Electricity driven traveling wave thermoacoustic refrigerator system

A technology of thermoacoustic refrigerator and electric drive, which is applied in the direction of refrigerator, gas cycle refrigerator, refrigeration and liquefaction, etc. It can solve the problems of large pressure wave generator, difficult manufacturing, difficult to adjust the phase of pressure wave and velocity wave, etc. Achieve the effects of reducing heat loss, improving performance, and suppressing circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

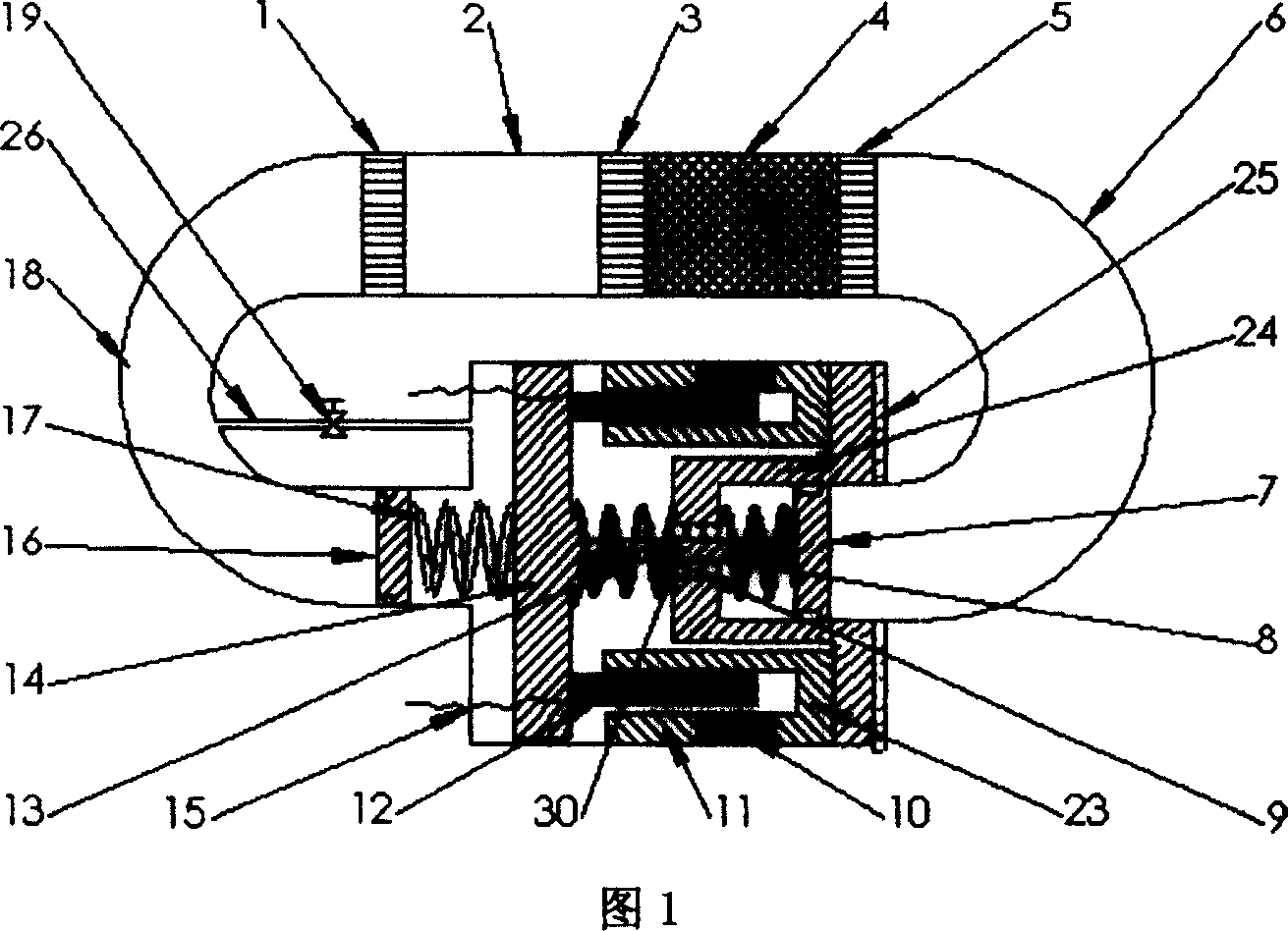

Embodiment 1

[0039] The structure of Example 1 is shown in Figure 1, including a room temperature heat exchanger 1 connected in sequence, a thermal buffer tube 2, a cold end heat exchanger 3, a regenerator 4 filled with wire mesh made of stainless steel or brass, and a hot end The heat exchanger 5 and the annular connecting pipeline also include a pressure wave generator installed in the annular pipeline. In this embodiment, one end of the pressure wave generator is connected to the "U"-shaped connecting pipe 6 derived from the hot-end heat exchanger 5, and the connecting pipe is called the hot-end pipe 6; The "U"-shaped connecting pipe 18 is called the room temperature pipe 18 . The role of the room temperature heat exchanger 1 and the thermal buffer pipe 2 is to prevent the gas oscillating back and forth from bringing heat to the cold end heat exchanger 3, which increases the loss of cooling capacity. The assembly consisting of cold end heat exchanger 3, regenerator 4 and hot end heat e...

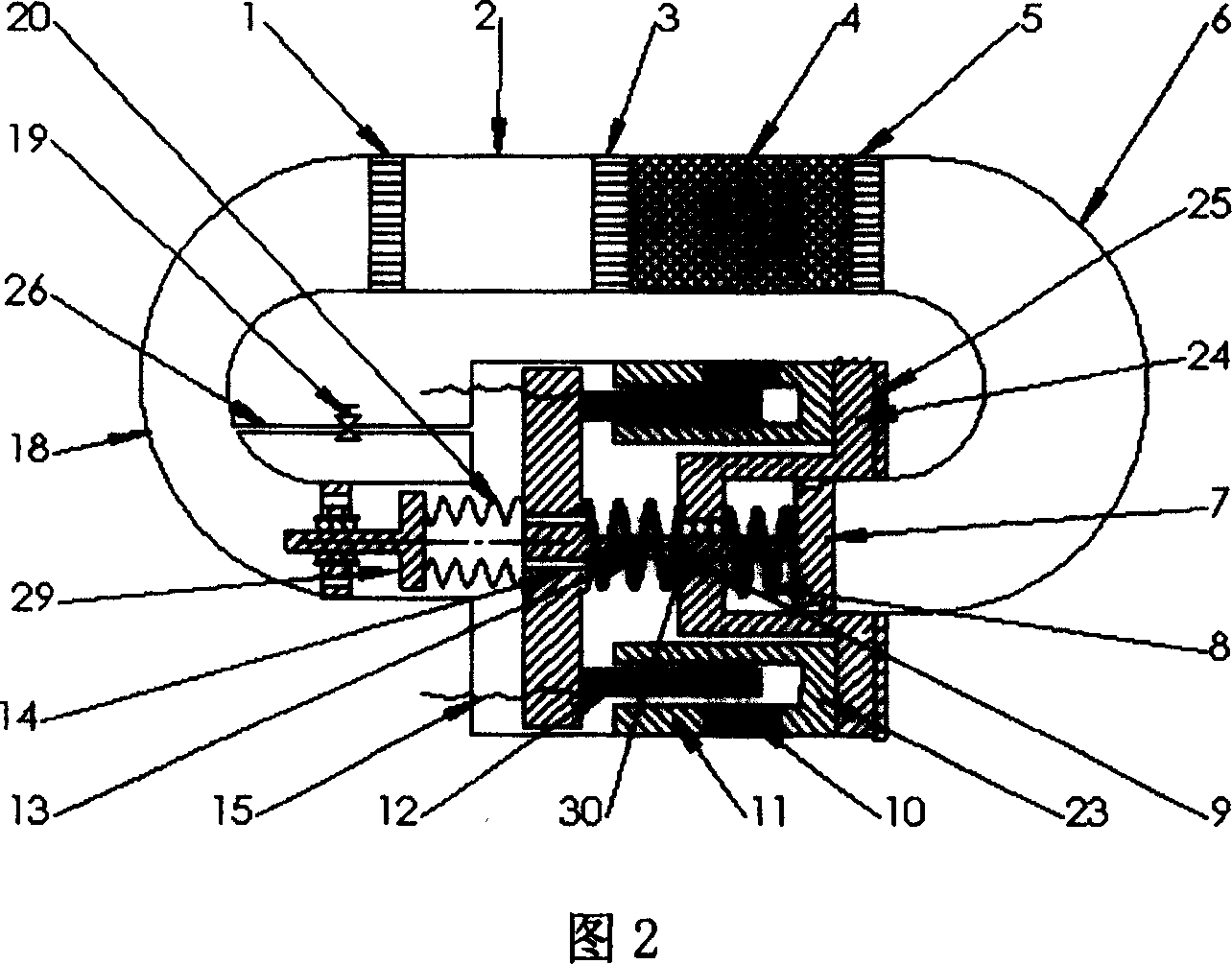

Embodiment 2

[0042] As shown in Figure 2, on the basis of Embodiment 1, this embodiment adopts a metal bellows 20 to replace the mechanical spring 17 in Embodiment 1, and adopts a mass 29 to replace the phase-modulating piston 16 in Embodiment 1; meanwhile, adopts A linear sliding bearing or a leaf spring is used to support the mass 29; a gas channel is added on the end face of the coil support 14, so that the internal gas vibration of the auxiliary bellows will not cause too much pressure fluctuation and damage the bellows. The metal bellows in this embodiment can be made of ordinary stainless steel 304, beryllium bronze and other materials. The fabrication method is usually hydroforming or welding. Generally, hydroformed bellows are stiffer than welded bellows, so they are more stable.

[0043] When working, the metal bellows 20 plays the role of the mechanical spring 17 in the first embodiment, the mass block 29 plays the role of the phase adjustment piston 16 in the first embodiment, ...

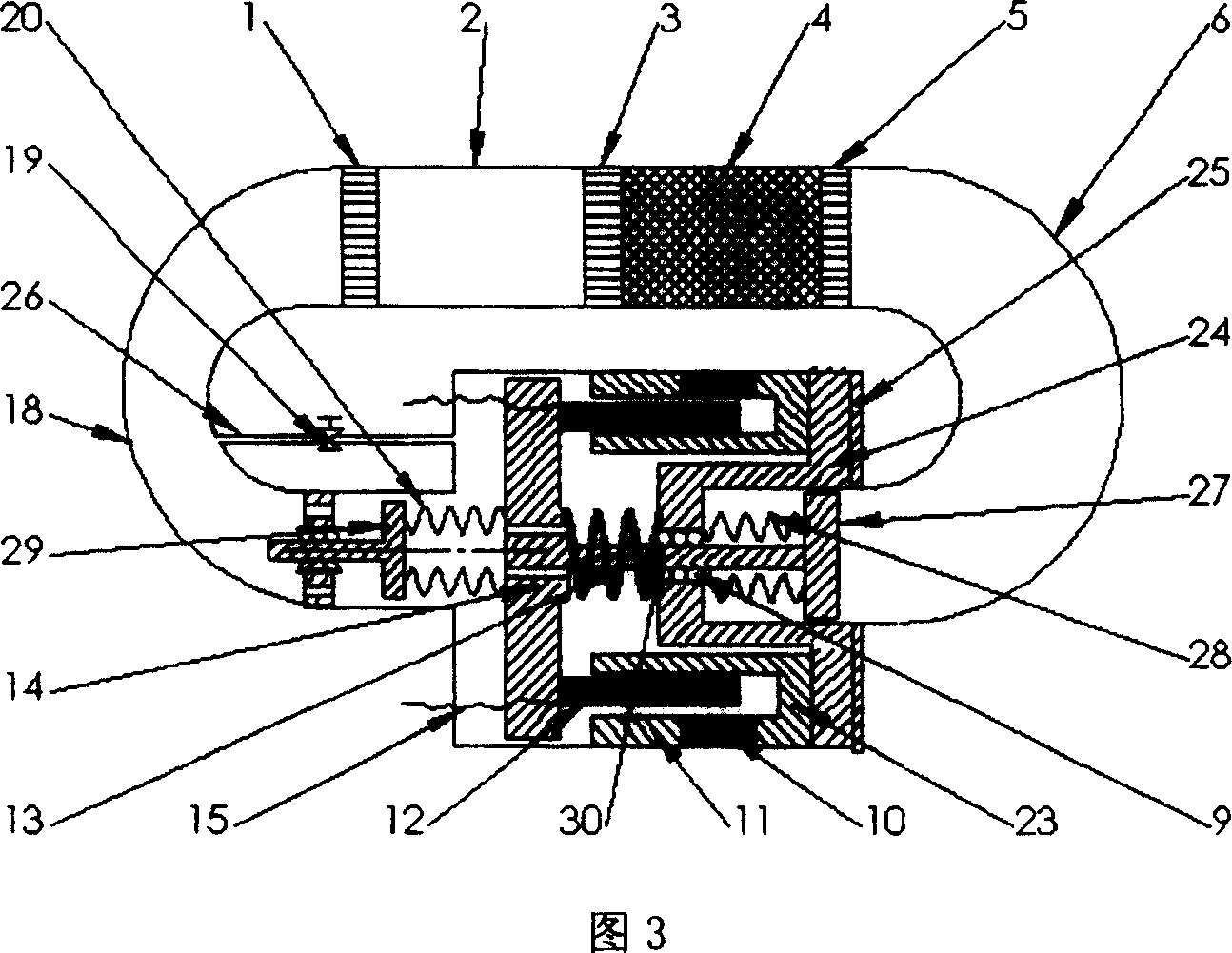

Embodiment 3

[0045] The structure of this embodiment is shown in Figure 3, which is transformed on the basis of Embodiment 2. In this embodiment, the spring-piston assembly in Embodiment 2 is replaced by the bellows-mass assembly as the scavenging elastic-mass assembly, and the materials, manufacturing processes and connection methods of the remaining parts are the same as those in Embodiment 2. The bellows-mass assembly is composed of a metal bellows 28 and a mass 27, and the linear sliding bearing 9 is fixedly connected with the mass 27 to play a supporting role.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com