Preparation of hydrophilic pressure sensitive adhesives having optimized adhesive properties

a technology of hydrophilic pressure sensitive adhesives and compositions, which is applied in the field of preparation of hydrophilic pressure sensitive adhesive compositions with optimized adhesive properties, can solve the problems of loss of adhesion to hydrated substrates, difficulty in combining diverse requirements in a single system, and normal tacky tacky pressure-sensitive adhesives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

examples 1-16

Preparation of PSA Matrices by Blending PVP and PEG400: Effects of Composition, Hydration and the Thickness of Adhesive Layer

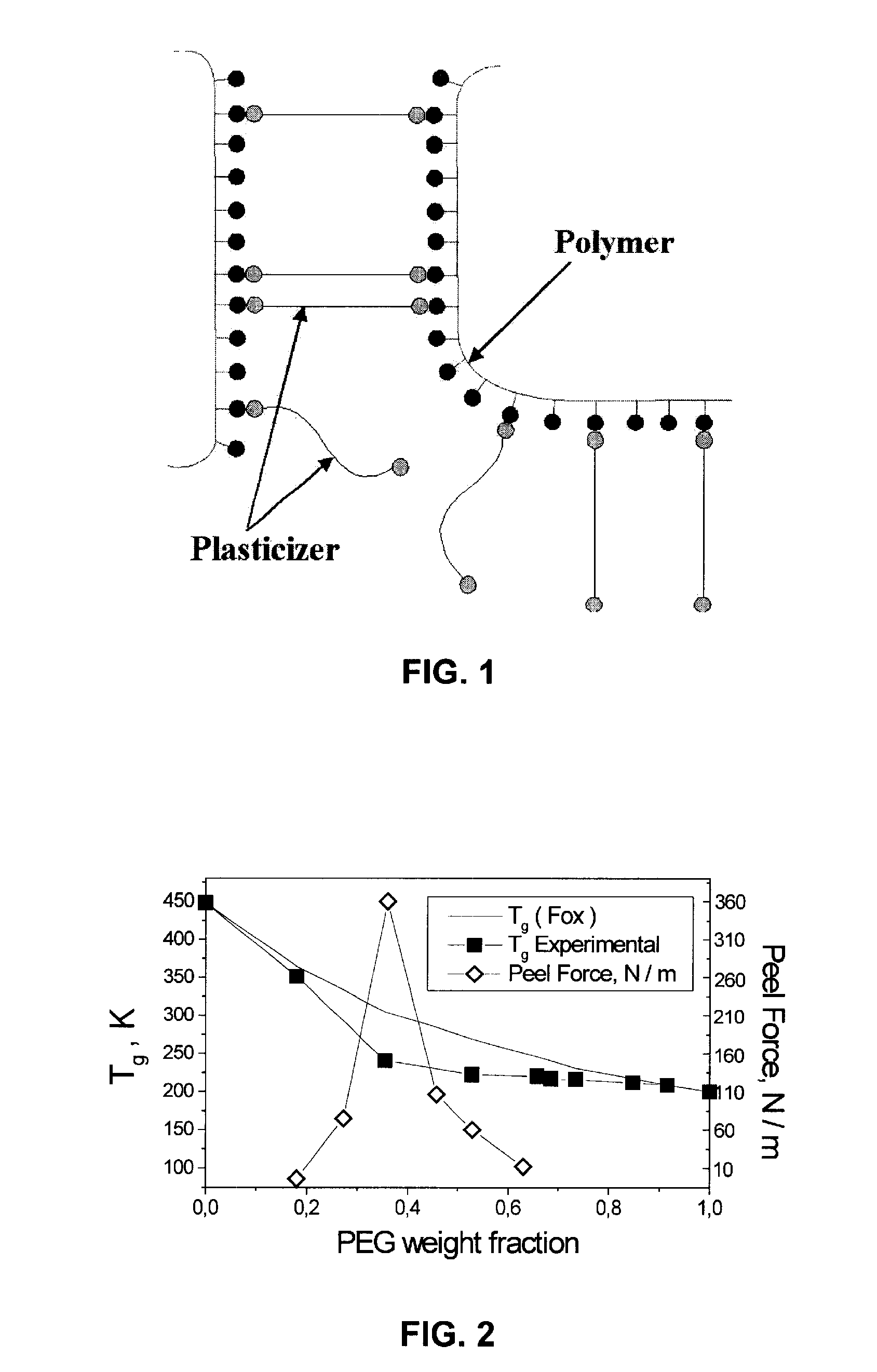

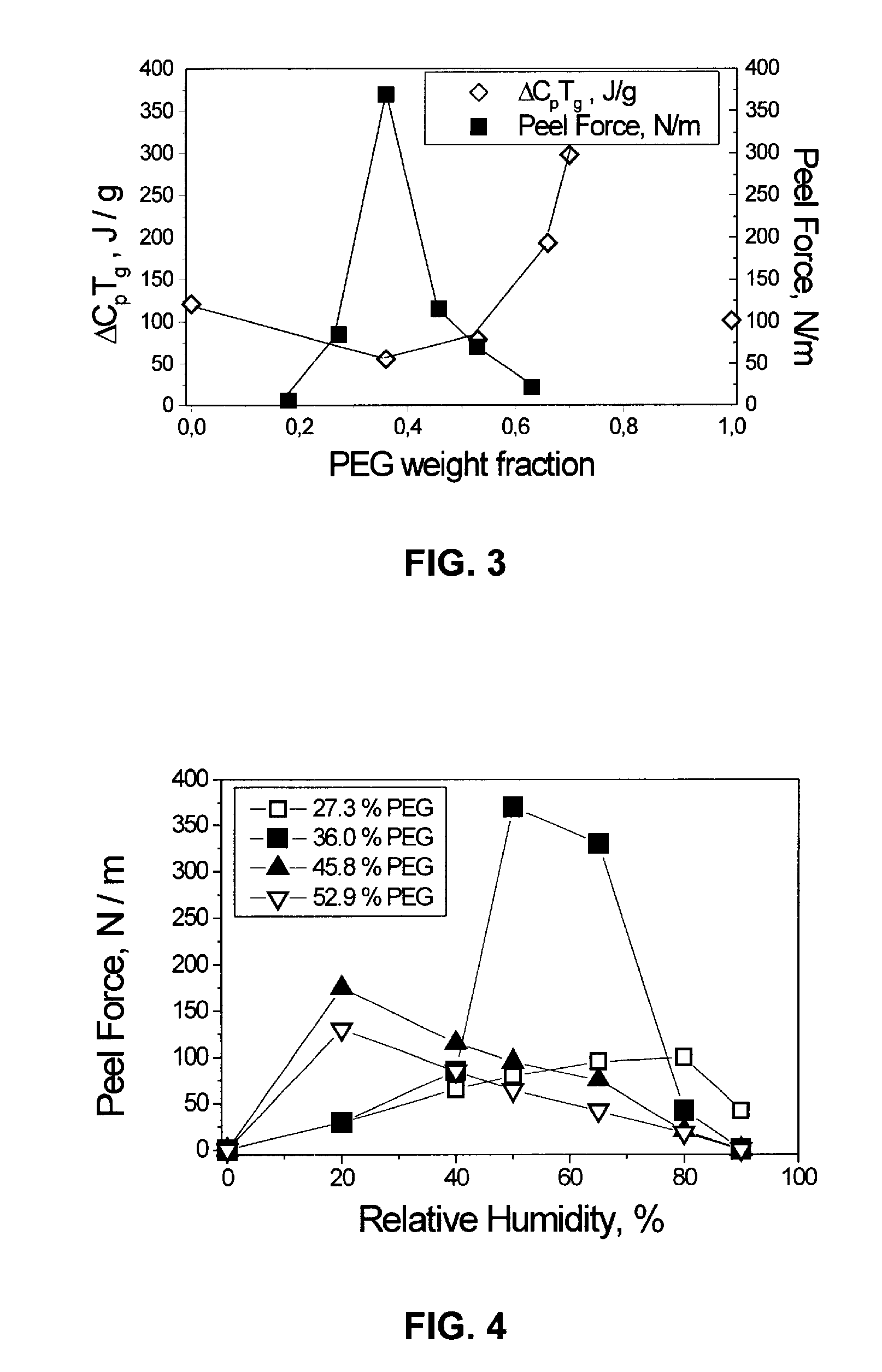

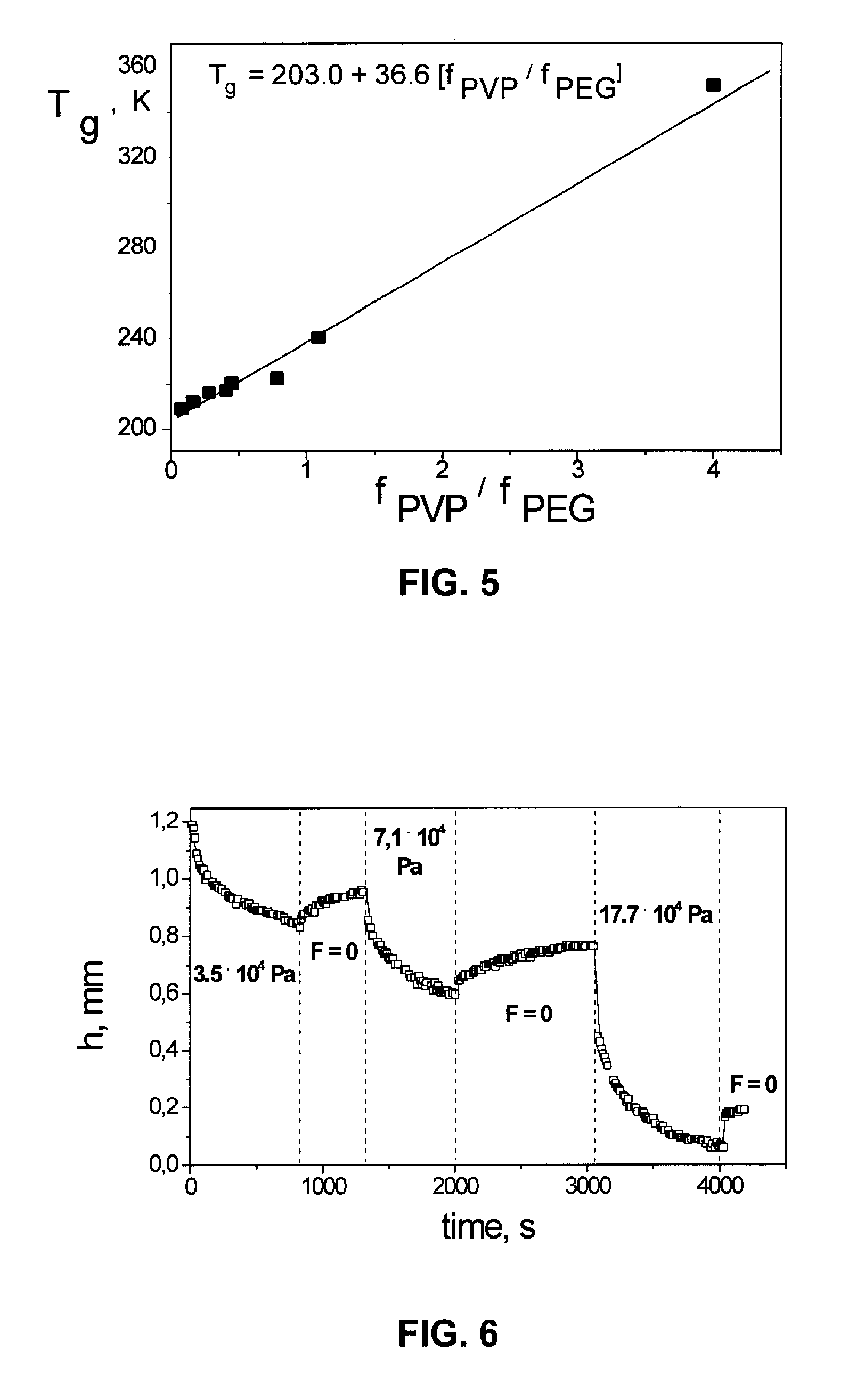

[0121]Adhesive films of 250-300 μm in thickness were prepared by dissolving hydrophilic polymers and PEG (Mw=400) in a common solvent (ethyl alcohol) followed by casting the solution on a backing film and drying. Unsupported PVP-PEG hydrogels were obtained by casting the relevant solutions onto release liner followed by drying at ambient temperature.

[0122]Adhesive joint strength of the adhesive hydrogels to standard polyethylene (PE) film of 100 m in thickness was evaluated by a 180° peel test with an Instron 1221 Tensile Strength Tester at the peeling rate of 10 mm / min. A low-density PE film, crystallinity 45%, contact angle 105°, surface energy 28.5 mJ / m2, was employed as a standard substrate. The adhesives were saturated with water by equilibrating in dessicators with a controlled pressure of water vapor of 50% at ambient temperature for 6-7 days. The time ...

examples 17-47

Preparation of PSA Matrices by Blending PVP with Different Short-chain Plasticizers. Effects of Composition, and the Relation of Adhesion to Phase State

[0130]Using the preparation procedure and evaluation tests described in Example 1, the samples of PVP K-90 blends with various plasticizers were obtained and tested at 50% RH and ambient temperature. The results are set forth in the Table 3. The tacky blends can be obtained by mixing PVP with hydroxyl-terminated (Examples 17-41) or carboxyl terminated (Examples 42-47) short-chain plasticizers. Short-chain plasticizers include: ethylene glycol (Examples 17-19) and its polymers (PEG), ranging in molecular weight from 200 to 600 g / mol (Examples 20-23); low molecular weight 1,3- and 1,2-propylene glycol (PG) (Examples 24, 25); and alkane diols from propane diol up to pentane diols (PD) and hexane diol (HD) inclusive (Examples 27-39). Polypropylene glycol (PPG) has been found to be a good plasticizer for PVP, but does not develop any adhe...

examples 48-64

PSA Compositions Prepared by Mixing Different Hydrophilic Polymers with Complementary Short-chain Plasticizers

[0131]These examples demonstrate that not only PVP but a range of different hydrophilic polymers become tacky upon mixture with short-chain plasticizers bearing complementary reactive groups at the chain ends. Suitable hydrophilic polymers include poly(N-vinyl amides) such as PVP (Examples 1-47), poly(N-vinyl caprolactam) (PVCap) (Examples 48-52) and poly(N-vinyl acetamide) (PVAA, Example 53), poly(N-alkyl acrylamides), exemplified by poly(N-isopropyl acrylamide) (PNIPAM, Example 54), polymethacrylic and polyacrylic acid (PMA, PAA, Examples 55-60), and the copolymers thereof exemplified in the Table 4 (Luviscols VAP®, commercially available from BASF; Examples 61-64). Luviscol VAP 37 is a copolymer of vinylpyrrolidone (VP, 30%) with 70% vinylacetate (VA). Luviscol VAP 73 contains 70% of VP and 30% of VA.

[0132]Among the polymers in Table 4, the best performance properties we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tg | aaaaa | aaaaa |

| melting temperature | aaaaa | aaaaa |

| melting temperature Tm | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap