Method for producing large-sized blank of wrought magnesium alloys

A technology for deformed magnesium alloys and large parts is applied in the field of preparing magnesium alloy billets, the diameter of which is larger than 300mm, and can solve the problems of coarse grains, high difficulty, and increased alloy solidification shrinkage. Economical and practical, reducing the tendency to crack, reducing the effect of thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] The implementation material is rare earth modified ZK60 alloy, the alloy composition is wt%: 6.26Zn-0.78Zr-0.66Y-Mg, and the blank size is a rod-shaped blank with a diameter of 350mm and a height of 700mm.

[0057] 1. The implementation material is smelted in a resistance furnace, and the pouring temperature is 710°C.

[0058] 2. The molding sand ratio is wt%: fine quartz sand 85, bentonite 3.5, magnesite 6, sodium alkylsulfonate (28% aqueous solution by weight) 3, boric acid 2, industrial sugar 0.5.

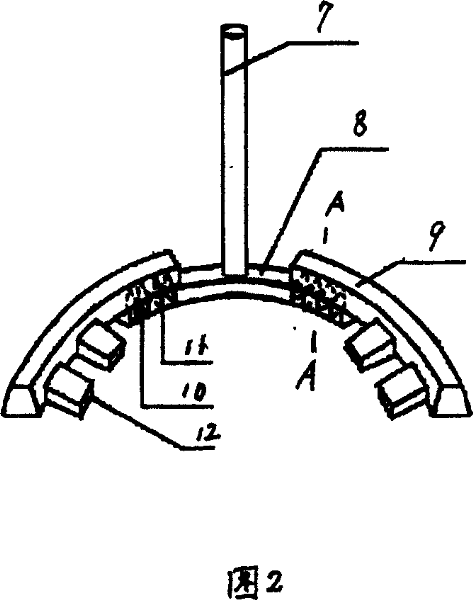

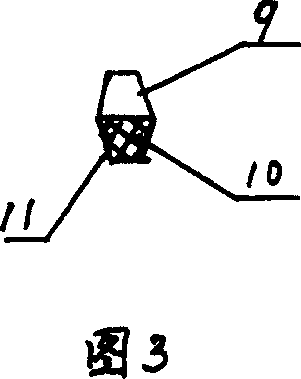

[0059] 3. An open pouring system is adopted, see Figure 2 and Figure 3. The straight gate is Φ35mm; the runner is trapezoidal: the upper and lower bottoms are 32 and 40mm, and the height is 40mm; the four rectangular inner gates are evenly distributed, and the section size of each rectangular gate is 120mm×12mm (height).

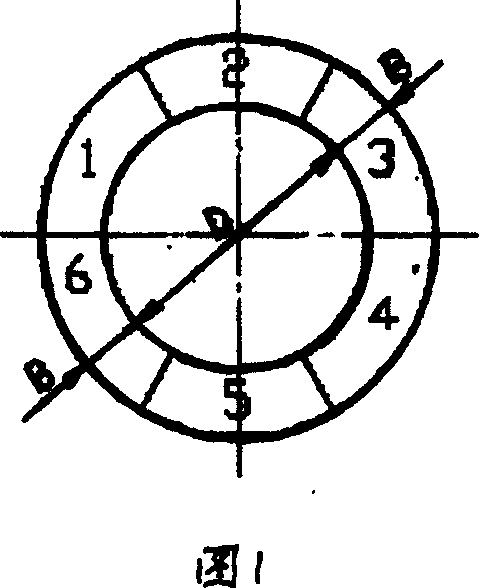

[0060] 4. The location of the cold iron around the billet is shown in Figure 1. The bottom surface and cylindrical surface of the billet are basicall...

Embodiment 2

[0064] The implementation material is rare earth modified ZK60 alloy, the alloy composition is wt%: 5.33Zn-0.89Zr-0.29Y-Mg, and the blank size is a rod-shaped blank with a diameter of 350mm and a height of 700mm.

[0065] 1. The implementation material is smelted in a resistance furnace, and the pouring temperature is 710°C.

[0066] 2. The proportion of molding sand is wt%: fine quartz sand 89, bentonite 4, acidic ammonium fluoride (NH 4 HF) 7.

[0067] 3. An open pouring system is adopted, see Figure 2 and Figure 3. The straight gate is Φ35mm; the runner is trapezoidal: the upper and lower bottoms are 32 and 40mm, and the height is 40mm; the four rectangular inner gates are evenly distributed, and the section size of each rectangular gate is 120mm×12mm (height).

[0068] 4. The location of the cold iron around the billet is shown in Figure 1. The bottom surface and cylindrical surface of the billet are basically surrounded by cold iron, so that the melt is basically not i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com