Transparent infrared absorbing glass and method of making

a technology of infrared absorption and transparent glass, which is applied in the field of production of glass, can solve the problems of disadvantageous economic electric melting of large-scale flat glass manufacturing, undue compromising of the overall transmittance properties of glass, and achieves low infrared transmittance, high luminous transmittance, and low total iron content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example i

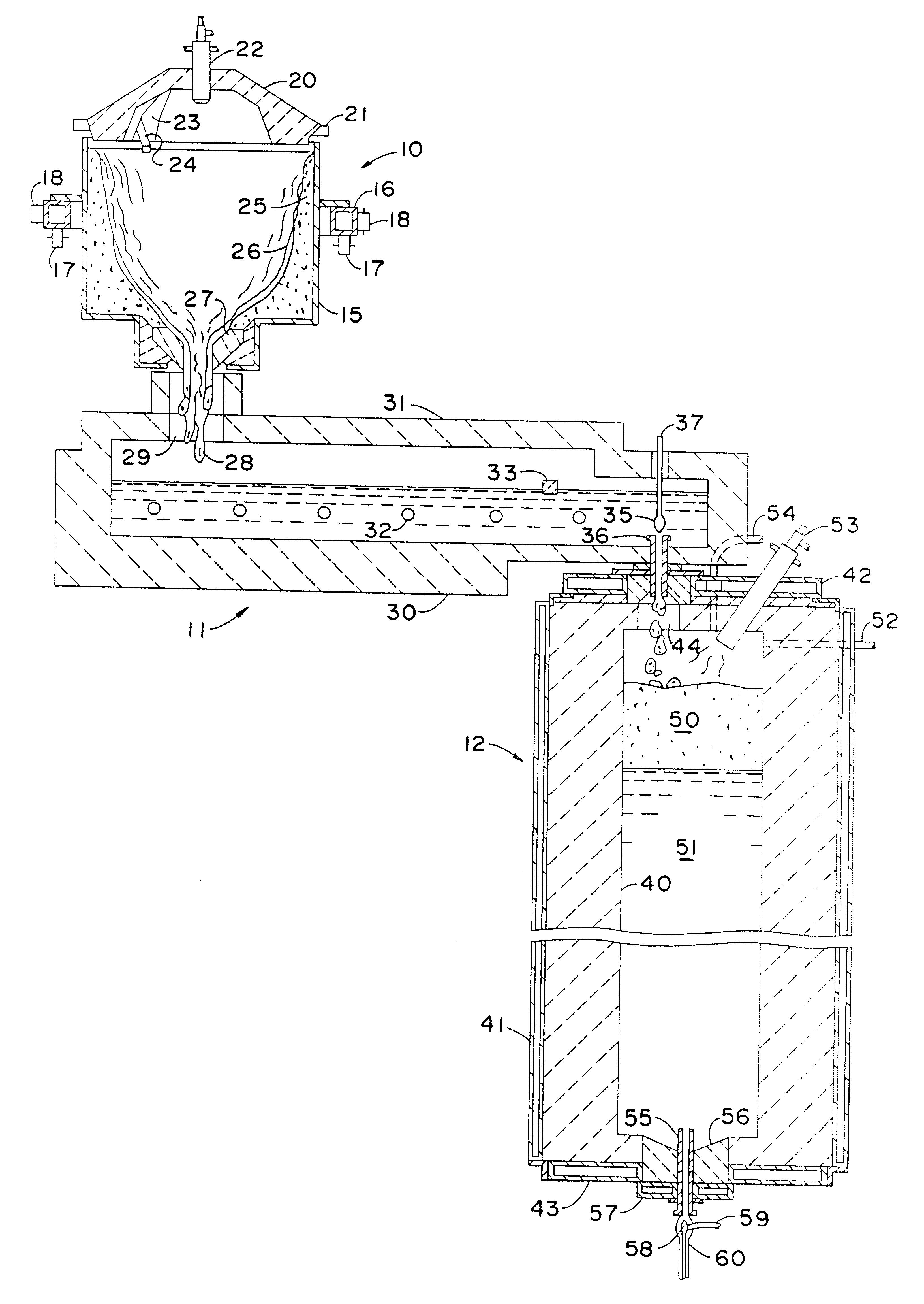

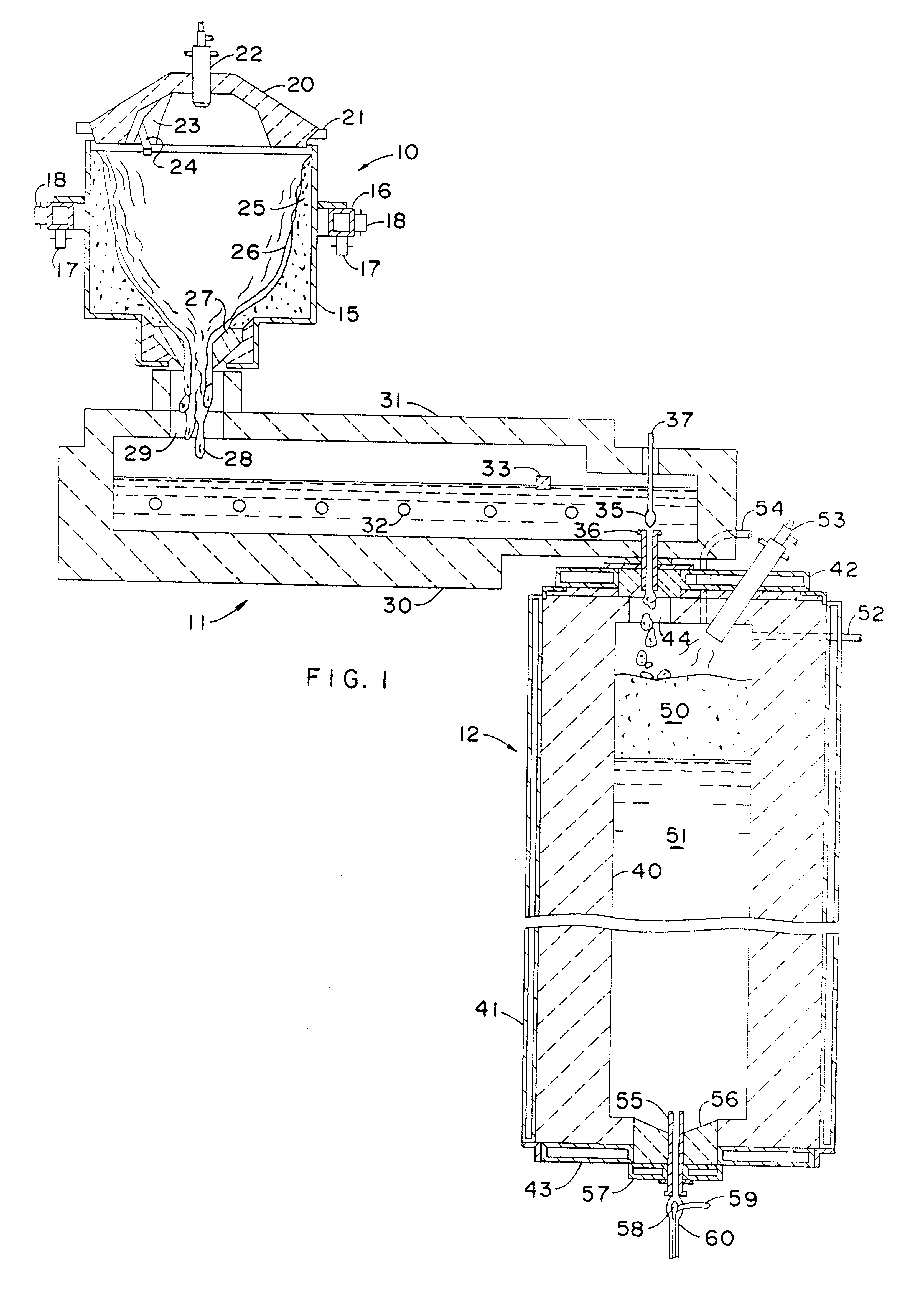

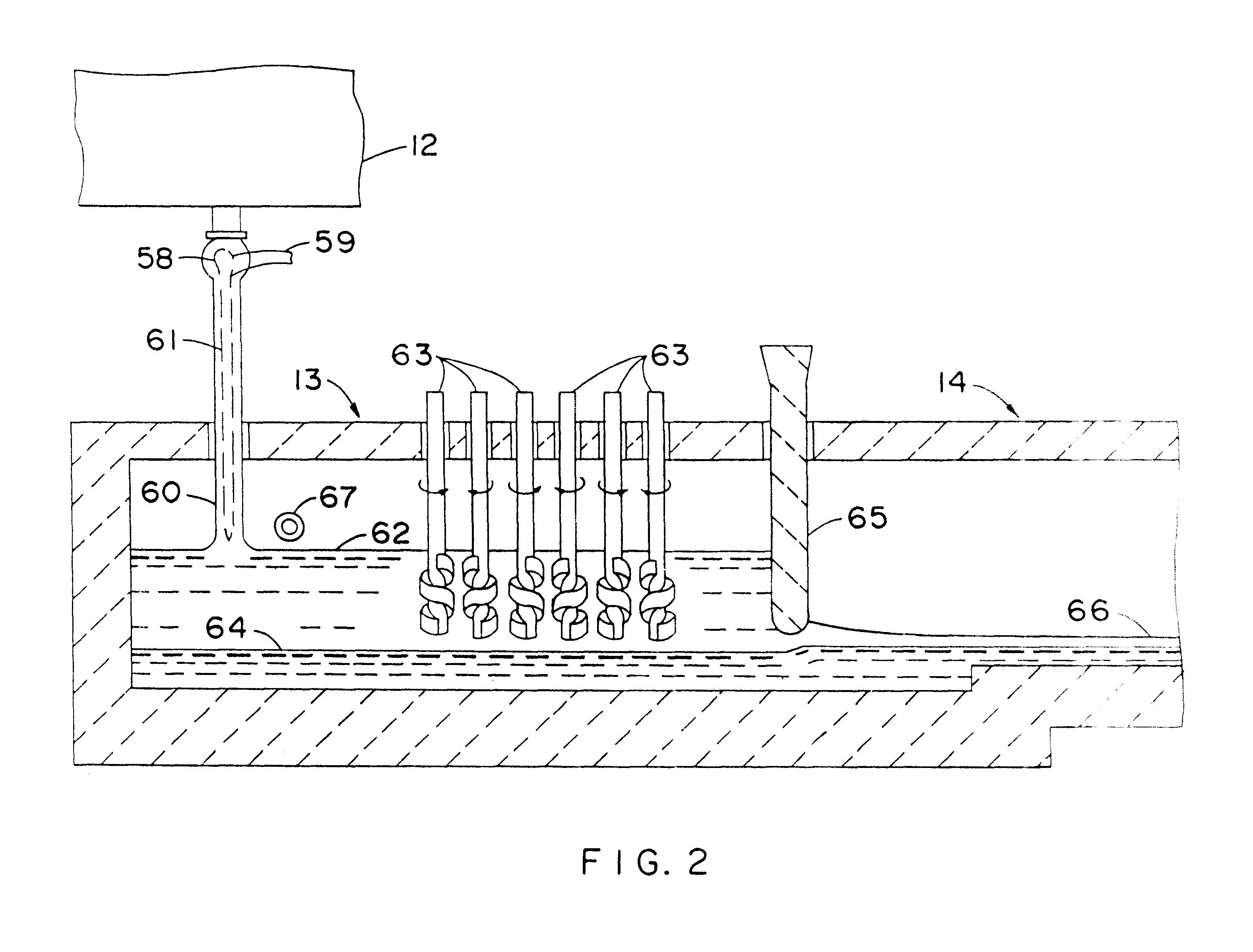

In a glass melting and refining operation essentially as shown in FIGS. 1 and 2, color additive was stirred into the refined glass at a rate of about 0.85% to 1.0% by weight of the glass. The additive was a color concentrate identified as KG-947-B by its manufacturer, Ferro Corporation, Orrville, Ohio, and contained about 40% iron in the form of magnetite (Fe.sub.3 O.sub.4). The glass had 0.118% total iron before the addition and 0.479% to 0.495% total iron after the addition. The ratio of FeO to total iron after addition ranged from 0.47 to 0.55, and SO.sub.3 content was 0.003% to 0.005%. The resulting glass in a 5 millimeter thickness exhibited LT.sub.A of 68.4% to 69.3% and infrared transmittance of 11.2% to 13.9%.

example ii

In a glass melting and refining operation essentially as shown in FIGS. 1 and 2, an iron-containing additive was included in the batch mixture in the amount of 1.9% by weight of the batch. The additive was "Melite 40" a nearly sulfur-free CaO--Al.sub.2 O.sub.3 --SiO.sub.2 slag containing about 20% by weight total iron, with about 80% of the iron in the form of FeO sold by the Calumite Company, Boca Raton, Fla. The batch mixture also included 0.025% by weight powdered coal to enhance reducing conditions during melting. Combustion burners in the liquefying stage were operated with reducing flames at a volume ratio of 1.9 parts oxygen to one part methane. The resulting glass had a total iron content of 0.449% to 0.473%, with a ratio of FeO to total iron of 55.6% to 60.6%. At a thickness of five millimeters, the glass exhibited LT.sub.A of 68.6% to 69.9% and infrared transmittance of 10.9% to 12.9%.

The above two examples disclose two additives that serve as iron sources with a relativel...

example iii

In a glass melting and refining operation as shown in FIGS. 1 and 2, color concentrates were melted in a small furnace and fed in molten form into the stirring chamber at about 2400.degree. F. (1315.degree. C.). The concentrates were KG-947-I containing about 40% by weight total iron, about 60% of that iron being in the form of FeO, and MI-380-B containing about 25% by weight CeO.sub.2, both sold by the Ferro Corporation. The iron color concentrates was added at the rate of 12 parts by weight per thousand parts by weight of base glass, and the cerium color concentrate was added at the rate of 20 parts to one thousand parts by weight. The total iron content of the glass increased from 0.082% by weight Fe.sub.2 O.sub.3 to 0.533% Fe.sub.2 O.sub.3 in the final glass composition with a ratio of FeO to total iron of 0.522. The final glass composition had 0.44% by weight CeO.sub.2 and less than 0.001% by weight SO.sub.3. The transmittance properties of a five millimeter thick sample of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com