Device for making artificial snow

A technology for artificial snowmaking and equipment, applied in lighting and heating equipment, ice making, recreational ice making, etc., can solve the problems of reducing icing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Preferred embodiments of the present invention are described below with reference to the accompanying drawings. In the following description, in order to avoid redundancy, some well-known functions and structures will not be described in detail.

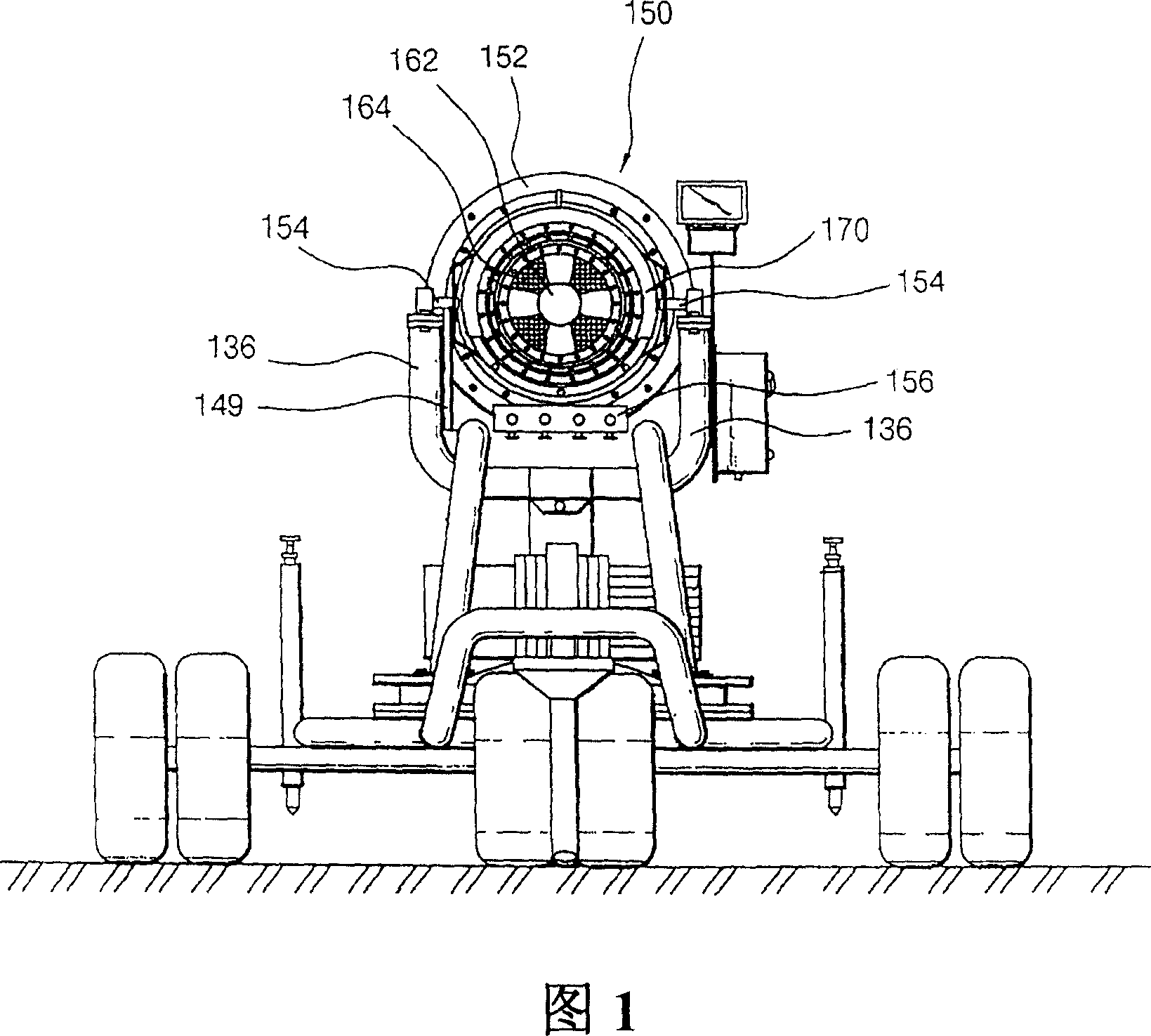

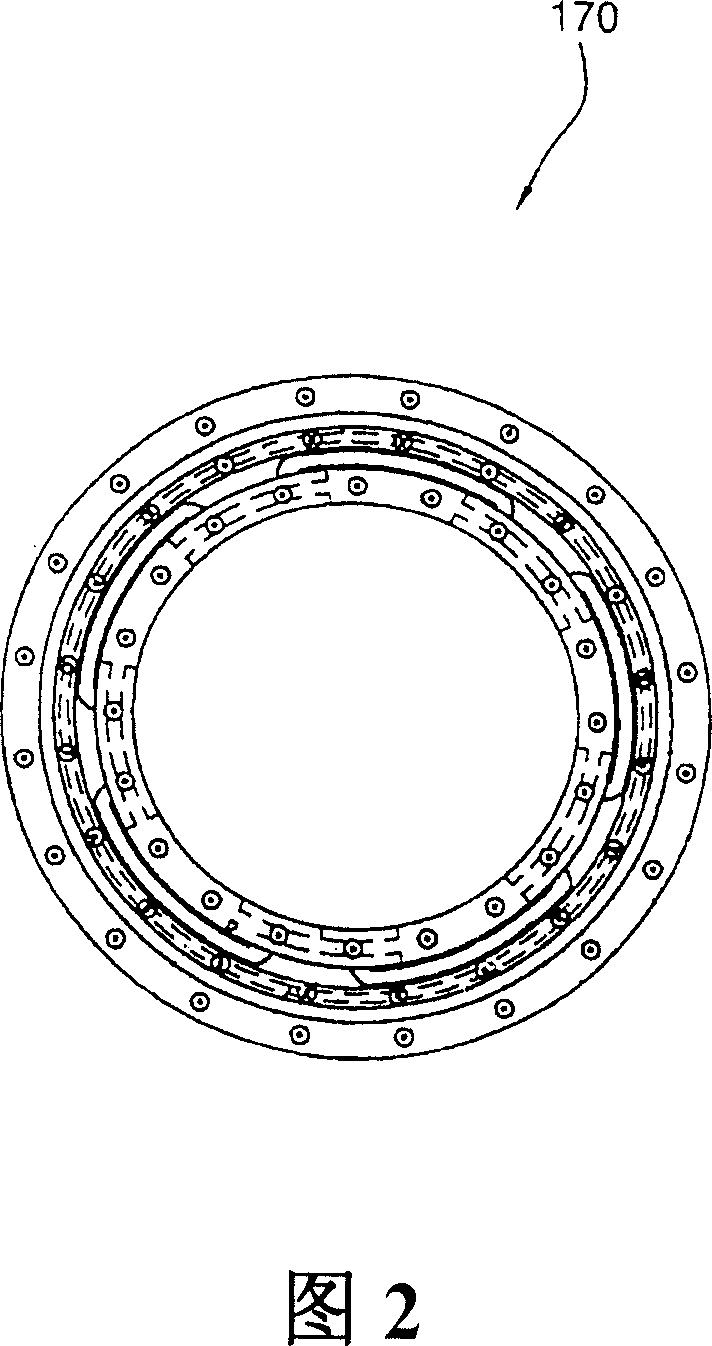

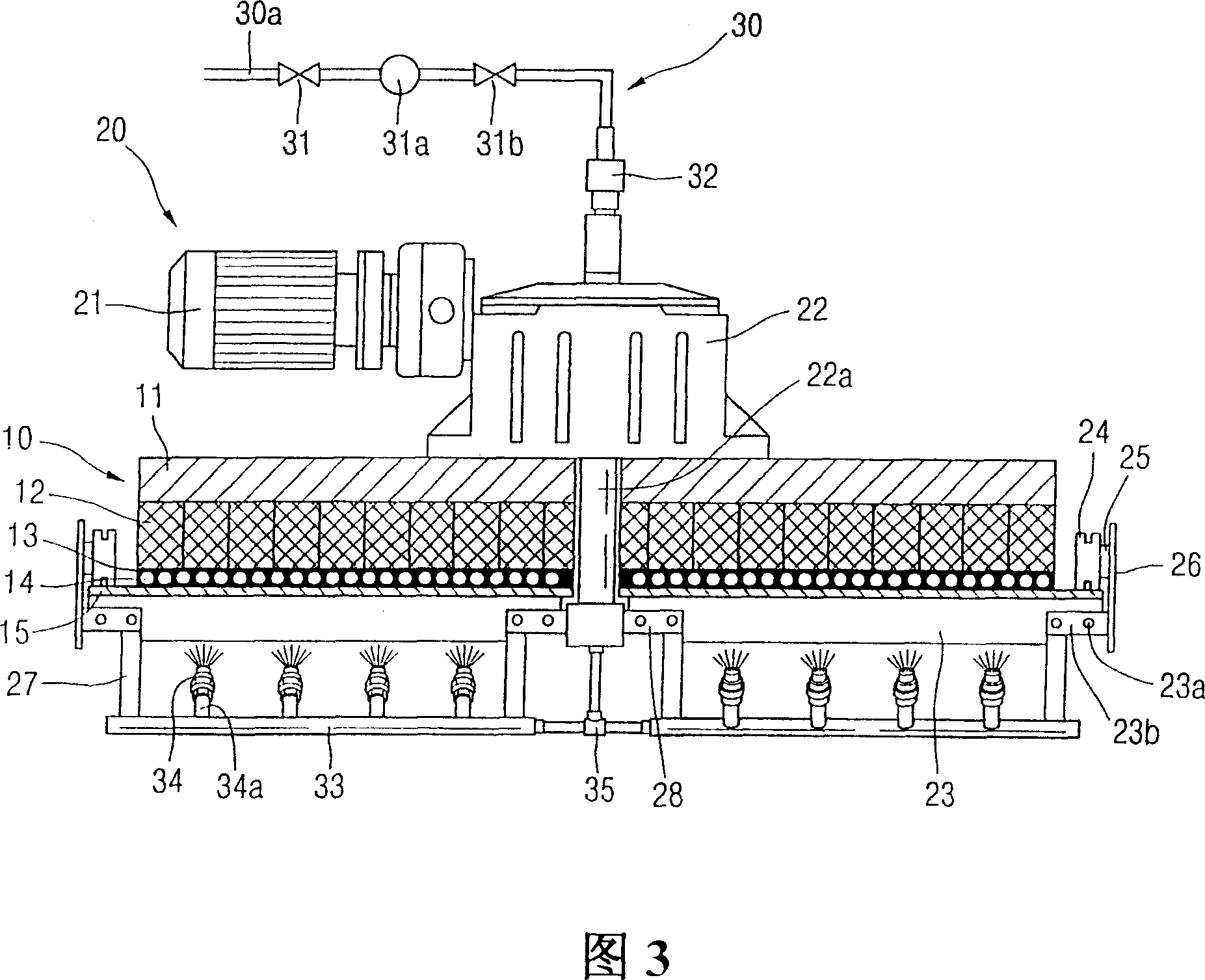

[0024] The artificial snowmaking equipment according to the present invention comprises a hot and cold plate 10 having a chassis 11, a thermally conductive material 13 filled outside the evaporation line 14, and an icing plate 15, a cutting unit comprising a motor 21, a reduction gear 22, a blade 23 and a roller 24 20, and a water supply unit 30 comprising a pump 31a, a swivel joint 32 and a distribution line 33 equipped with a nozzle 34. The artificial snow making equipment further includes an automatic door device on the lower surface of the hot and cold plate unit 10 .

[0025] Referring to FIG. 3 , the artificial snowmaking equipment includes a hot and cold plate unit 10, which includes a chassis 11 on which a heat insula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com