Optical background module set and its fixing mechanism

A backlight module and fixing mechanism technology, applied in optics, nonlinear optics, instruments, etc., can solve problems such as unstable assembly quality, failure to pass the impact test of the backlight module, and viscous deterioration, so as to avoid the rupture of the lamp tube , Improve the display quality, improve the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

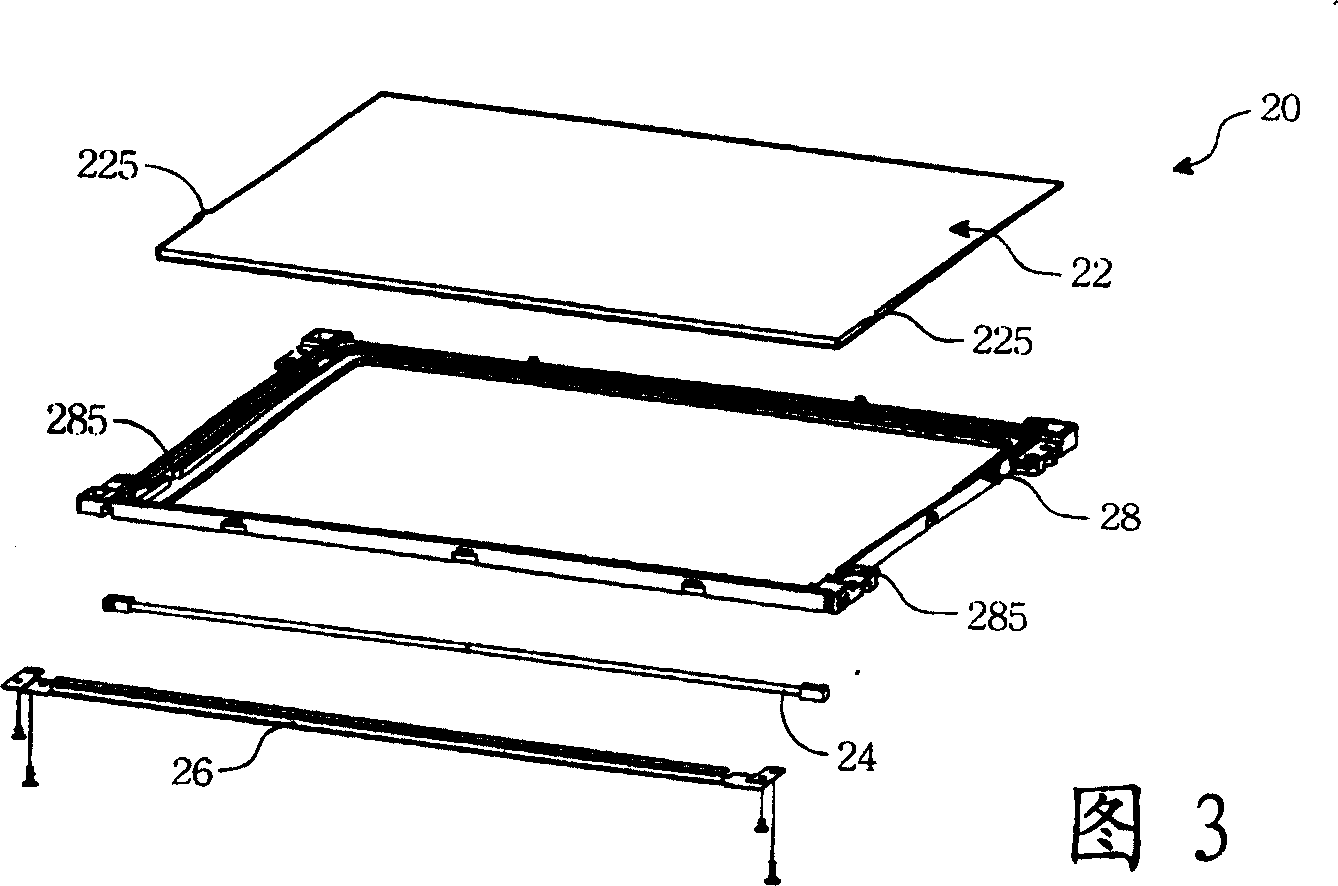

[0045] Please refer to FIG. 6 , which is an exploded perspective view of the backlight module of the present invention. The backlight module 50 includes a light guide plate 52 , a light tube 54 , a lampshade 56 and a frame 58 . The light guide plate 52 has an incident end 521 , a light output surface 522 , a front end 523 and a bottom surface 524 .

[0046] The light guide plate 52 is made of light-permeable acrylic material by injection molding, and is disposed on the frame 58 , and its bottom surface 524 corresponds to the frame 58 . The bottom surface 524 of the light guide plate is provided with a plurality of particle patterns, and its main function is to scatter or reflect light inside the light guide plate 52, so that the light can be evenly output from the light exit surface 522, such as the V pattern used in the preferred embodiment of the present invention. -cut type light guide plate, that is to use a special scraper to form a microstructure of V-shaped grooves on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com