Wrench-type clip for folder

A technology of folders and clips, which is applied to folders, applications, household stoves, etc., can solve the problems of operating folder damage and damage, and achieve the effect of preventing accidental damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

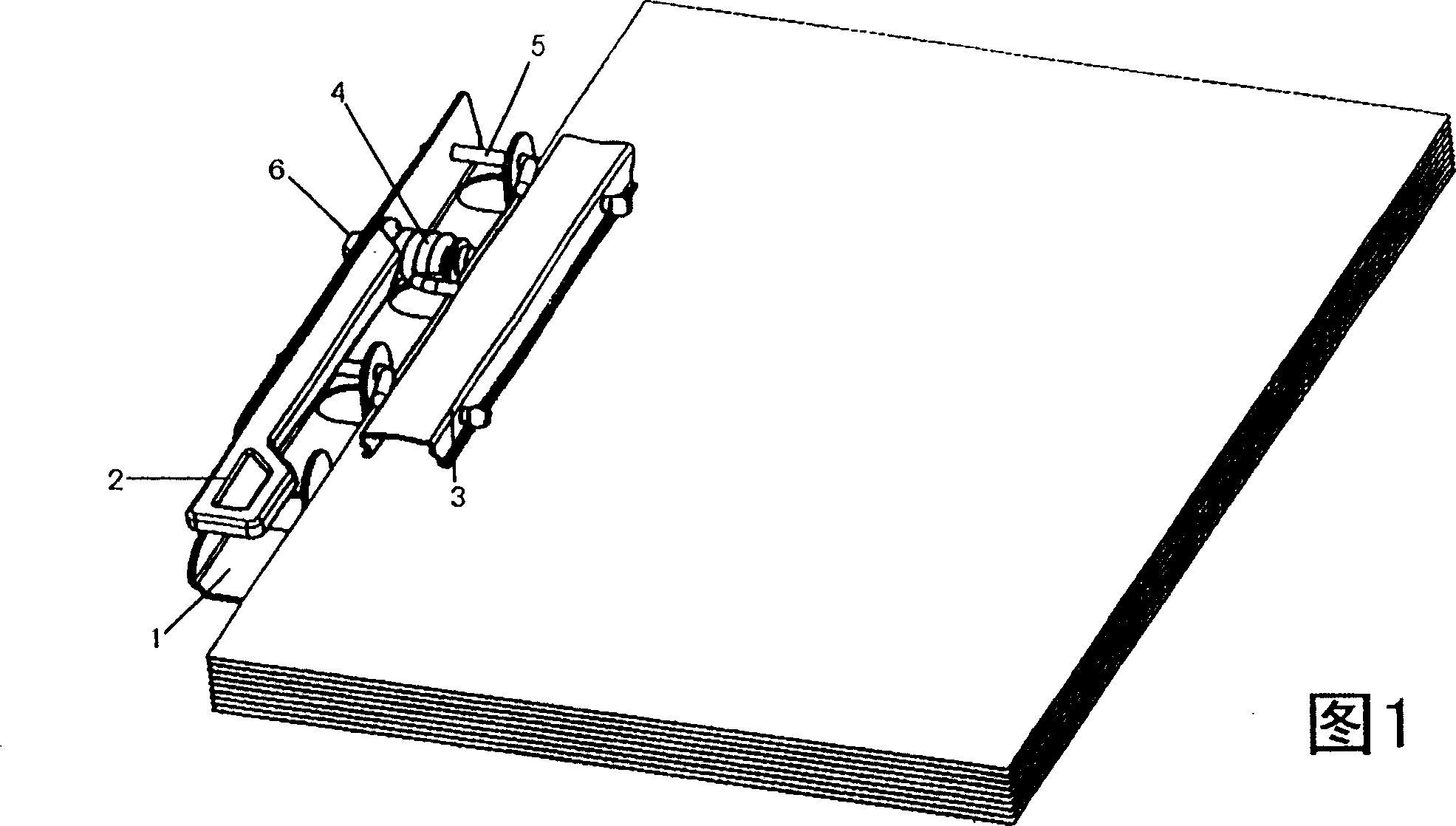

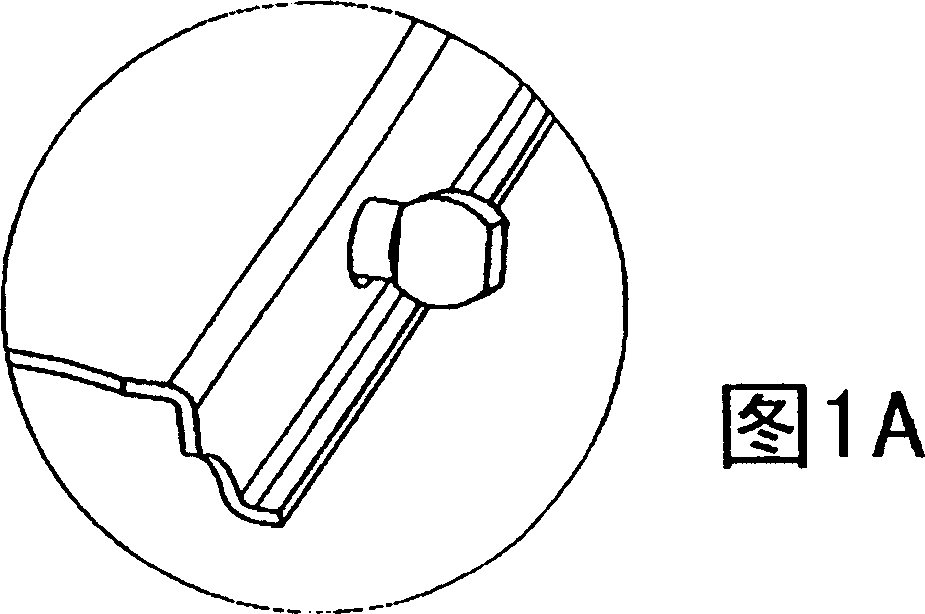

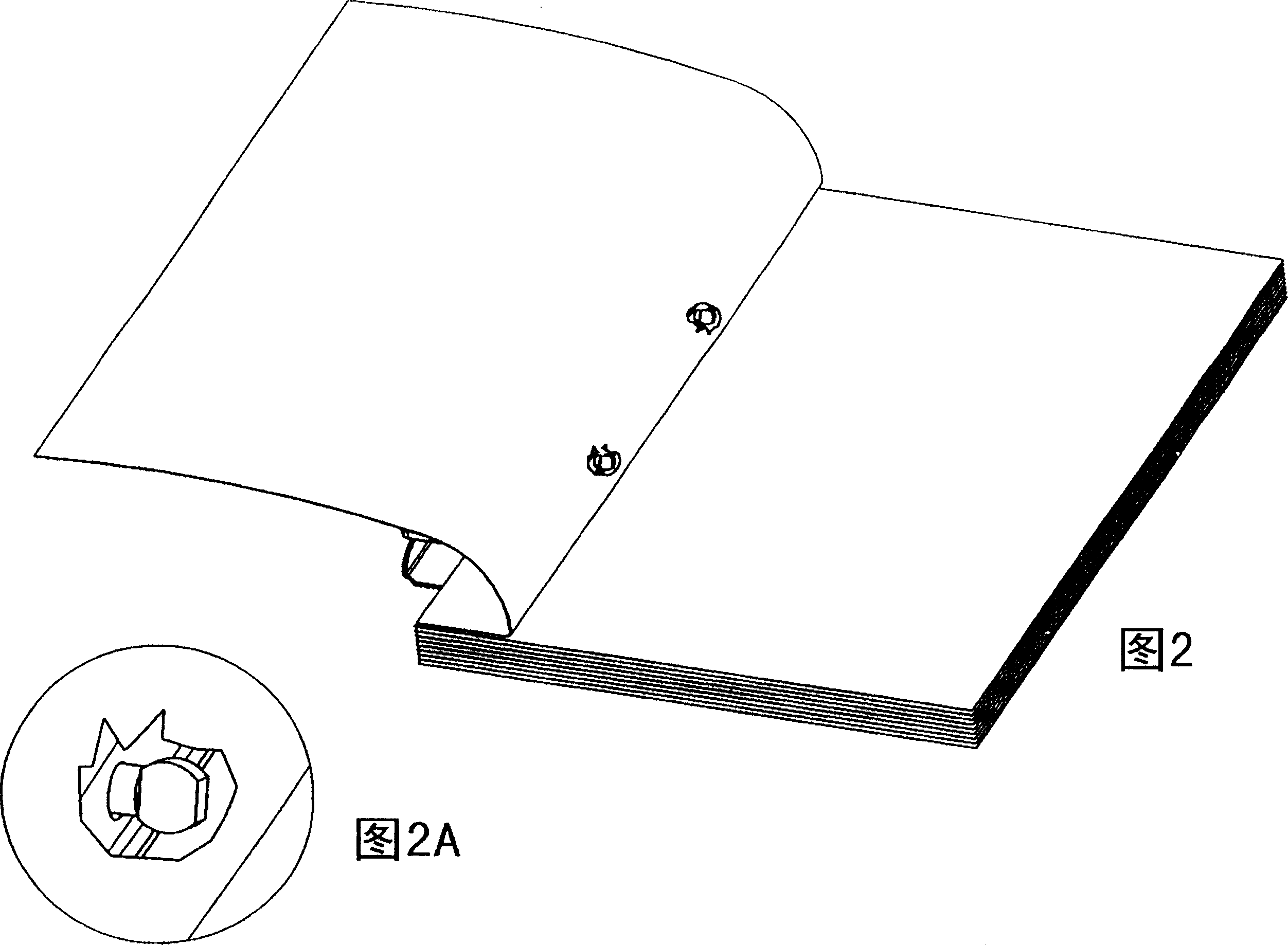

[0040] Figures 4-9 describe the first embodiment of the invention. The structure and working principle of the first embodiment of the present invention are basically the same as those of the existing wrench-type clamp, and will not be described in detail here, but only the improvements of the present invention will be described in detail.

[0041]As shown in FIG. 7, the wrench type clip of the first embodiment of the present invention includes a bottom plate 1, a handle 2, a pressure bar 3, a torsion spring 4, a rotating arm 5 and a pin 6. The bottom plate 1 has a flat L-shaped cross-sectional structure formed by a vertical side wall part and a bottom wall part, and a plurality of cuts from the bottom wall are formed on the substantially middle position of the bottom wall of the bottom wall and facing each other. The tab 7 bent to the vertical position on the bottom wall. The part on the side wall corresponding to the convex piece 7 is concavely curved inward to form a cut concave...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com