Conductive metal resin multilayer body and molded body of same

A technology of conductive metal and laminates, applied in the direction of metal layered products, synthetic resin layered products, circuits, etc., can solve the problems of exposed metal, etc., achieve easy control of conductivity, reduce process load, and excellent handling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

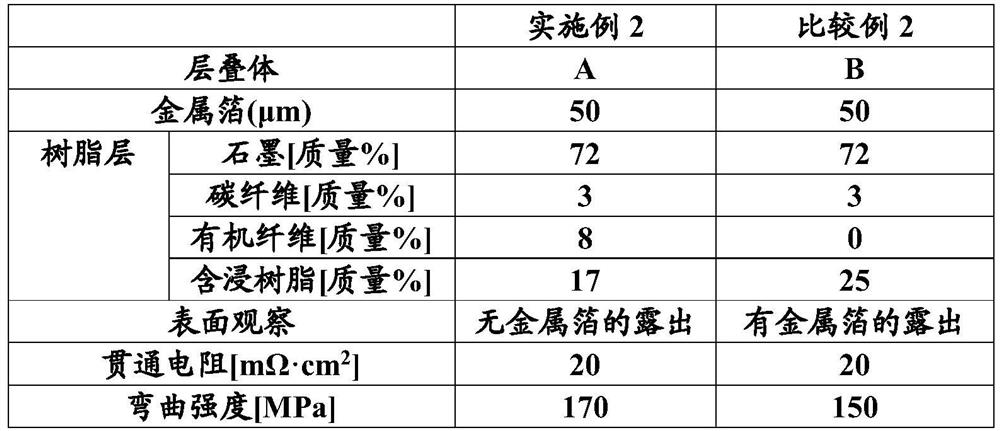

[0082] Hereinafter, the present invention will be described more specifically with reference to production examples, examples, and comparative examples, but the present invention is not limited to the following examples. In addition, the materials used in the following Examples are as follows.

[0083] ·Natural graphite: average particle size 25μm

[0084] ·PAN-based carbon fiber: average fiber length 3.0mm, average fiber diameter 7μm

[0085] · Poly-p-phenylene terephthalamide fiber: average fiber length 0.9mm, average fiber diameter 10μm, decomposition temperature 500°C

[0086] [1] Production of conductive sheet

manufacture example 1

[0088] 87 parts by mass of natural graphite, 3 parts by mass of PAN-based carbon fiber, and 10 parts by mass of aramid fiber were put into water and stirred to obtain a fibrous slurry. Papermaking was performed on this slurry, and the electroconductive sheet A was produced. The basis weight of conductive sheet A is 78g / m 2 .

[0089] [2] Preparation of resin solution

manufacture example 2

[0091] 71.8 parts by mass of NC-3000 (Nippon Kayaku Co., Ltd.) as an epoxy resin, 27.9 parts by mass of Fenolite (registered trademark) TD2090 (registered trademark) as a curing agent, and キュアゾール (registered trademark) as a curing accelerator 0.3 parts by mass of trademark) 2PZ (Shikoku Chemical Industry Co., Ltd.) was dissolved in 100 parts by mass of acetone to prepare a 50% by mass resin solution A.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com