Webbing loom weaving control mechanism

A technology of control mechanism and ribbon loom, which is applied to looms, small looms, fabrics, etc., to achieve the effects of quick adjustment, easy operation, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

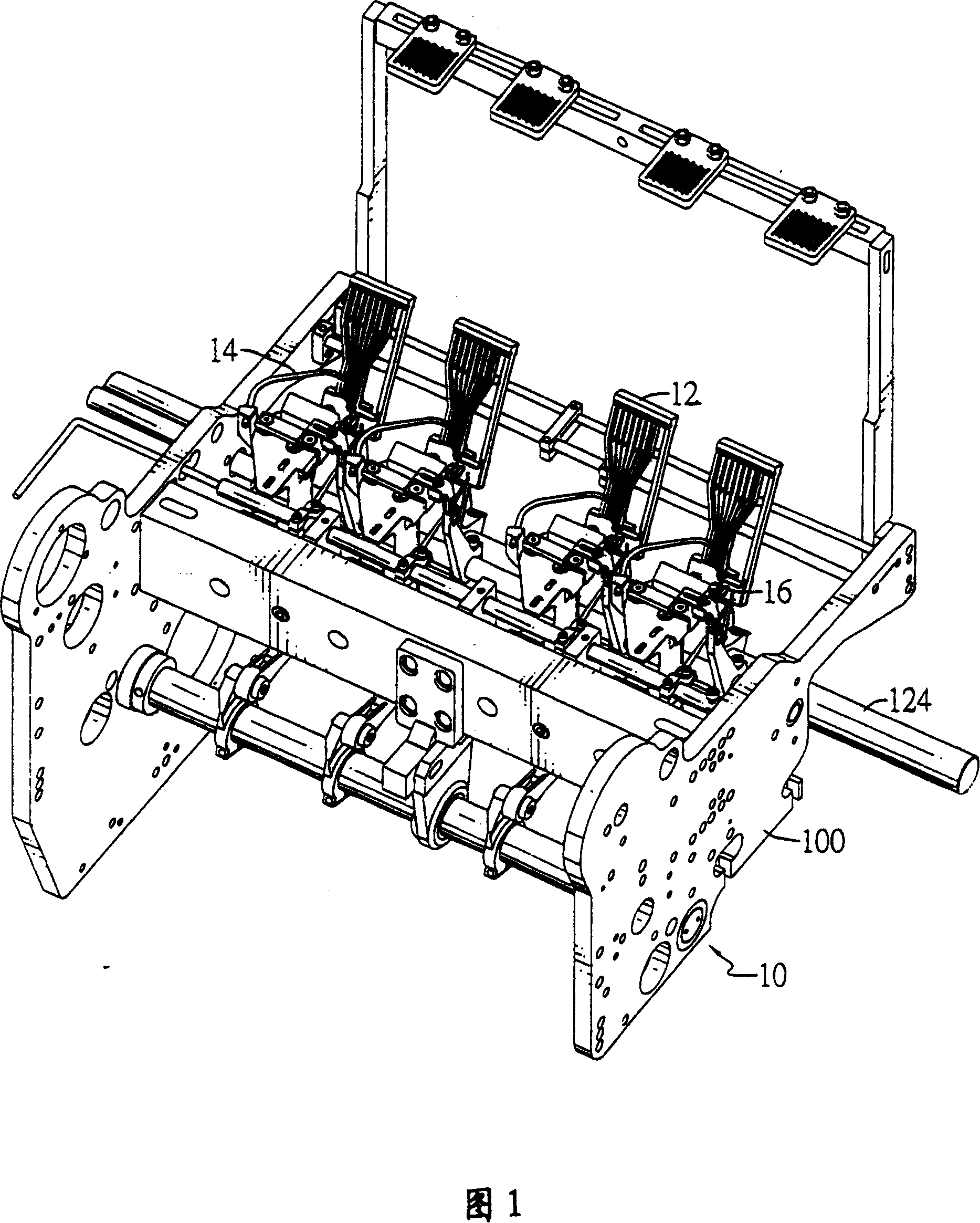

[0027] As shown in FIG. 1 , the present invention is assembled on a ribbon loom with four steel reeds 12 , and the four steel reeds are assembled on a frame 10 .

[0028] Each reed 12 promptly represents one group of weaving mechanisms, that is, the ribbon loom has four groups of weaving mechanisms, and can simultaneously carry out the weaving operation of four wide and narrow belts. Each group of weaving mechanisms is respectively provided with a weft hook 14 and a weft hook 16, which are indispensable components in the weaving mechanism of the ribbon loom.

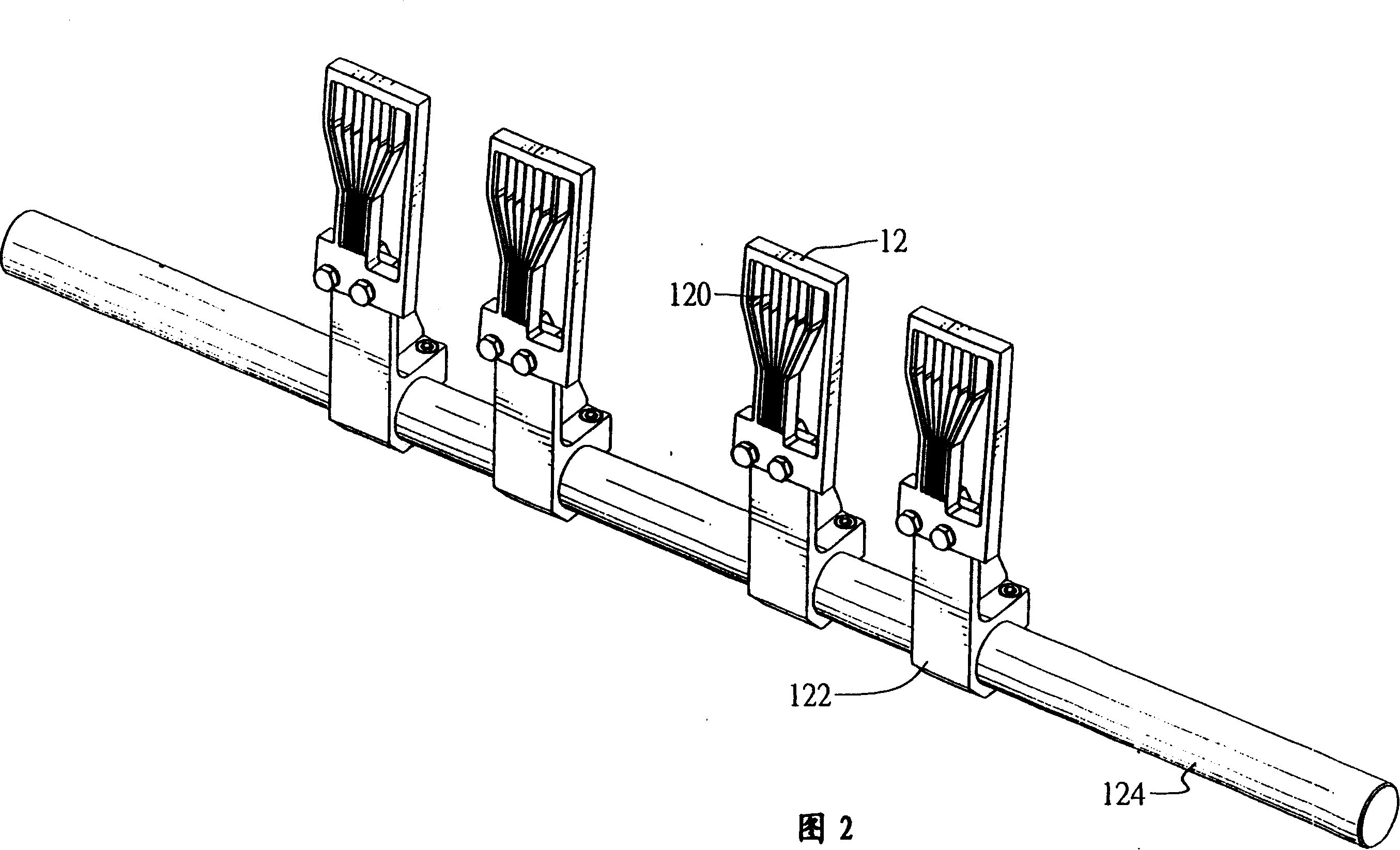

[0029] Because the ribbon loom controls the spacing of the warp threads by the variation of the steel reed 12 position when carrying out wide and narrow band weaving. As shown in Figure 2, all have in the reed 12 by wide narrowing interval seam 120, and the warp thread of loom is passed in the interval seam 120 of steel reed 12, thereby can be opposite in steel reed 12. By changing the relative height of the warp yarns,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com