Composite cable comprehensive pipe rack and constitutional unit thereof

A technology of integrated pipe gallery and composite cable, applied in cable installation, cable installation in tunnels, water conservancy projects, etc., can solve the problems of difficult maintenance, long construction period, serious water inflow, etc. Short cycle, easy to build effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

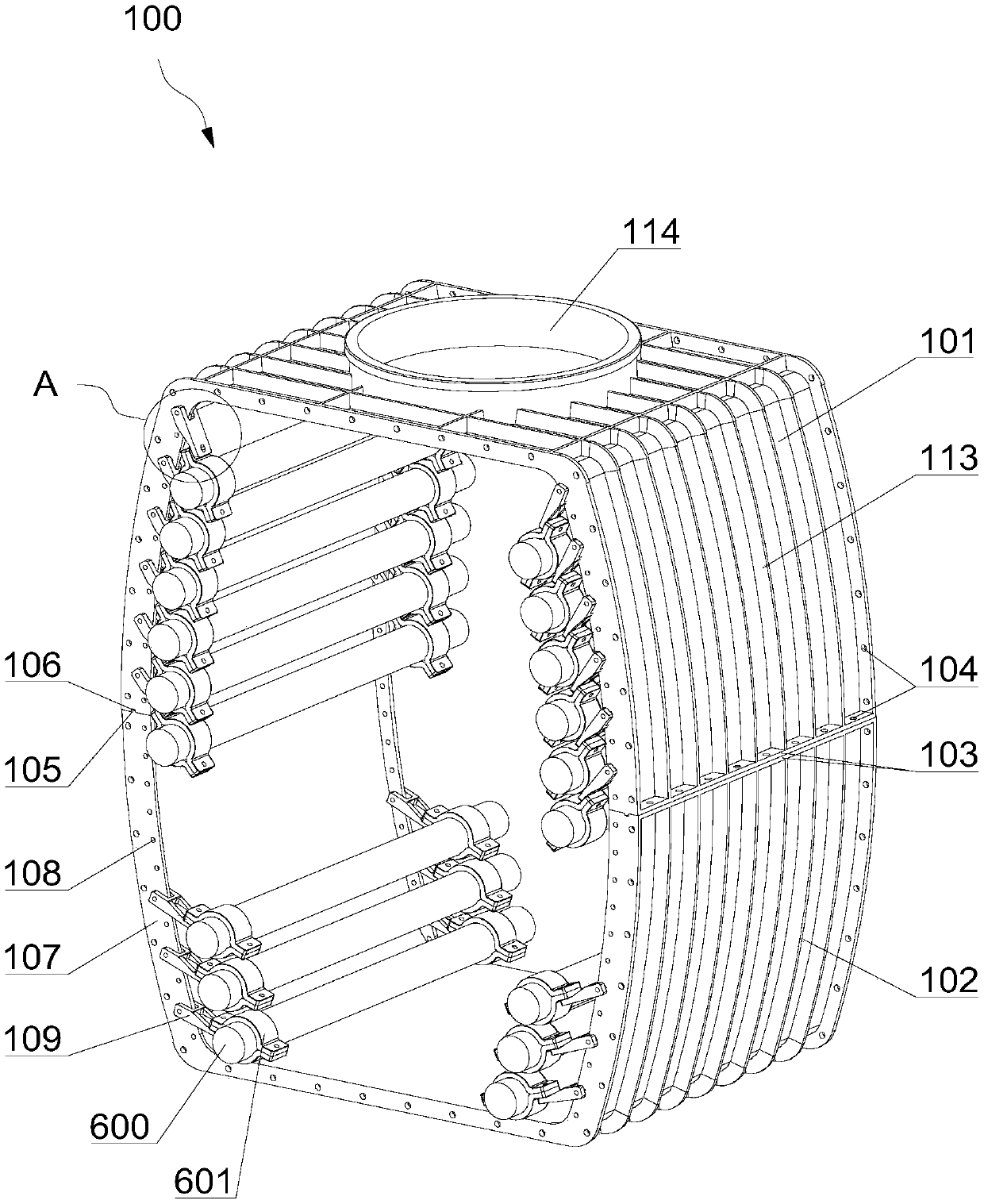

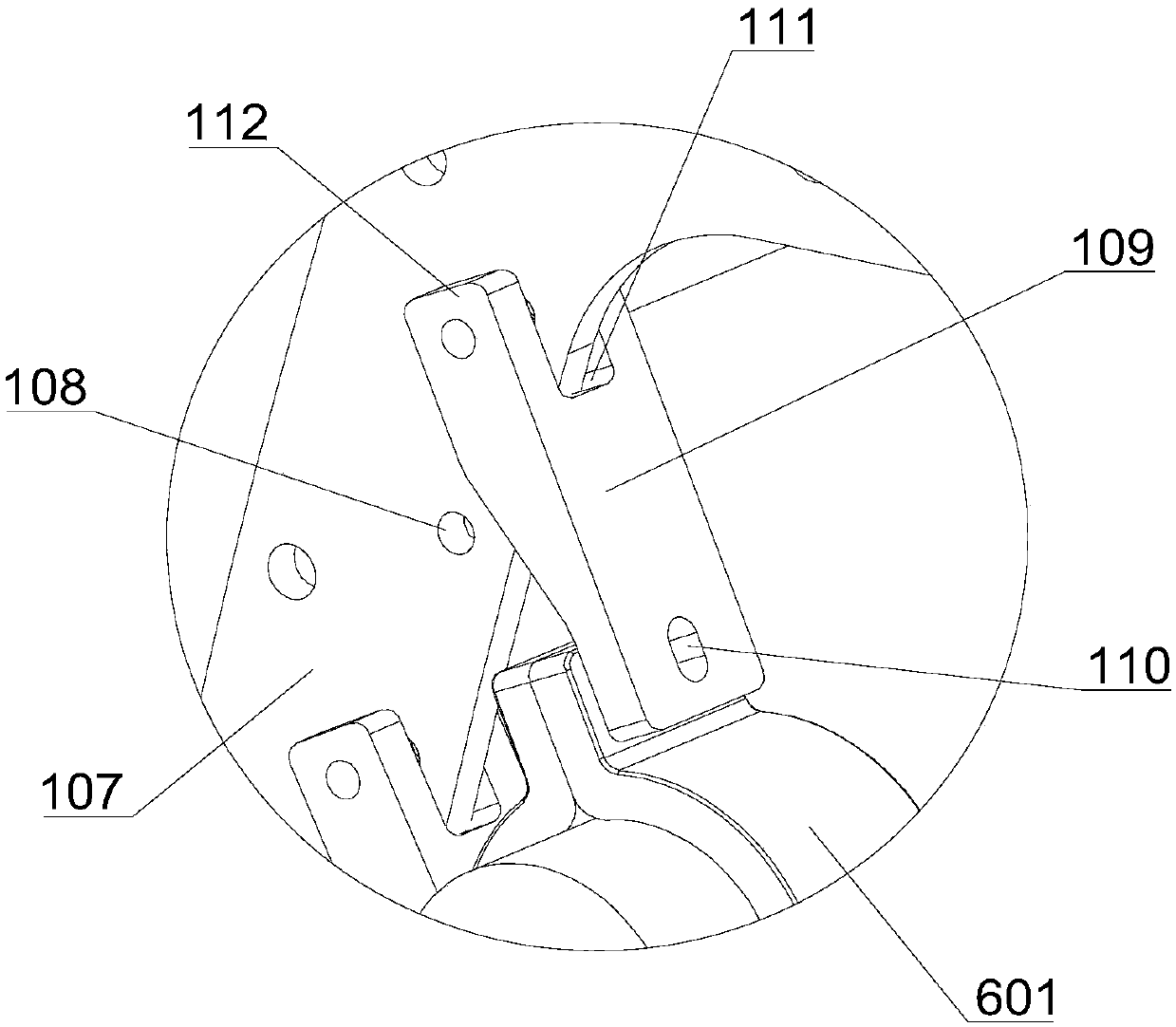

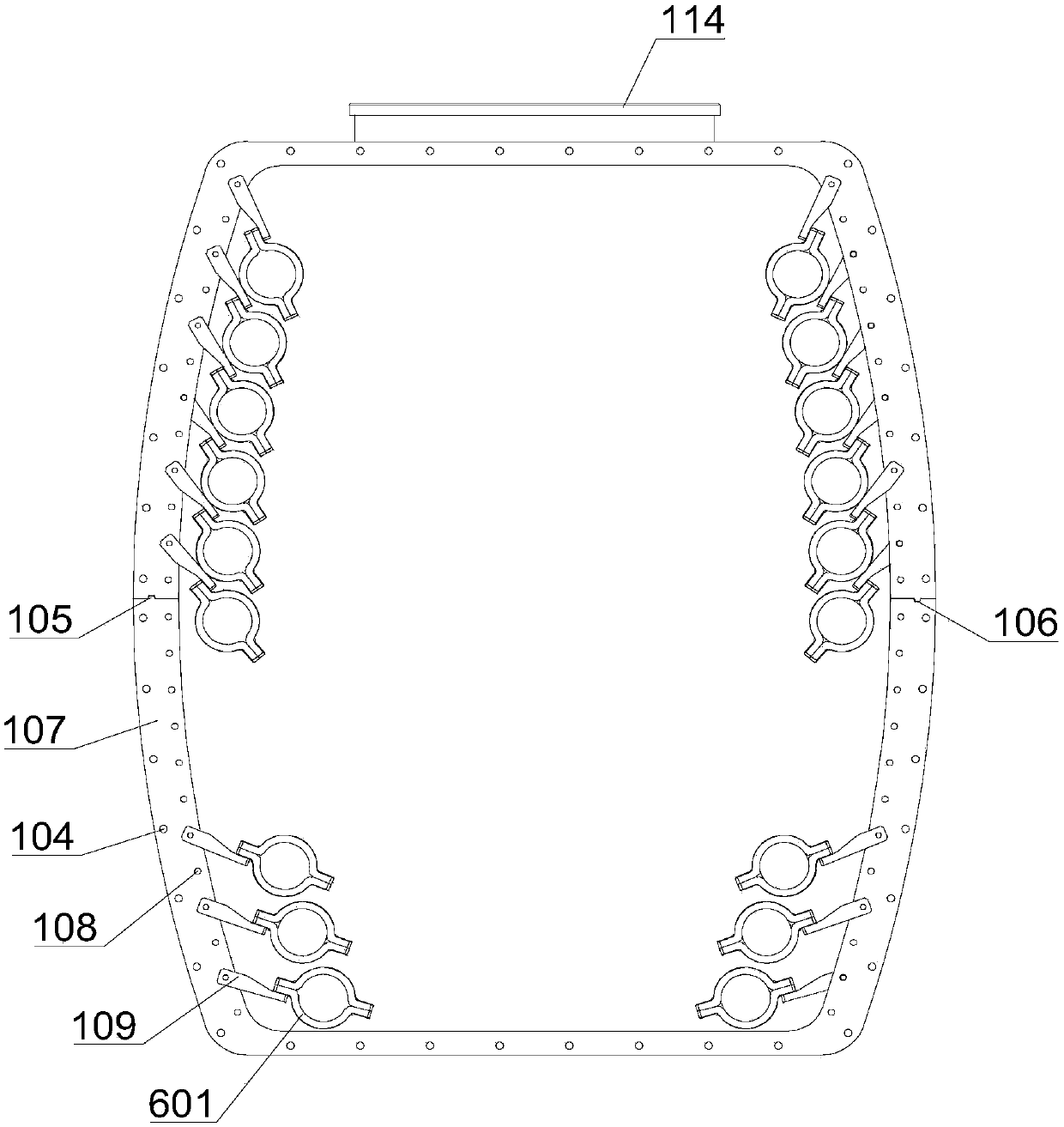

[0026] see Figures 1 to 5 As shown, this embodiment provides a composite cable integrated pipe gallery unit 100, which mainly includes an upper body part 101 and a lower body part 102, and the upper body part 101 and the lower body part 102 are combined to form a pipe gallery unit cabin. The upper body part 101 and the lower body part 102 have symmetrical structures, and both include a middle plane wall and two arc-shaped walls.

[0027] An inspection port 114 can be opened on the plane wall of the upper body 101, and a manhole cover 500 is arranged on the inspection port 114, which is convenient for personnel to enter and exit for maintenance. The plane wall of the lower body part 102 is convenient for people to walk around.

[0028] The arc-shaped pipe wall formed by the combination has a good ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com