Stackable pallet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

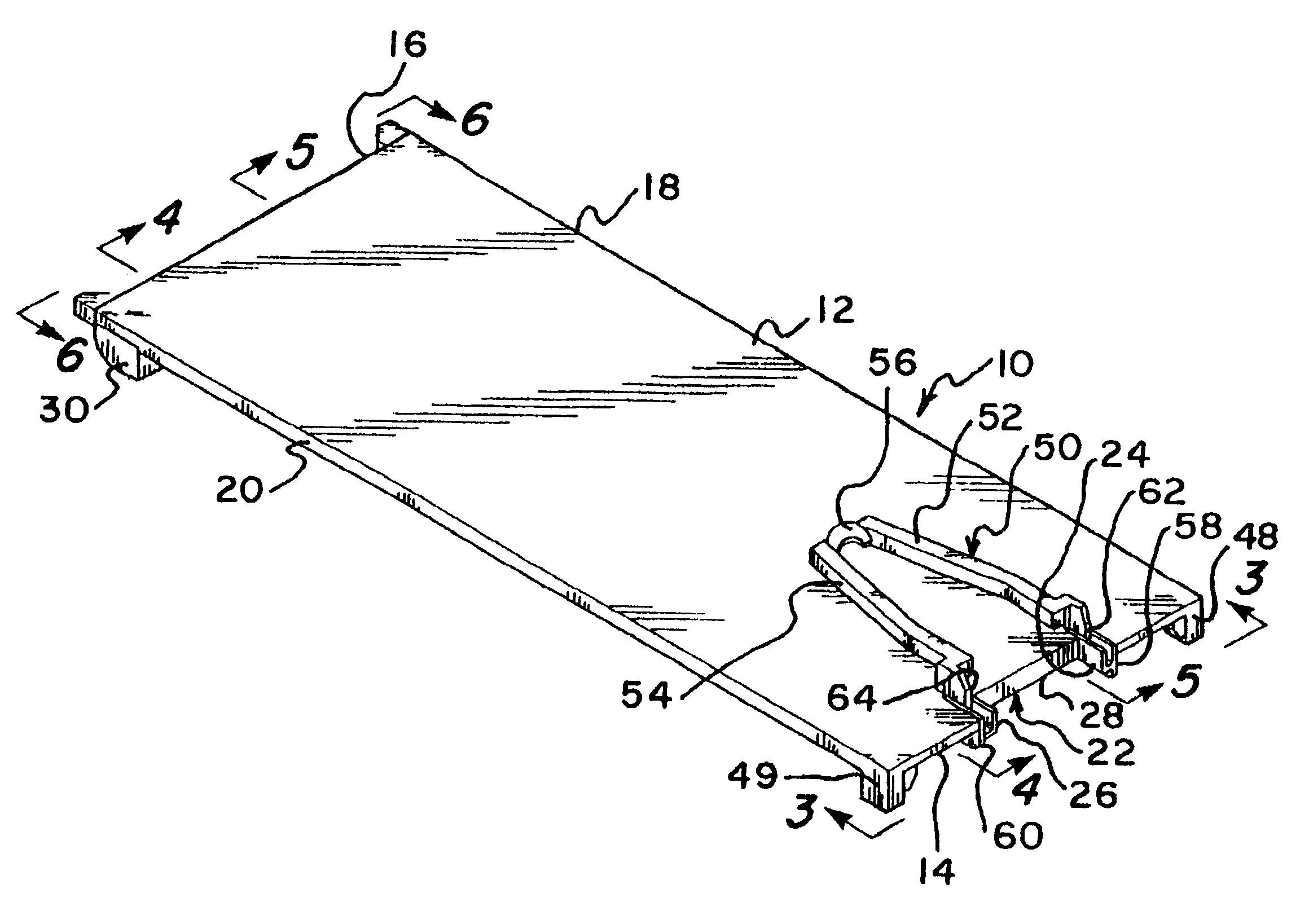

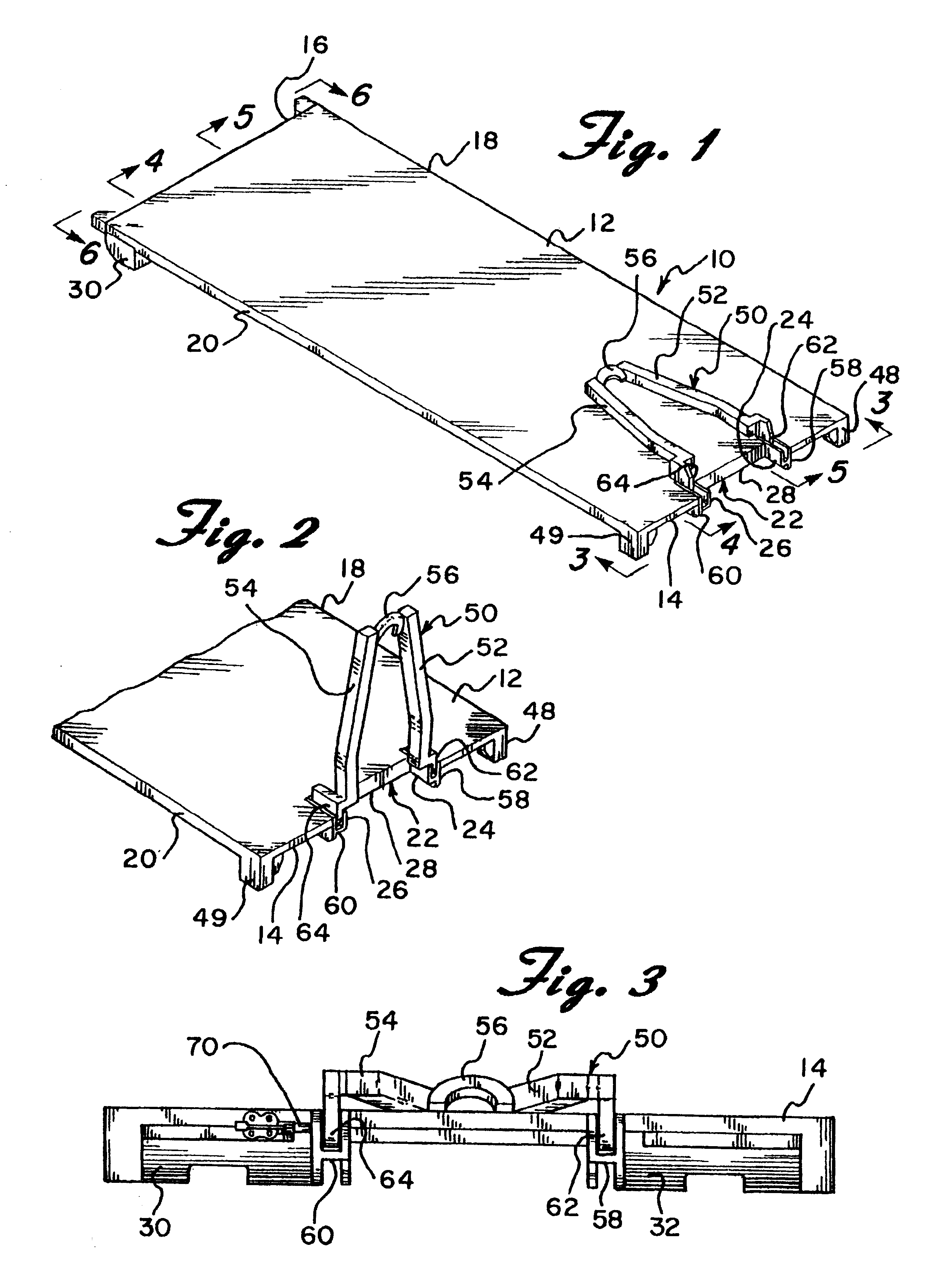

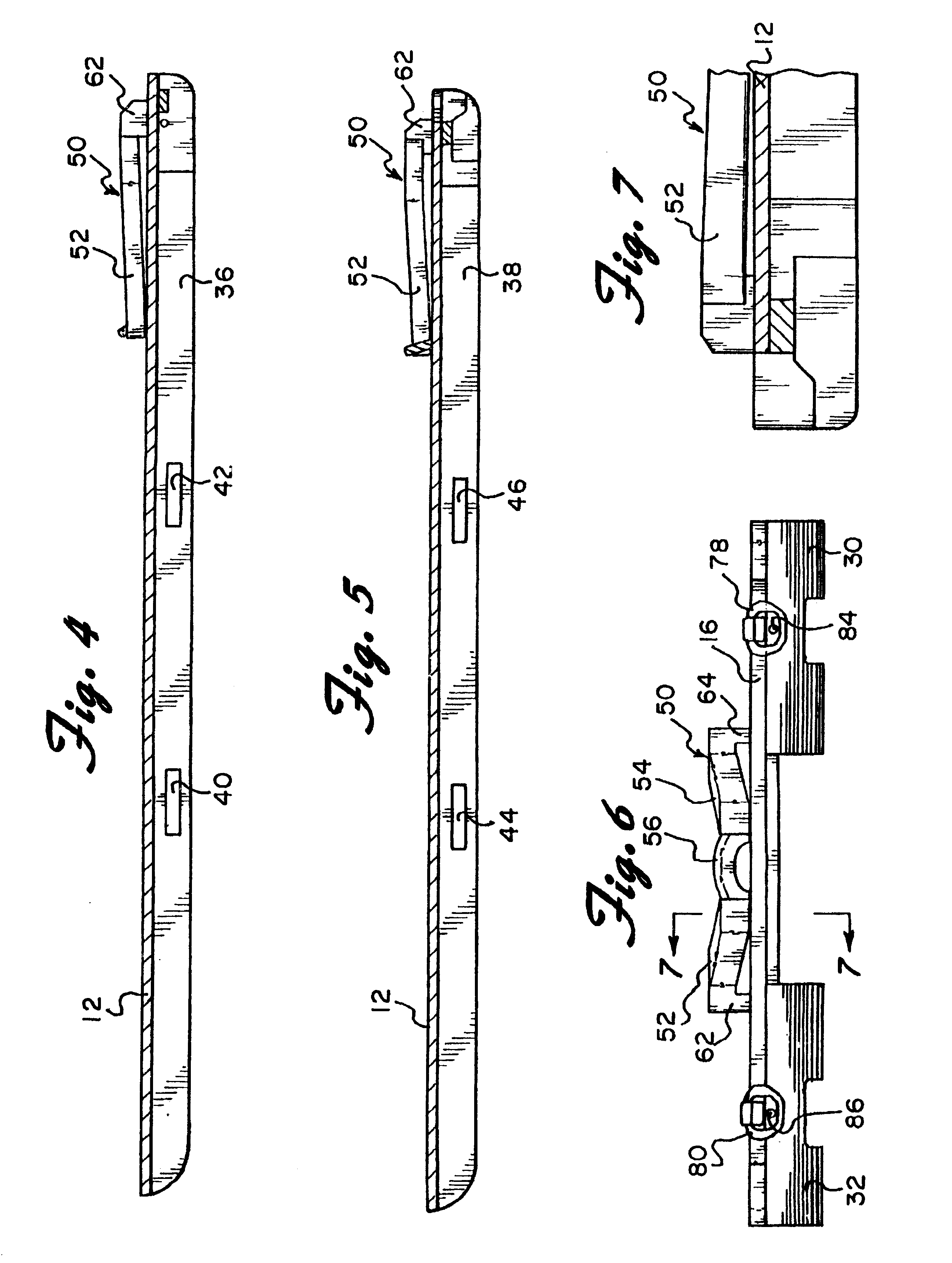

Referring now to the drawings in detail wherein like reference numerals have been used throughout the various figures to designate like elements, there is shown in FIG. 1 a stackable pallet constructed in accordance with the principles of the present invention and designated generally as 10.

The stackable pallet 10 includes a rectangular planar base member 12 which, as can clearly be seen in the figures, has a width and a length. The base member has a first end 14, a second end 16, and two opposing sides 18 and 20. Extending into the first end 14 of the base member 12 is a recess 22. The recess 22 is defined by two side edges 24 and 26 and a transverse edge 28. The base member 12 is preferably about 585 cm long, 230 cm wide, and 12.5 cm high.

Slider pads in the form of smooth curved segments 30 and 32 extend downwardly from the bottom of the base member 12 adjacent the second end 16 thereof (FIG. 6). Each slider pad is positioned adjacent a different one of the sides 18 and 20 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com