Electrical clamp connector and connecting terminal

a technology of connecting terminals and clamp connectors, which is applied in the direction of coupling device connections, contact member penetrating/cutting insulation/cable strands, contact member manufacturing, etc., can solve the problems of large space occupation of known terminals of this type, and achieve the effect of cost-effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

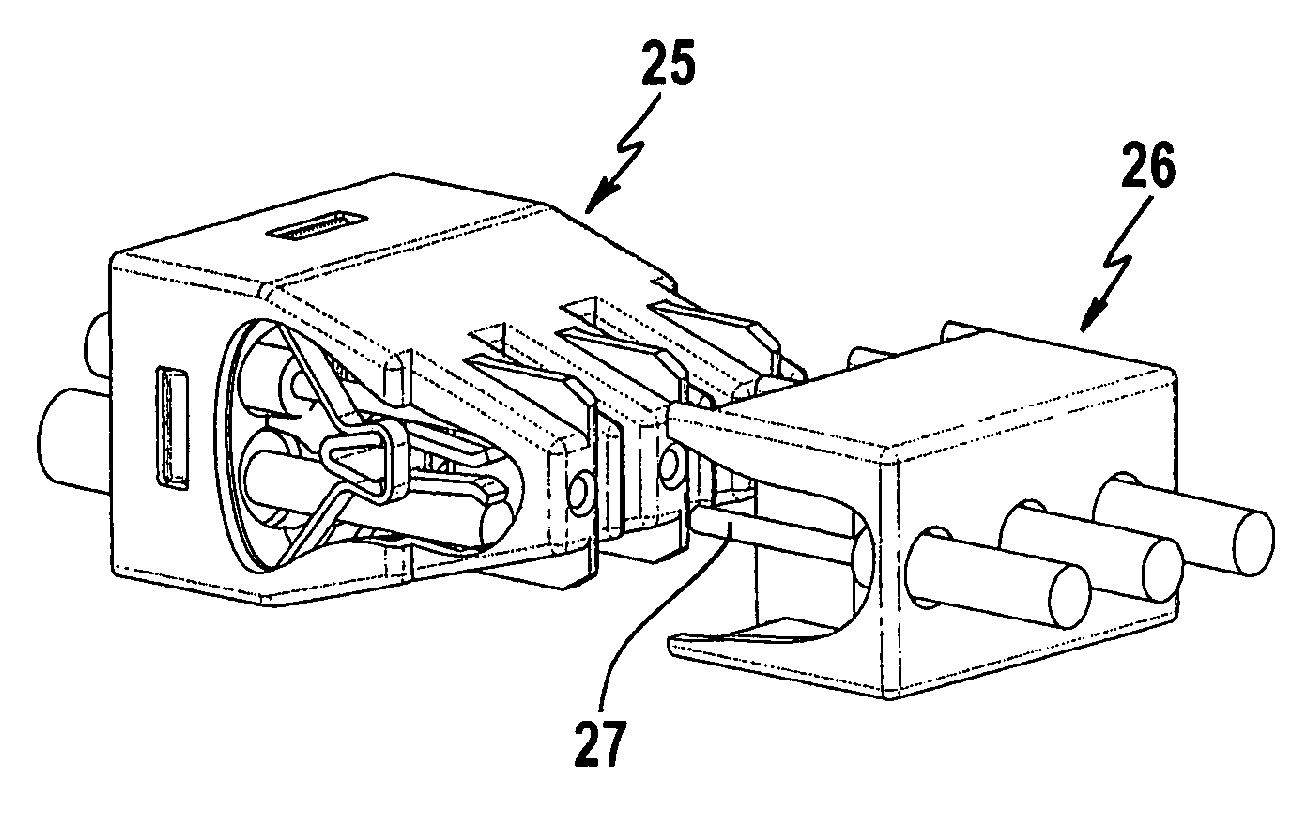

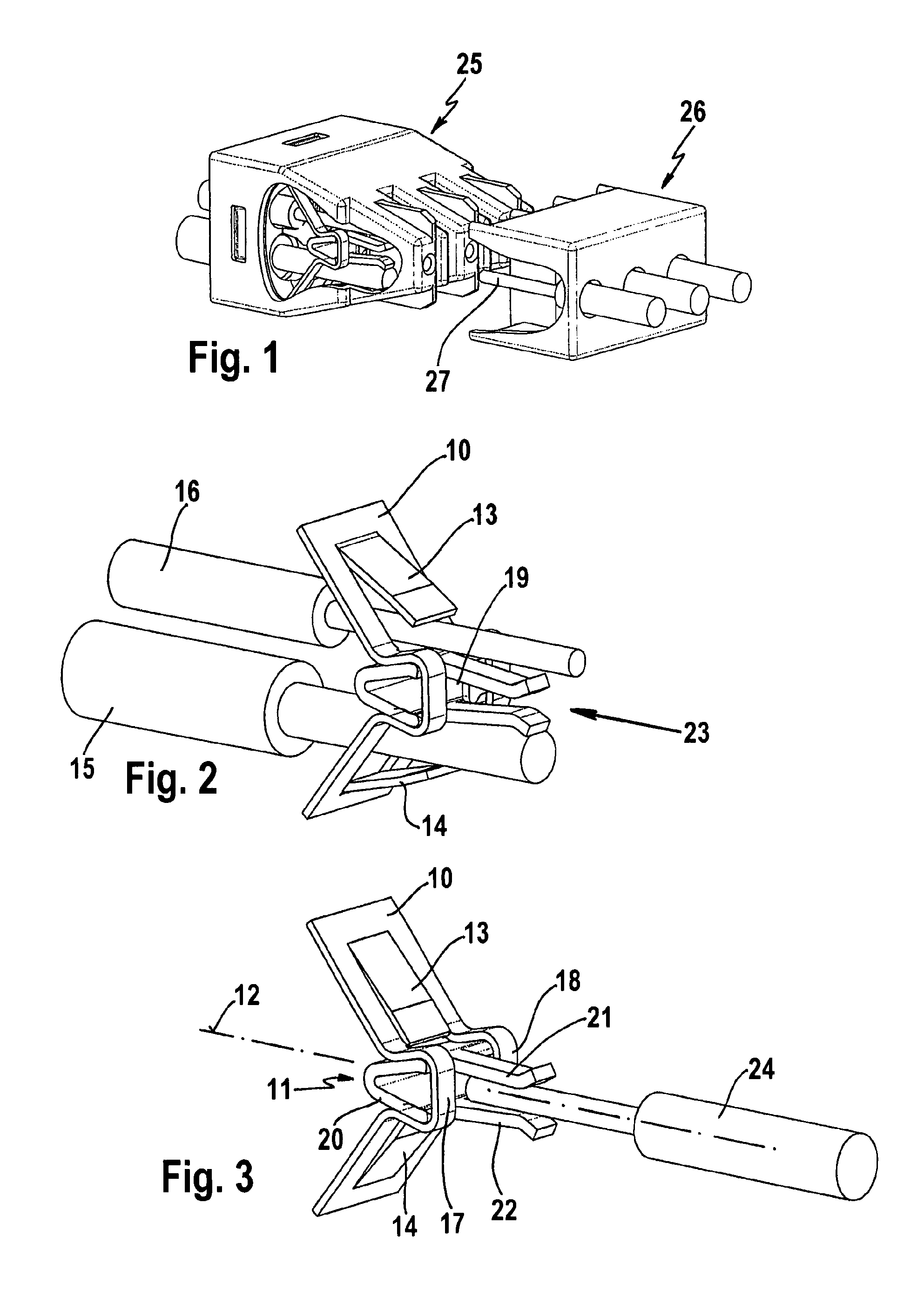

[0014]FIGS. 2 and 3 show a one-pole clamp connector and connecting terminal, consisting of one piece of spring steel sheet 10 and a busbar rod 11.

[0015]From the piece of spring steel sheet 10, a pair of leaf springs 13, 14 are cut out mirror-symmetrically to the central plane 12 (see FIG. 3) and, together with the busbar rod 11, each forms a terminal site for connecting the electrical conductors 15 and 16. The electrical conductors may have different conductor cross sections, because the cut-out leaf spring tongues 13 and 14 work independently of each other and are joined together only via the two outer crosspieces 17 and 18 (see FIG. 3) of the spring steel sheet. The crosspieces 17 and 18, in turn, are locked together with the busbar rod 11 in fixed position.

[0016]The busbar rod 11 is constructed with a V shape in cross section and has a spine 20 (in the embodiment example depicted, this is the V-shaped bent part of the busbar rod) and two cross projections 21 and 22 projecting awa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com