Impact sound insulation

a sound insulation and impact technology, applied in the field of sound insulation materials, can solve the problems of increasing the thickness of the material, affecting the sound insulation effect, so as to reduce the height required and prevent damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

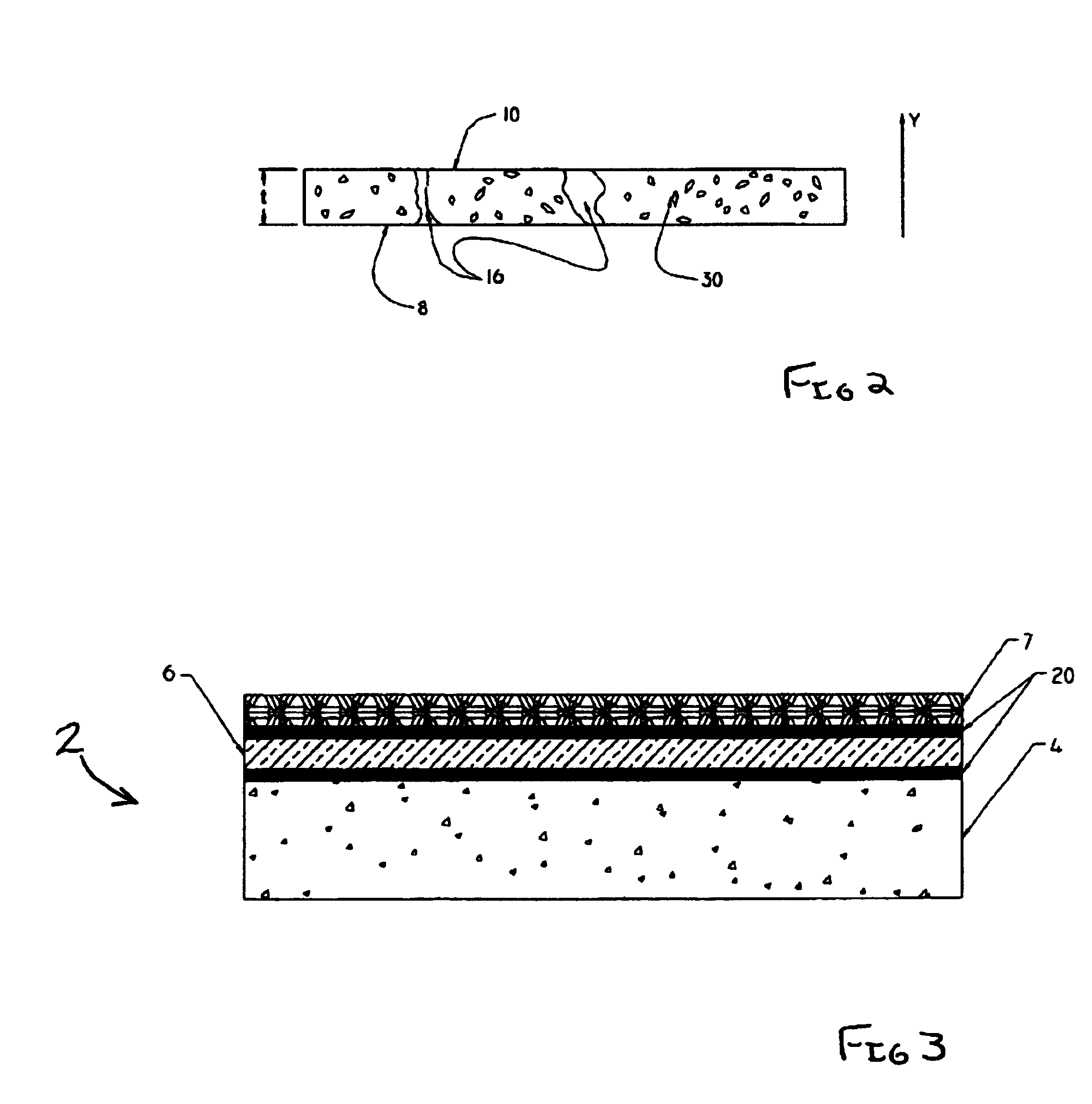

[0012]Referring to FIG. 3, a flooring system 2 according to the present invention is shown. The flooring system 2 has a base or subfloor 4. The subfloor 4 is an integral part of the building or structure and can be in the form of a concrete slab, plywood floor, or any other known material commonly used in the building industry. Positioned above the subfloor is a sound absorbing substrate 6 and decorative top layer 7. The sound absorbing substrate 6 may be affixed to the subfloor 4 and / or the decorative top layer 7 by means of mastic or glue layers 20. As the use of mastics or glues are well known in the industry, a further explanation of the glue will not be provided.

[0013]The decorative top layer may be wood, linoleum, ceramic tile, carpet, or any other known flooring. Individual components of the decorative top layer 7 are positioned in place and secured to each other by frictional engagement, glue, grout, or other conventional means. As decorative flooring is commonly used, a fur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com