A kind of water-based lubricating medium for ship closed water lubricating propulsion system and preparation method thereof

A technology of lubricating medium and propulsion system, applied in lubricating parts, lubricating composition, engine lubrication, etc., can solve the problems of equipment material falling off, reducing service life, damaging shafts and bearings, etc., to prolong service life and reduce air bubbles The formation, fast defoaming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

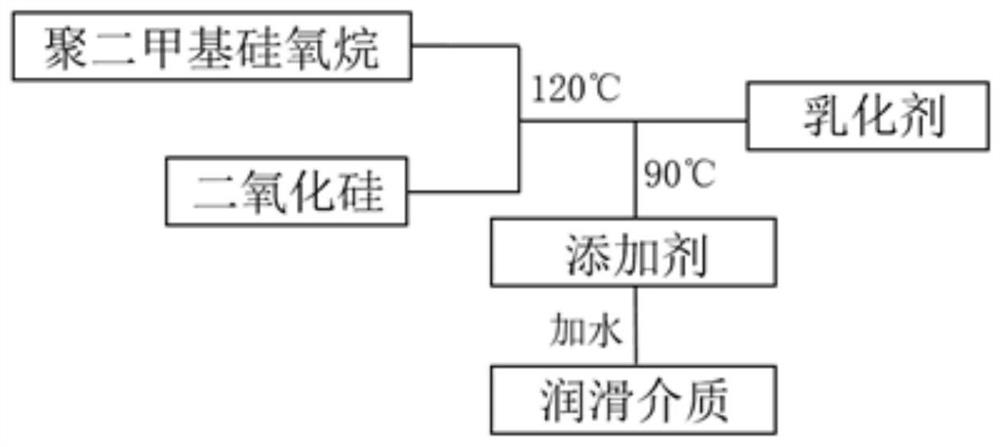

[0036] The preparation method of water-based lubricating medium is as follows:

[0037] Mix and stir polydimethylsiloxane and silica nanoparticles at a mass ratio of 10:1, raise the temperature to 120° C. and continue stirring for more than 1 hour to obtain a mixed solution. In order to make the main defoaming medium blend well with water, an emulsifier is added to the mixed solution (mixture of polydimethylsiloxane and emulsion), and the mixed solution (polydimethylsiloxane) after adding the emulsifier Alkanes and emulsified liquid mixture) cooled to 90°C and continued to stir until it was stirred into a milky white liquid, and the additive for the water-based lubricating medium was completed. Add additives to water at a mass ratio of 1:200 to make the water-based lubricating medium. The addition of polydimethylsiloxane increases the viscosity of the water-based lubricating medium, enabling the formation of a thicker lubricating film between friction pairs, increasing the be...

Embodiment 2

[0039] The preparation method of water-based lubricating medium is as follows:

[0040]Mix and stir polydimethylsiloxane and silica nanoparticles at a mass ratio of 5:1, raise the temperature to 120° C. and continue stirring for more than 1 hour to obtain a mixed solution. In order to make the main defoaming medium blend well with water, an emulsifier is added to the mixed solution (mixture of polydimethylsiloxane and emulsion), and the mixed solution (polydimethylsiloxane) after adding the emulsifier Alkanes and emulsified liquid mixture) cooled to 90°C and continued to stir until it was stirred into a milky white liquid, and the additive for the water-based lubricating medium was completed. Add additives to water at a mass ratio of 1:200 to make the water-based lubricating medium.

Embodiment 3

[0042] The preparation method of water-based lubricating medium is as follows:

[0043] Mix and stir polydimethylsiloxane and silica nanoparticles at a mass ratio of 10:1, raise the temperature to 120° C. and continue stirring for more than 1 hour to obtain a mixed solution. In order to make the main defoaming medium blend well with water, an emulsifier is added to the mixed solution (mixture of polydimethylsiloxane and emulsion), and the mixed solution (polydimethylsiloxane) after adding the emulsifier Alkanes and emulsified liquid mixture) cooled to 90°C and continued to stir until it was stirred into a milky white liquid, and the additive for the water-based lubricating medium was completed. Add additives to water at a mass ratio of 1:600 to make the water-based lubricating medium.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com