OLED evaporation crucible

A crucible and evaporation technology, applied in vacuum evaporation coating, sputtering coating, ion implantation coating and other directions, can solve the problem of blocking the nozzle, save heat consumption, avoid condensation and block the nozzle, and the structure is simple. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

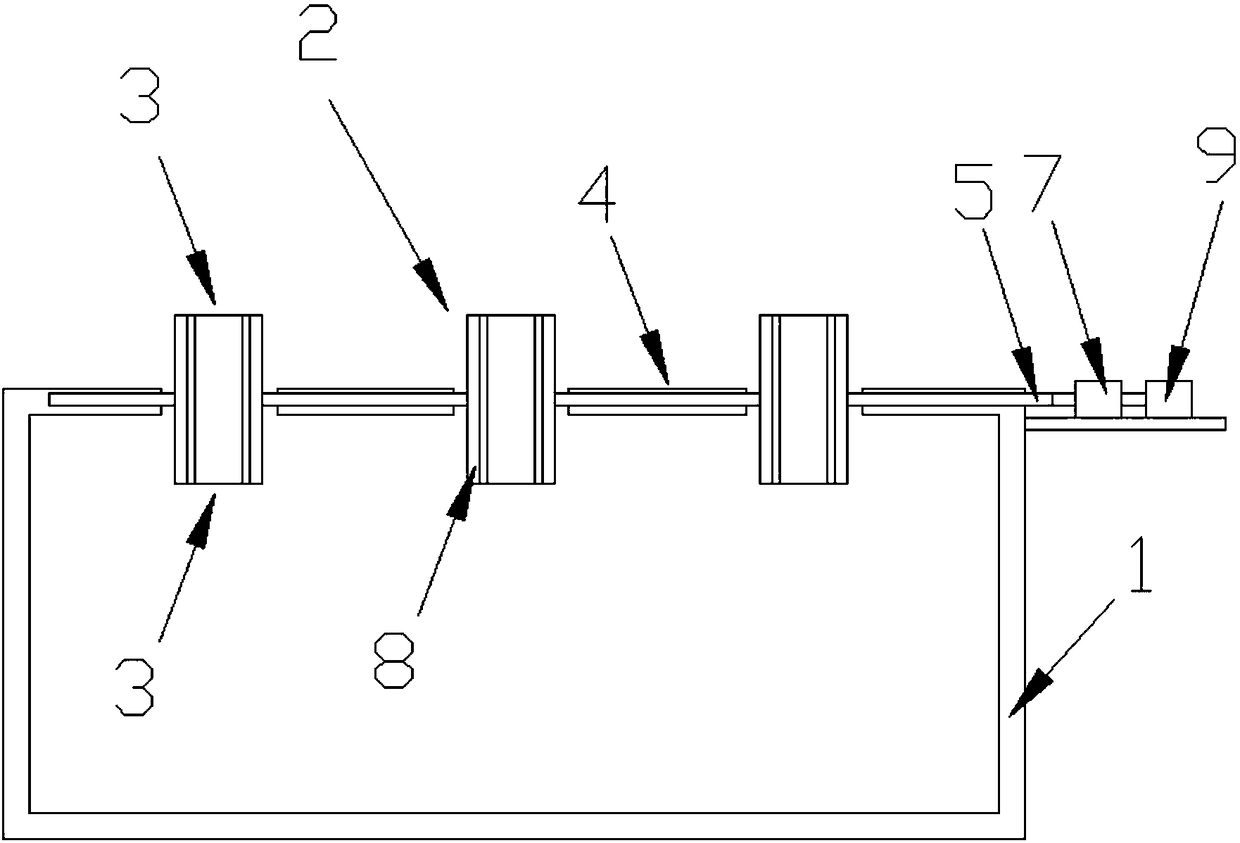

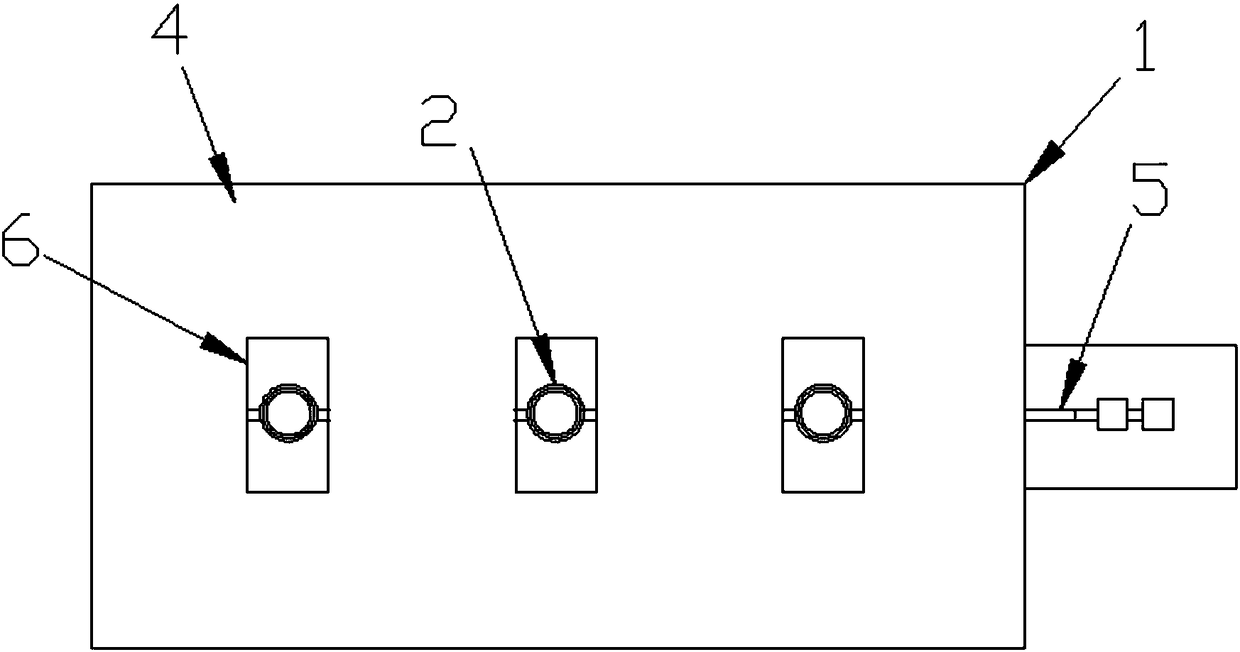

[0023] Such as figure 1 , figure 2 As shown, the present invention is an OLED evaporation crucible, including a crucible body 1 and an evaporation vapor ejection structure 2 provided on the crucible body 1, and the evaporation vapor ejection structure 2 includes a spout 3 for ejection or overflow of the evaporation vapor , The vapor deposition steam ejection structure 2 is provided with an anti-spout clogging mechanism. The evaporation steam ejection structure 2 is a tubular nozzle, and the nozzle 3 is the two ports of the nozzle. The anti-spout blocking mechanism includes a rotating shaft 5 that is installed in the top plate 4 of the crucible body 1, and several nozzles are fixedly connected to the rotating shaft 5, adjacent to each other. The nozzles are arranged at intervals, all the nozzles are placed at the same position on the rotating shaft 5, the axis of the rotating shaft 5 is set perpendicular to the axis of the nozzle, the rotating shaft 5 is fixedly connected to ...

Embodiment 2

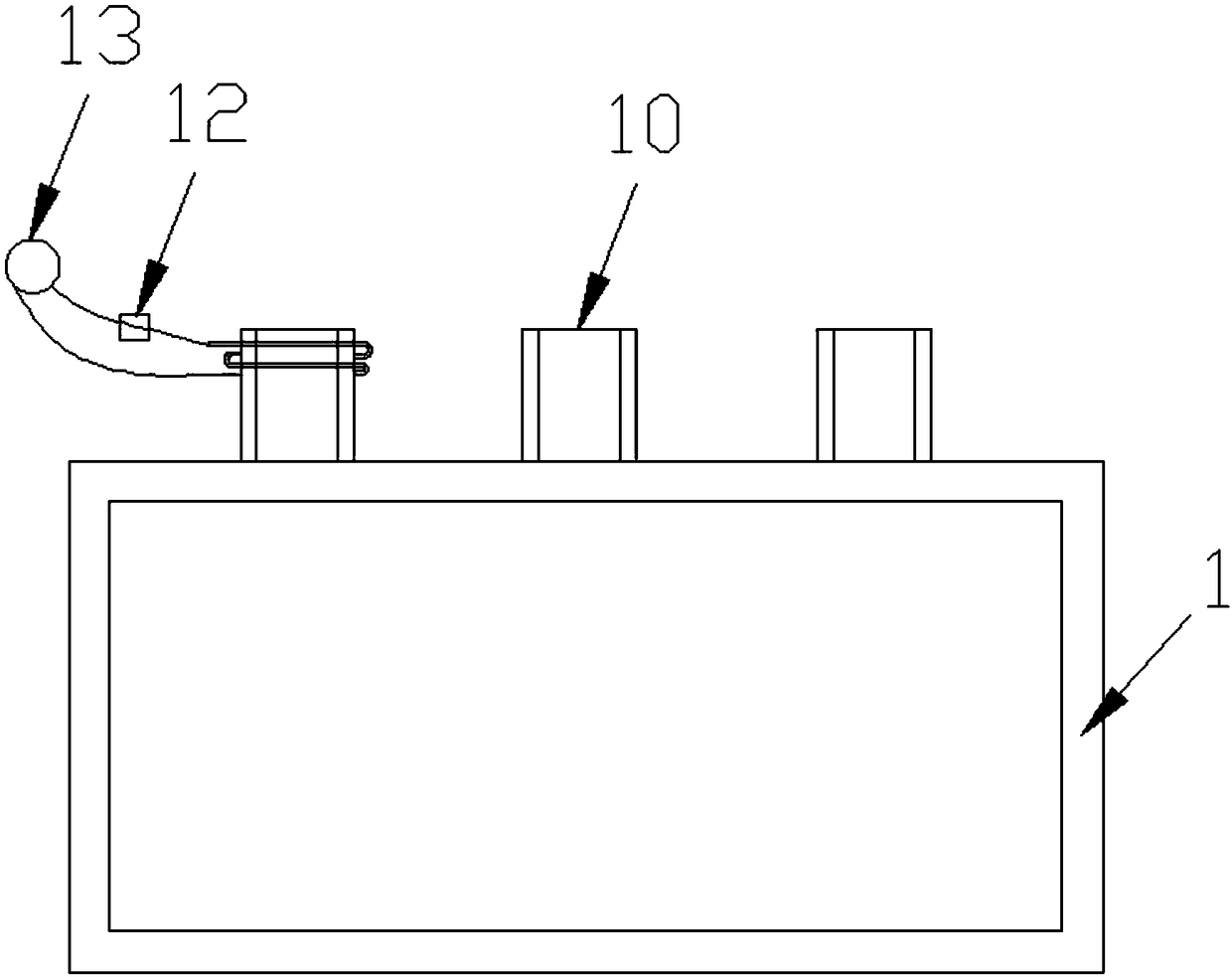

[0025] The difference from Embodiment 1 is that, as image 3 , Figure 4 shown (for ease of illustration, image 3 Not all coils are shown), the vapor deposition steam ejection structure 2 is a steel pipe 10 fixedly connected to the top plate 4 of the crucible body 1, one end of the steel pipe 10 communicates with the inner cavity of the crucible body 1, and the other end is ejected or overflowed as vapor deposition steam A coil 11 is wound around the outer peripheral surface of the steel pipe 10, and the coil 11 is connected to a power source 13 through a voltage regulator 12. The coil 11 is covered with a magnetic and heat insulating layer 14. Several steel pipes 10 are provided to form multiple spouts 3, the steel pipe 10 located in the middle of the crucible body 1 is a straight pipe, and the remaining steel pipes 10 are bent pipes.

Embodiment 3

[0027] The difference from Embodiment 1 is that, as Figure 5 to Figure 8 shown (for ease of illustration, Figure 5 The through hole 16 and the electromagnet 20 are not shown; Figure 6 The side plate of the crucible body is not shown), the vapor deposition steam ejection structure includes a spout for ejection or overflow of the vapor deposition vapor, and the vapor deposition vapor ejection structure includes a cover hole that is rotatably arranged on the lower surface of the top plate 4 of the crucible body Plate 15, the hole-shielding plate 15 is a rectangular plate, the top plate 4 on the crucible body is a rectangular plate with a size larger than the hole-shielding plate 15, the nozzle is a through hole 16 arranged on the top plate 4 on the crucible body, and a corner of the hole-shielding plate 15 is set through The lower surface of the upper top plate 4 of the crucible body is fixedly provided with a shaft 17 adapted to the aforementioned hole, and the hole-shieldin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com