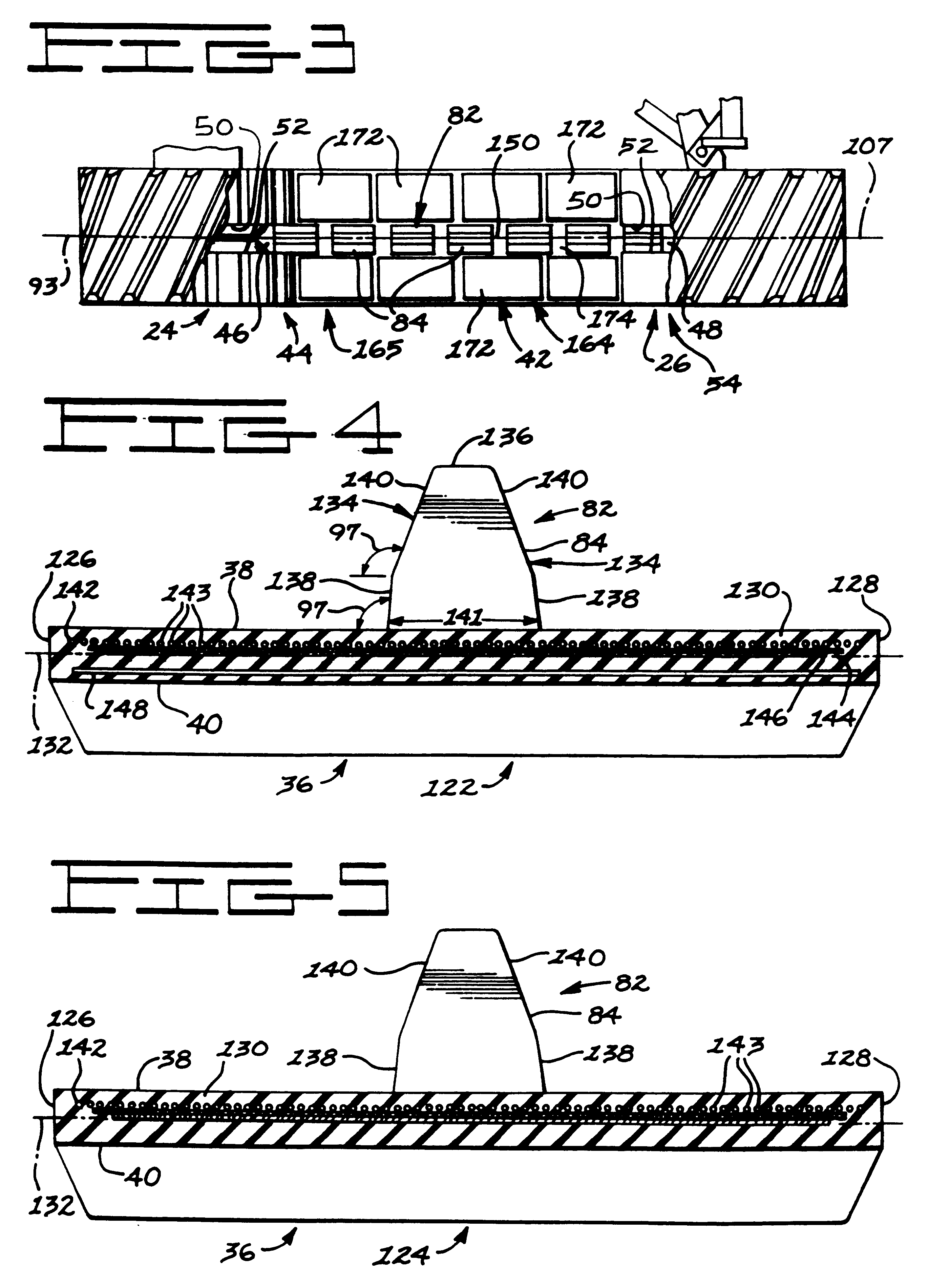

In general, the greatest problems encountered in providing a belt-over-wheel propulsion system for heavy-duty application are:

(1) Maintaining lateral registry between each belt and its entrained wheels when the utilizing vehicle is subjected to high lateral loads;

(2) Maintaining a driving relationship between the driver wheel(s) and the entraining belt; and

(3) Accommodating debris intrusion between each belt and its entrained wheels without damaging either.

Solutions to the aforementioned problems will be discussed in conjunction with the structure providing such solutions.

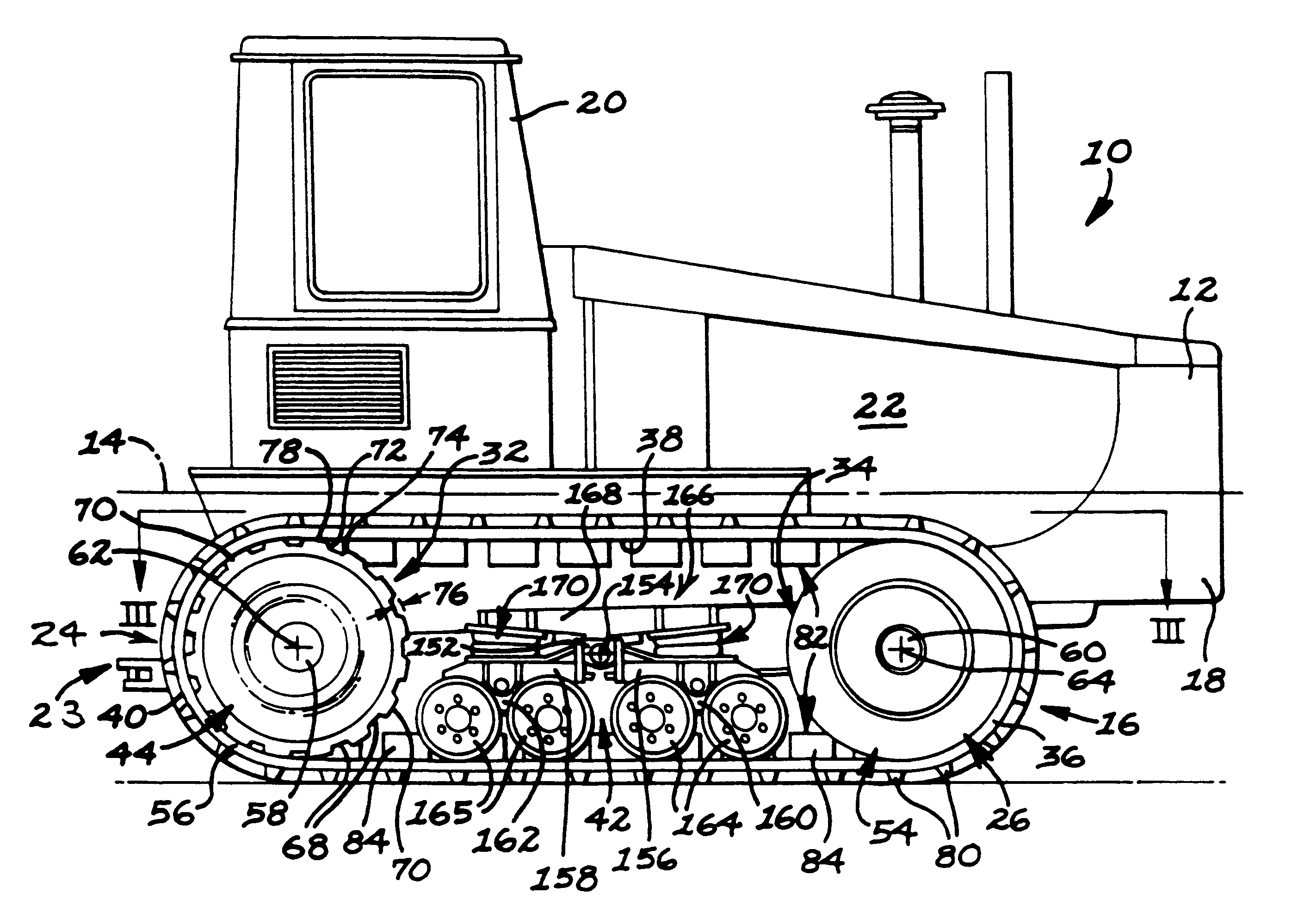

Referring now to the drawings in detail, FIG. 1 illustrates an exemplary belt laying work vehicle 10 having a chassis 12 with a longitudinal axis 14 and a propulsion system 16 which resides generally beneath and in supporting relation to a frame 18 which, together with an operator's station 20 and an engine 22, constitutes the chassis 12. A rearwardly protruding drawbar 23 is joined to the frame 18 and constitutes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com