Vacuum evaporation plating machine

An evaporation machine, vacuum technology, applied in the direction of vacuum evaporation plating, sputtering plating, ion implantation plating, etc., can solve the problems of difficult thin film, difficult vapor volume, etc., and achieve the effect of uniform evaporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

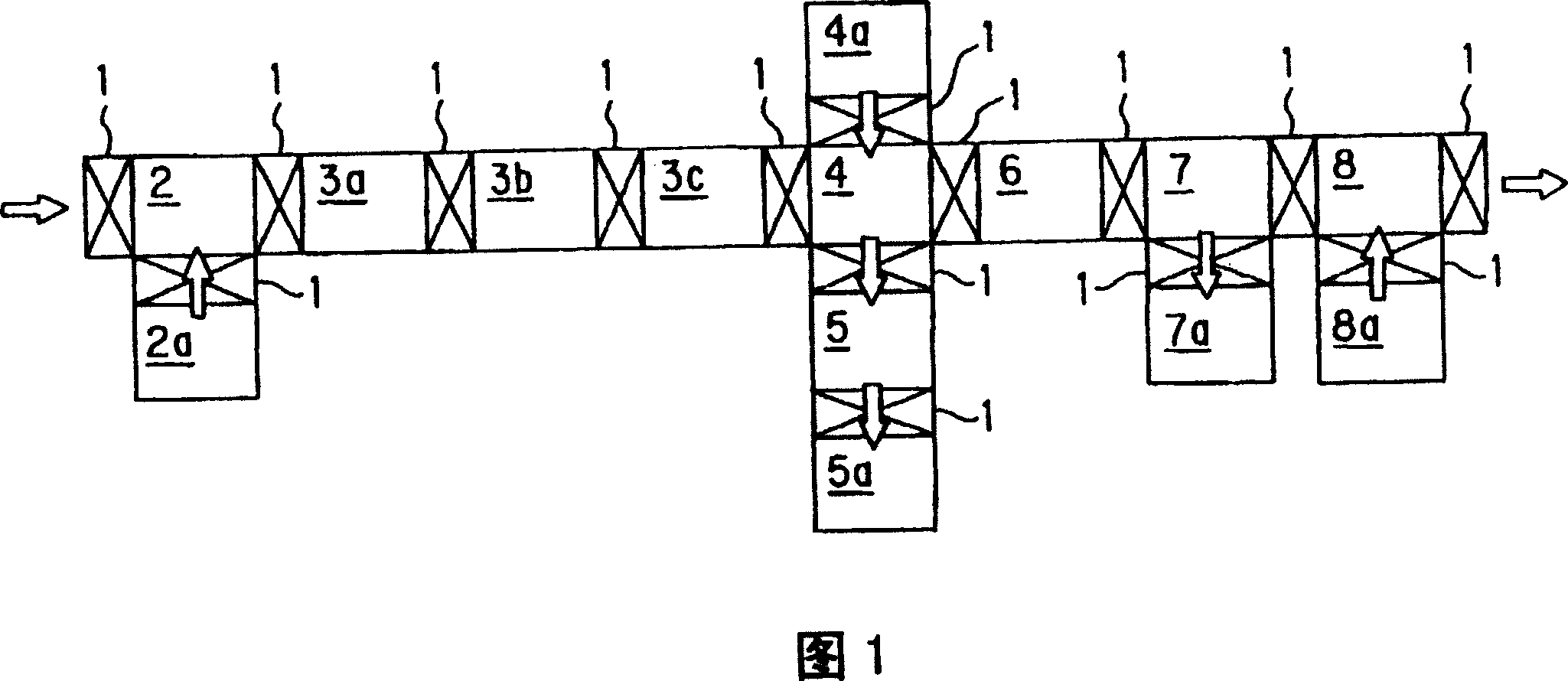

[0032] FIG. 1 is a schematic plan view showing an in-line film forming apparatus using a plurality of vacuum vapor deposition machines according to the present invention.

[0033] Hereinafter, as an example of an embodiment, the formation of an organic EL element of an FPD will be described as an example, but the vacuum vapor deposition machine of the present invention is not limited thereto, that is, it can be applied to the formation of other thin films on other substrates. In addition, the present invention is well suited for large substrates.

[0034] The in-line film forming apparatus shown in FIG. 1 is configured to form organic EL elements of FPDs in an in-line manner, and each processing chamber is provided with a gate door 1, and each processing chamber is provided with a different gate door. The process according to each purpose is carried out under the same vacuum condition.

[0035] Specifically, a glass substrate to be an FPD is conveyed from the left side in FIG...

Embodiment 2

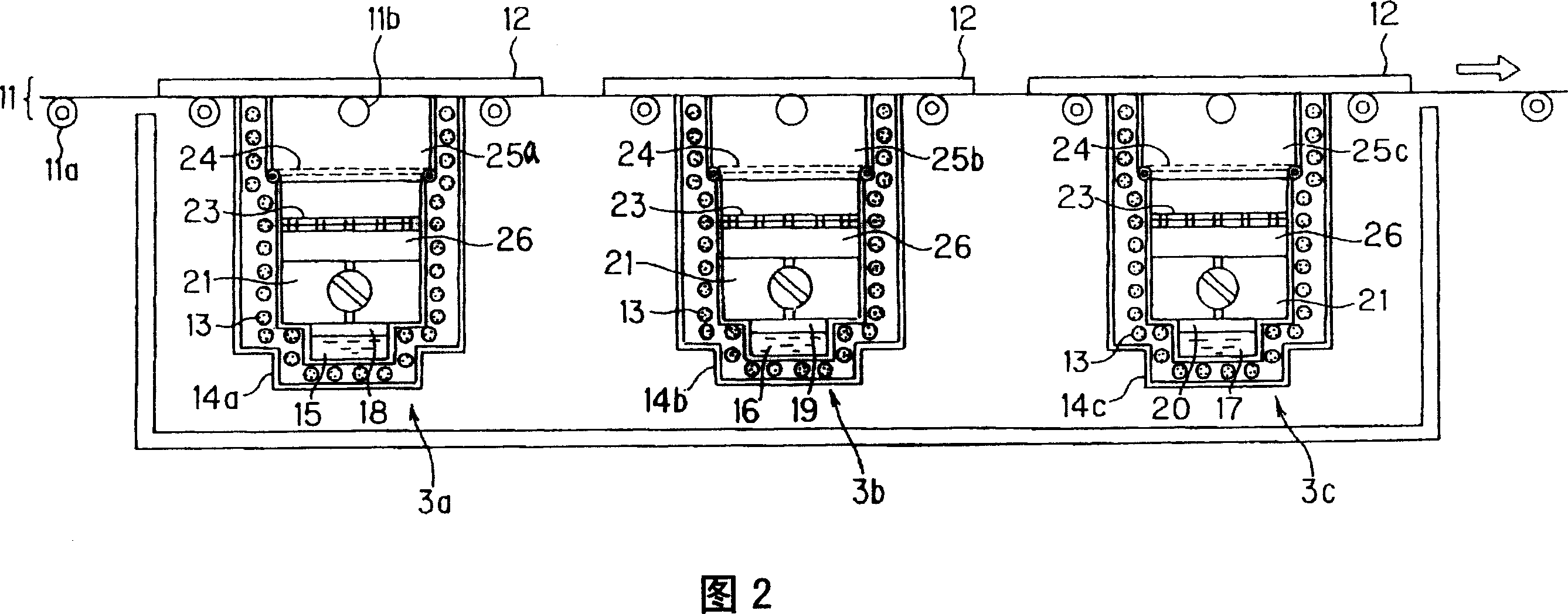

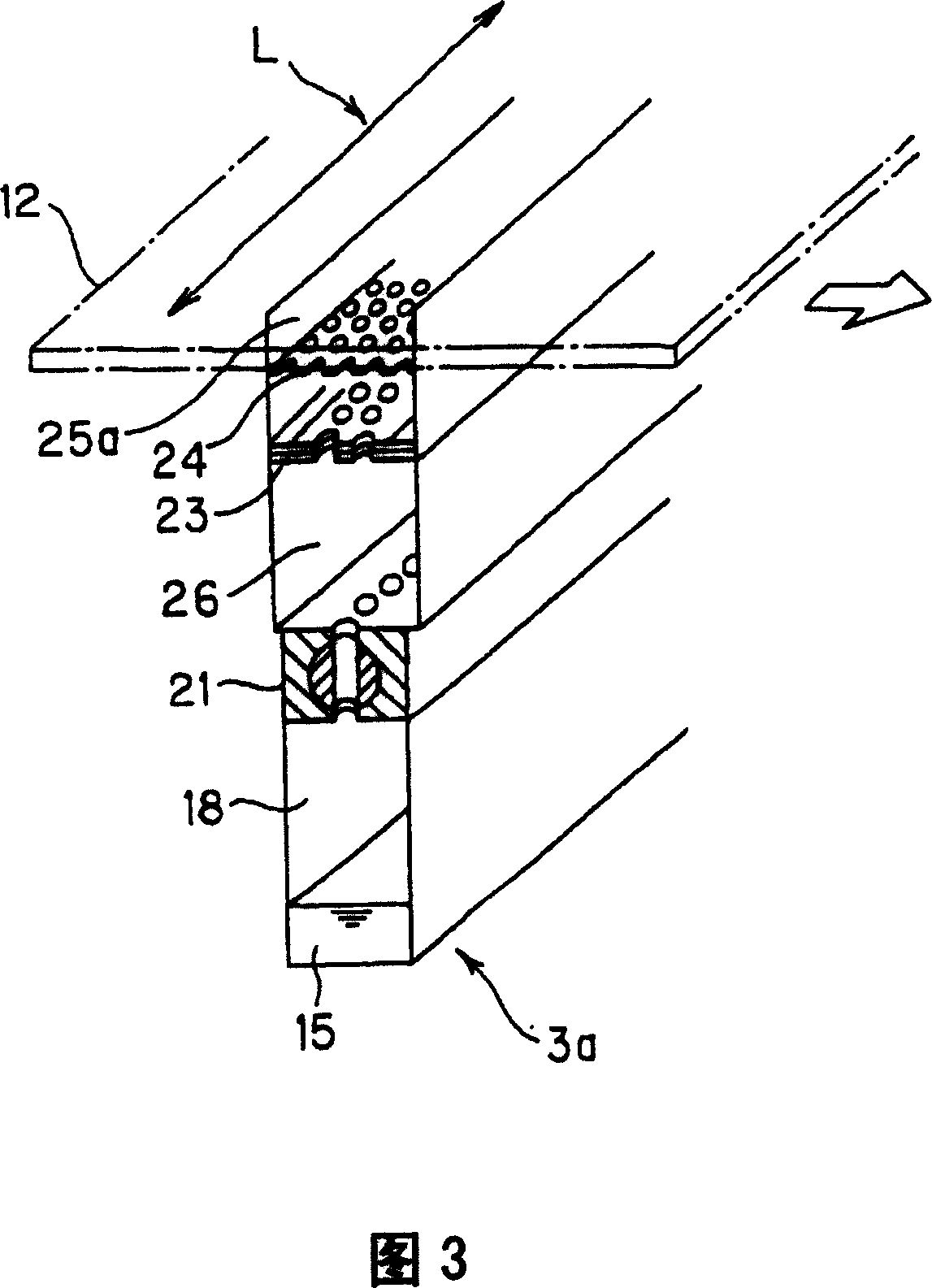

[0047] The valve member 21 is used to supply a uniform amount of vapor (concentration distribution) in the plate width direction L of the glass substrate 12, and the arrangement and direction of the flow path through which the vapor passes are not particularly limited as long as the same function can be achieved. Specifically, the valve member 21 has a structure in which, in order to uniformly supply the vapor amount of the vapor deposition material in the plate width direction L direction of the glass substrate, with respect to the vapor deposition chamber long in the plate width direction L direction, the plate A plurality of flow paths are provided in the direction of the width direction L, and the amount of steam passing through these flow paths can be independently controlled. Next, the mechanism and operation of the valve member 21 having the above structure will be described in detail with reference to FIG. 4 . In addition, FIG. 5 is a schematic diagram showing another ...

Embodiment 3

[0053] Fig. 5 (a) is a perspective view showing another embodiment of the valve part constituting the vacuum evaporation machine of the present invention; Fig. 5 (b), (c) is a B-B line view sectional view of Fig. 5 (a), and Indicates the operating status of the valve parts.

[0054]As shown in FIG. 5 , the valve member 21B includes at least a cuboid-shaped stopper member 41 having the length of the vapor-deposited region in the plate width direction L of the glass substrate 12 , and a cylindrical stopper member 41 provided inside the stopper member 41 in the longitudinal direction. The space portion of the cylindrical shape and the plurality of cylindrical shaft members 42 fitted in the cylindrical space portion. In the stopper member 41, an inlet hole 43 and an outlet hole 44 are formed at opposite positions, and when the communication hole 45 formed in the shaft member is arranged at a predetermined position, as shown in FIG. 5(b), for example, the communication hole 45 can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com