Clutch cover assembly

a technology of clutch disc and assembly, which is applied in the direction of friction clutches, mechanical actuated clutches, and clutch disc assemblies, can solve the problems of shortening the life of the clutch disc assembly and the clutch disc assembly, and the inability to maintain the initial pressing load of the diaphragm spring 154, so as to maintain the initial pressing load correctly and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

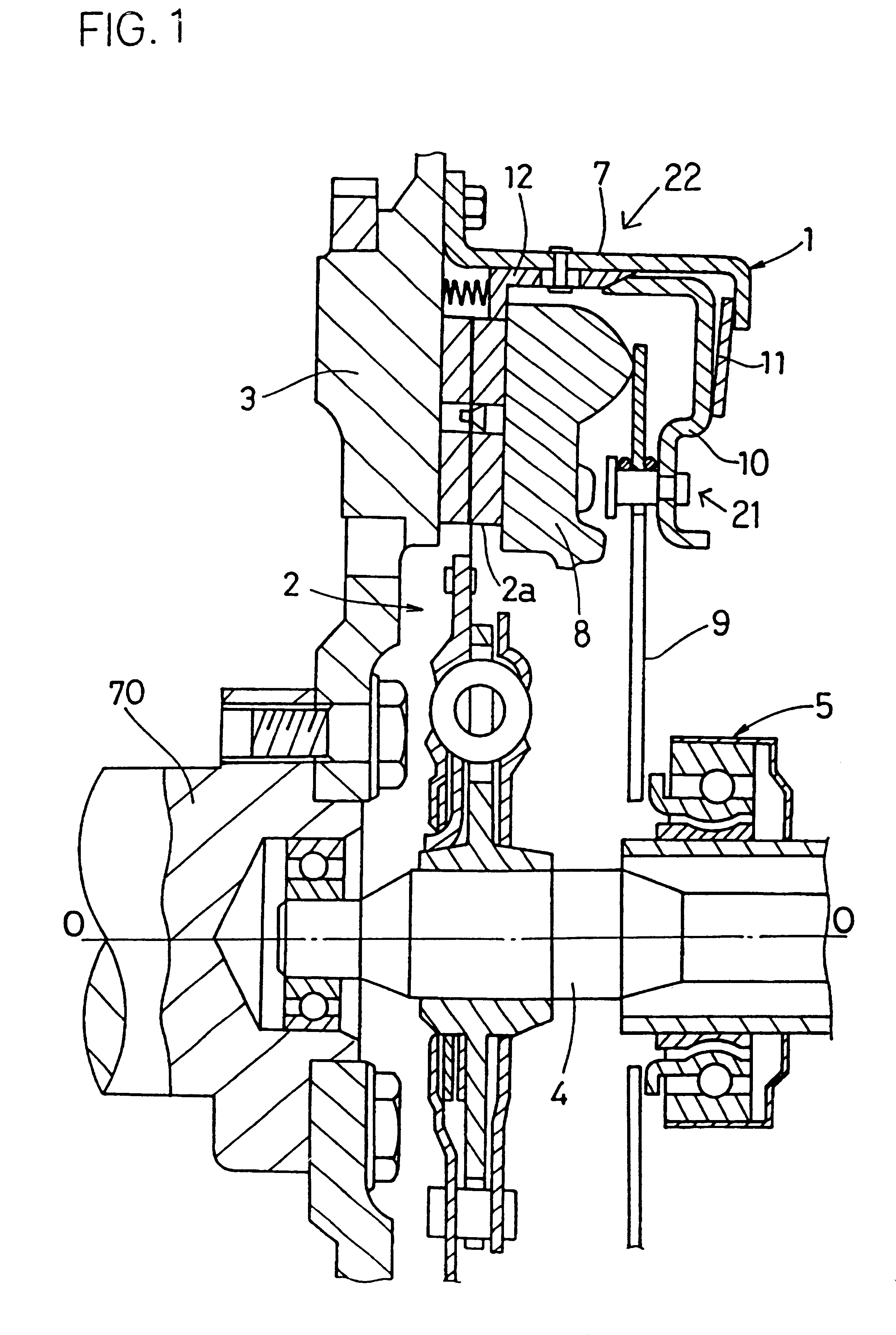

FIG. 1 shows a clutch to which the first embodiment of the present invention is applied. The clutch is principally composed of a clutch cover assembly 1 fixed to a flywheel 3, and a clutch disc assembly 2. The flywheel 3 is fixed to a crankshaft 70 of the engine. A main drive shaft 4, extending from the transmission side (right in FIG. 1), is spline-engaged with the center of the clutch disc assembly 2. A release bearing 5 of the release assembly is located around the main drive shaft 4 so as to move in the axial direction.

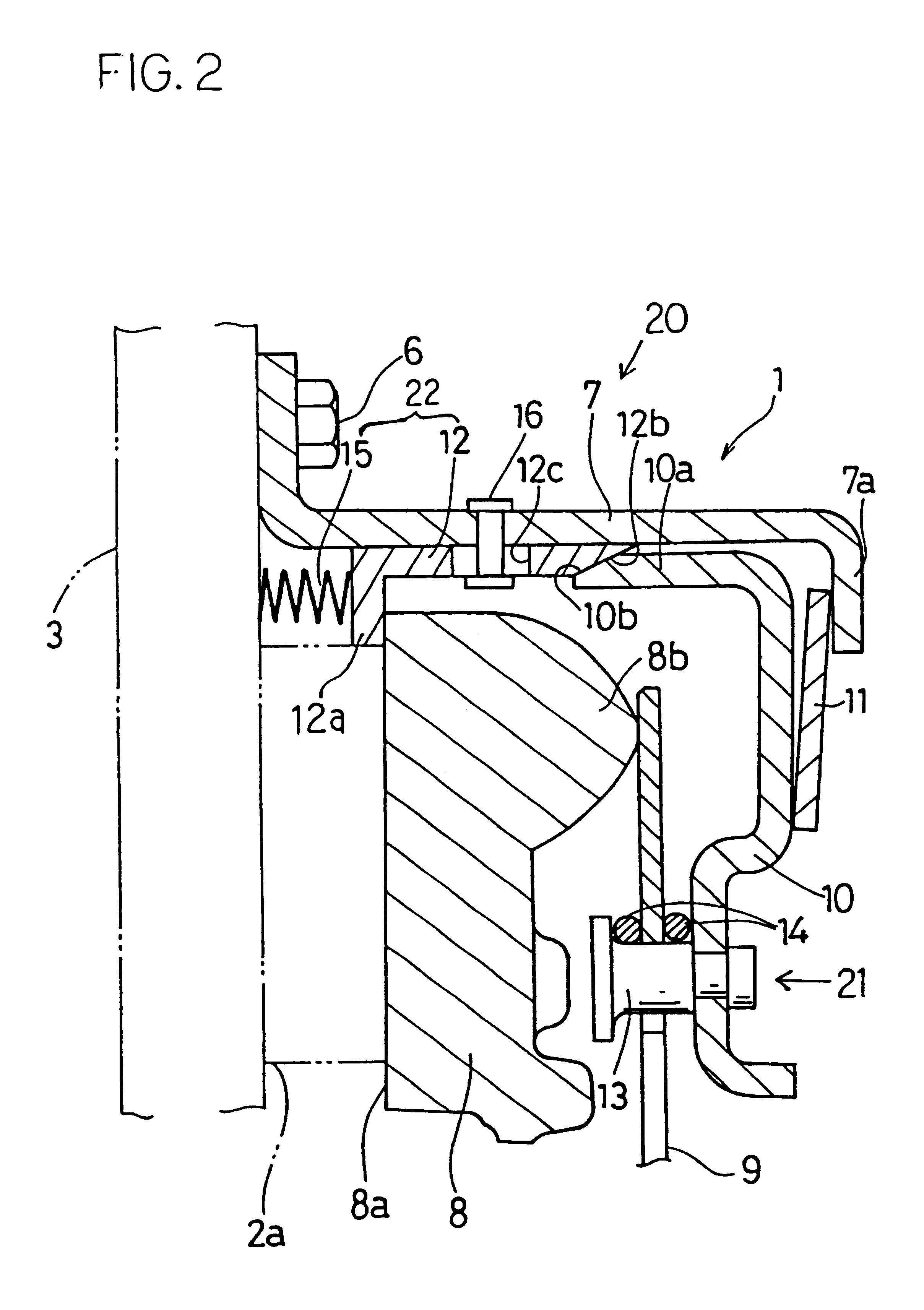

The clutch cover assembly 1 comprises, as shown in FIG. 2, a first clutch cover 7 fixed to the flywheel 3 by bolts 6, a pressure plate 8 located within the first clutch cover 7, a diaphragm spring 9 for pressing the pressure plate 8 toward the flywheel 3, a support mechanism 21 for supporting the diaphragm spring 9, and a movement regulation mechanism 20 for moving the support mechanism 21 toward the flywheel 3 according to the displacement due to wear on facings ...

second embodiment

A clutch cover assembly 31 shown in FIG. 4 is used in a push-type clutch as in the first embodiment. The clutch cover assembly 31 mainly comprises a clutch cover 37 fixed to a flywheel 33 of the engine (not shown), a pressure plate 38 located within the clutch cover 37, a diaphragm spring 39 for pressing the pressure plate 38 toward the flywheel 33, a support mechanism 41 for supporting the diaphragm spring 39, and a movement regulation mechanism 51 for moving the support mechanism 41 toward the facings 32a according to the wear amount of the facings 32a of the clutch disc assembly (not shown).

The clutch cover 37 has a disc portion with an inclined surface 37a approaching the pressure plate 38 as its goes radially outward.

The pressure plate 38 is generally annular, and is formed with a lateral pressing surface 38a for pressing the facing 32a against the flywheel 33. Formed on the opposite lateral side of the pressure plate 38 are extensions 38b that extend axially. Integrally formed...

third embodiment

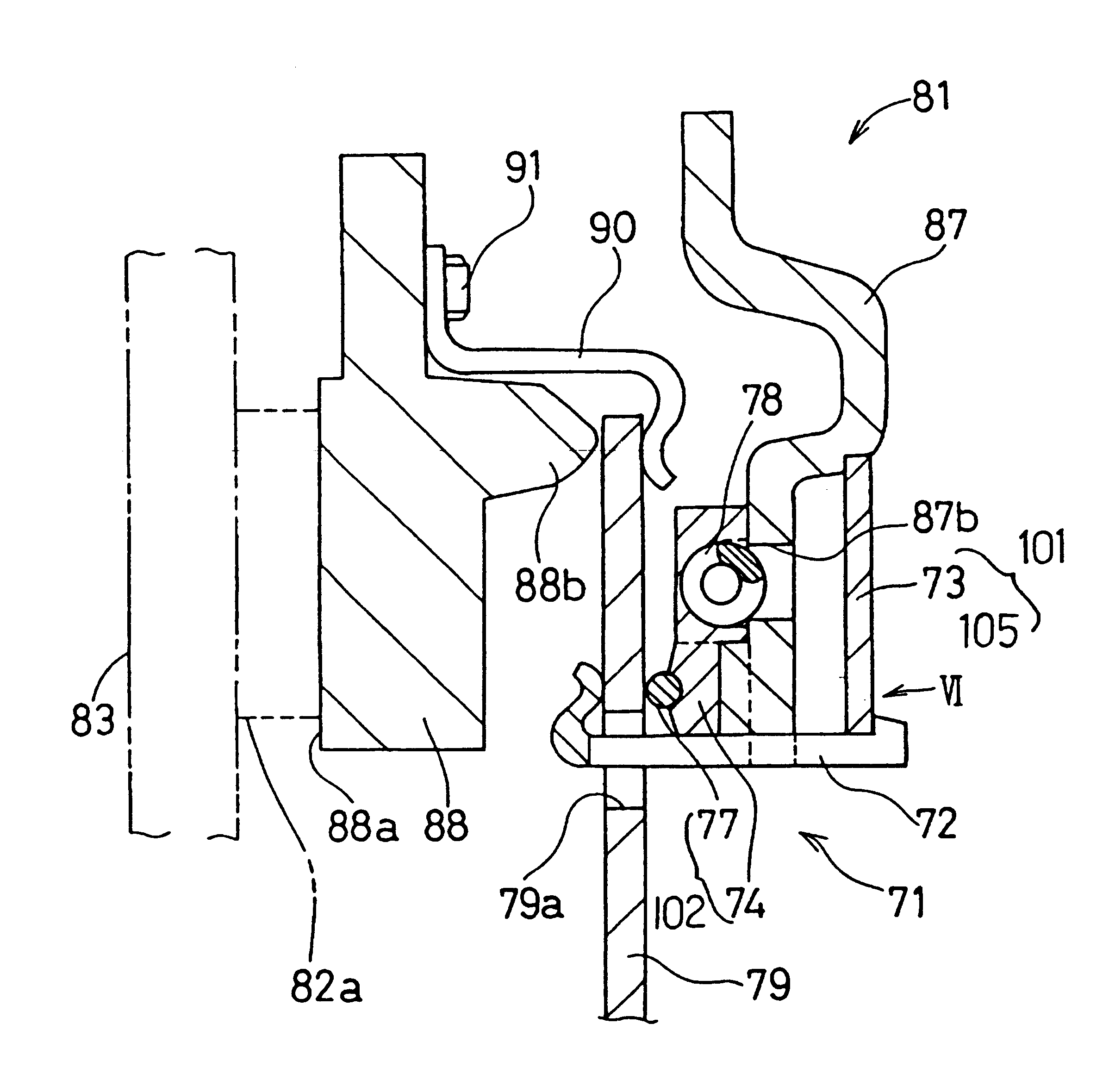

A clutch cover assembly 81 shown in FIG. 5 is employed in a push-type clutch like the first and the second embodiments, and comprises a clutch cover 87 fixed to the flywheel 83 of the engine, a pressure plate 88 located in the clutch cover 87, a diaphragm spring 79 for pressing the pressure plate 88 toward the flywheel 83, and a support mechanism 71 for supporting the diaphragm spring 79, and a movement regulation mechanism 101 for moving the support mechanism 71 toward the facings 82a according to wear of the facings 82a of a clutch disc assembly (not shown).

The pressure plate 88 is generally annular and is provided with a pressing surface 88a for clamping the facings 82a of the clutch disc assembly between the flywheel 83 and itself. The pressure plate 88 is formed with annular projections 88b projecting in the axial direction on the diaphragm spring 79 side. The pressure plate 88 is fixed to the clutch cover 87 through strap plates (not shown) so as to be movable in the axial dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com