A kind of organic functional thin film/ultra thin film and its preparation method and application

A technology of organic functional materials and ultra-thin films, applied in the field of organic functional material films, can solve the problems of material waste, small roughness, poor film uniformity, etc., achieve wide application prospects, achieve precise control, and easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Preparation of pretreated substrate

[0038] Si / SiO 2 The sheet was ultrasonically cleaned with water, acetone, isopropanol, etc., and then treated with oxygen plasma. The treatment conditions included: the time was 200s, the power was 100W, and the pretreated Si / SiO with a static contact angle of 2° was obtained. 2 piece.

[0039] (2) Preparation of gas source

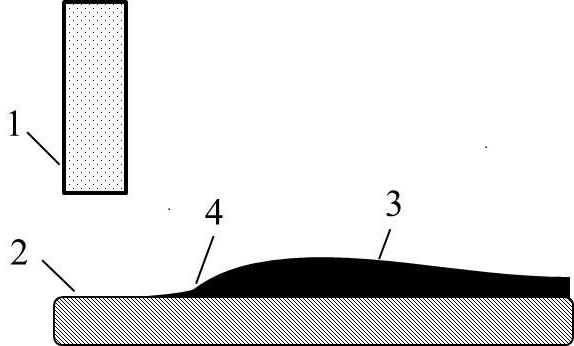

[0040] Select 30 spotting capillaries of 0.3mm×0.3mm and arrange them closely into a capillary array (such as figure 1 shown), control the gas source and pretreatment Si / SiO 2 The angle of the sheet is 90°, the height is 0.5mm, and saturated absolute ethanol is sucked into the air source.

[0041] (3) Preparation of organic functional thin films

[0042] Prepare an ethanol / water solution of poly(3,4-ethylenedioxythiophene) polystyrene sulfonate (PEDOT:PSS), the mass concentration of PEDOT:PSS is 1.1%, and the mass content of ethanol in the solvent accounts for 20%; then Use a micro-syringe to draw 20 ...

Embodiment 2

[0046] (1) Preparation of pretreated substrate

[0047] The glass sheet is ultrasonically cleaned with water, acetone, isopropanol, etc., and then treated with oxygen plasma. The treatment conditions include: the time is 200s, the power is 100W, and the pretreated glass sheet with a static contact angle of 2° is obtained.

[0048] (2) Preparation of gas source

[0049] Select an area of 1*1cm 2 The filter paper is the surface air source, the angle between the air source and the pretreated glass piece is controlled to be 60°, the height is 0.5mm, and saturated isopropanol is sucked into the air source.

[0050] (3) Preparation of organic functional thin films

[0051] Prepare PEDOT:PSS ethanol / water solution, the mass concentration of PEDOT:PSS is 1.1%, and the mass content of ethanol in the solvent accounts for 20%; then use a micro-syringe to draw 20μl PEDOT:PSS solution dropwise to 1*2cm Step 1) Prepared At the center of the pretreated glass sheet, let the droplet diffu...

Embodiment 3

[0055] (1) Preparation of pretreated substrate

[0056] Si / SiO 2 The sheet was ultrasonically cleaned with water, acetone, isopropanol, etc., and then treated with oxygen plasma. The treatment conditions included: the time was 200s, the power was 100W, and the pretreated Si / SiO with a static contact angle of 2° was obtained. 2 piece.

[0057] (2) Preparation of gas source

[0058] Select 30 spotting capillaries of 0.3mm×0.3mm and arrange them closely into a capillary array (such as figure 1 shown), control the gas source and pretreatment Si / SiO 2 The angle of the sheet is 90°, the height is 0.5mm, and saturated absolute ethanol is sucked into the air source.

[0059] (3) Preparation of organic functional thin films

[0060] Prepare an aqueous solution of MESO-tetrakis(4-sulfonylphenyl)porphine manganese chloride (MnTPPS), the mass concentration of MnTPPS is 1.0%; 2 Step 1) Prepared pretreated Si / SiO 2 At the center of the sheet, let the droplet spread to form a uniform ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com