Self-closing dispensing head

An output head, self-closing technology, applied in the direction of transportation and packaging, injection devices, liquid distribution, etc., can solve the problem of bacterial intrusion, etc., and achieve the effect of good circulation, high precision, and low assembly cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

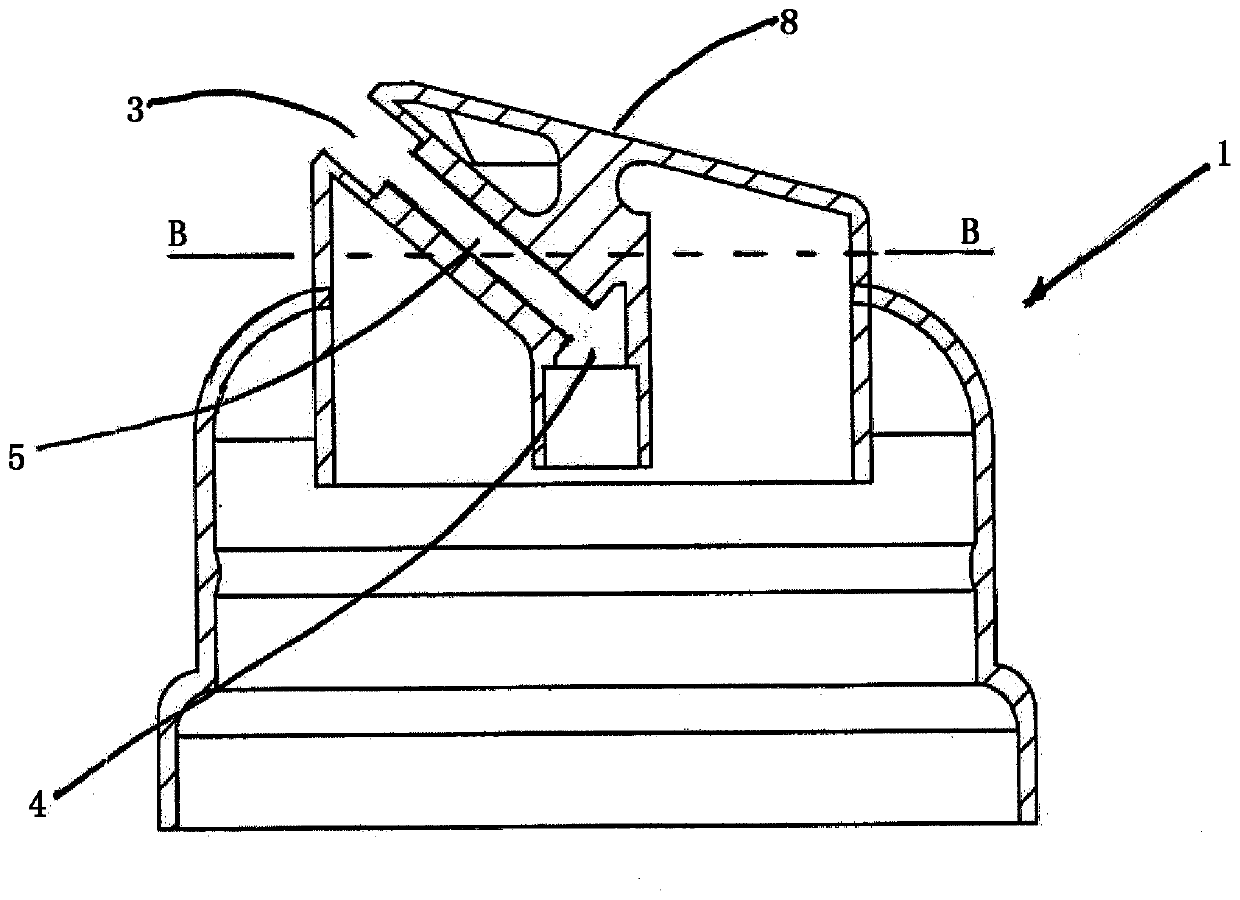

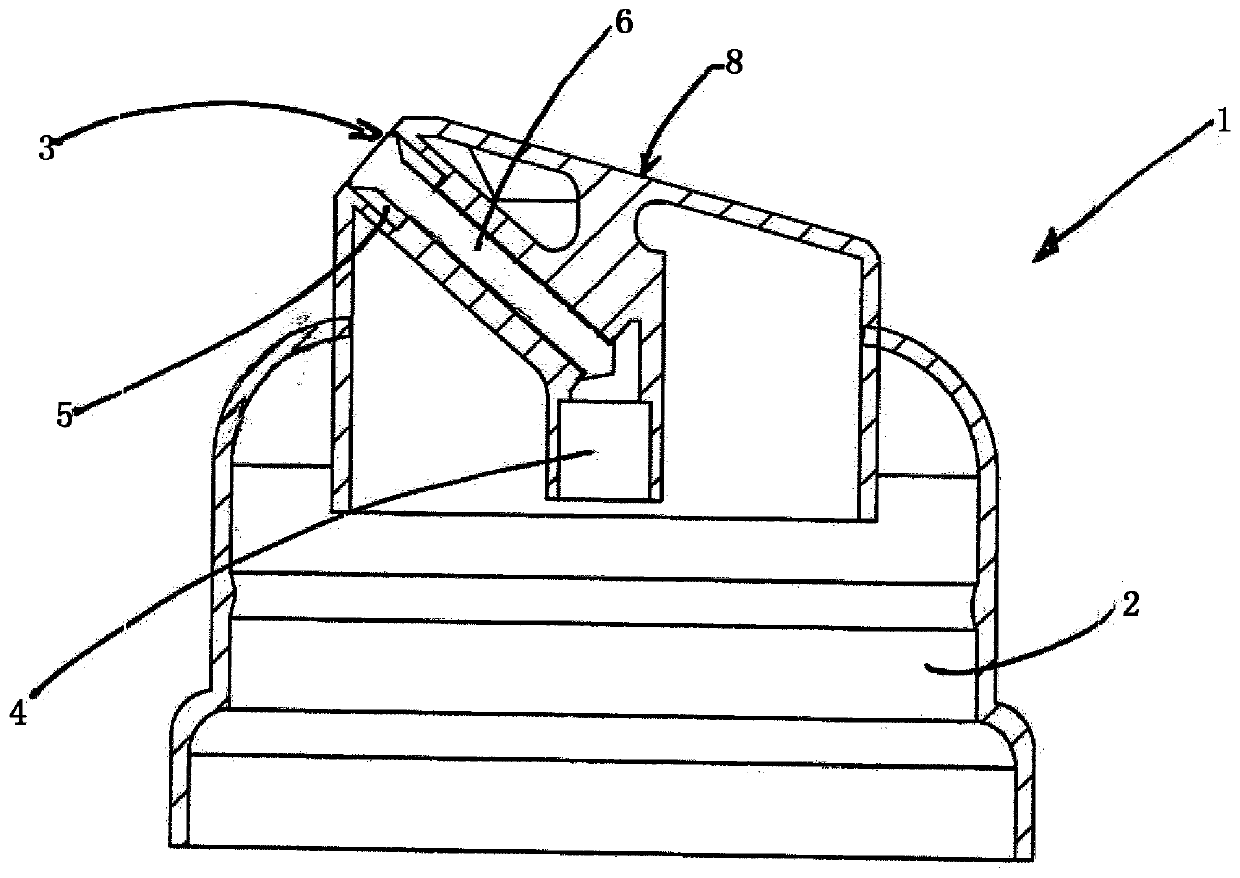

[0032] FIG. 1 shows an output head 1 , which is preferably constructed in one piece. The dispensing head has a housing 2 which is mounted or integrally connected to the container and to a dispensing valve (not shown in greater detail) for dispensing a medium, for example a viscous self-foaming and / or gel-like product. The dispensing valve is assigned to the inner container space filled with the medium and can be actuated by means of an opening mechanism by pressing the actuating surface 8 of the dispensing head.

[0033] The outlet head has an outlet opening 3 which is in flow connection via a first channel section 4 and a second channel section 5 . The second channel section is equipped with a closing element designed as a closing piston 6 , which closes the outlet opening 3 .

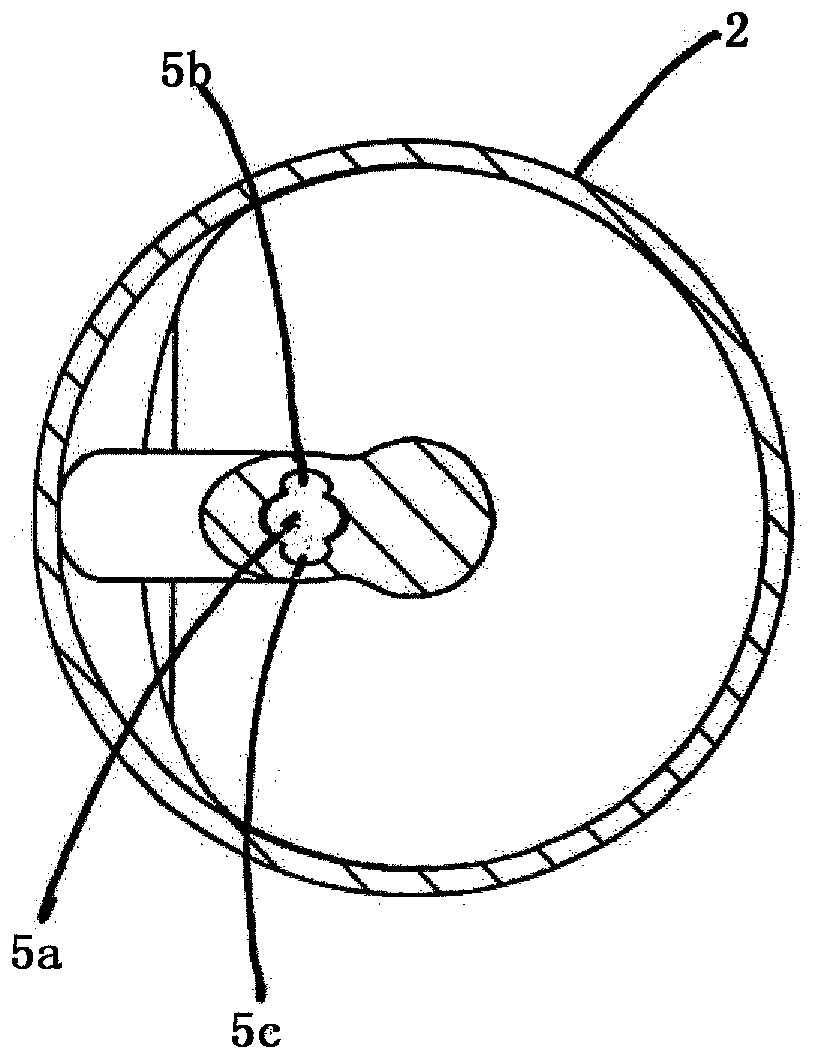

[0034] Close piston 6 ( image 3 ) has a solid cylindrical handle 6b, at one end of which is molded in the form of a conical barb 6a made of soft flexible material. On the side opposite the barb 6a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com