Surface micromachining process for resin mold

A resin mold and machining technology, which is applied in the field of surface micromachining, can solve the problems that resin molds cannot be micromachined, resin molds cannot be micromachined, and cannot be engraved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Hereinafter, embodiments of the present invention will be described with reference to the drawings. It is to be noted that, before describing the surface micromachining method for the resin mold, the production method of the resin mold which is a premise of the surface micromachining method will be described first.

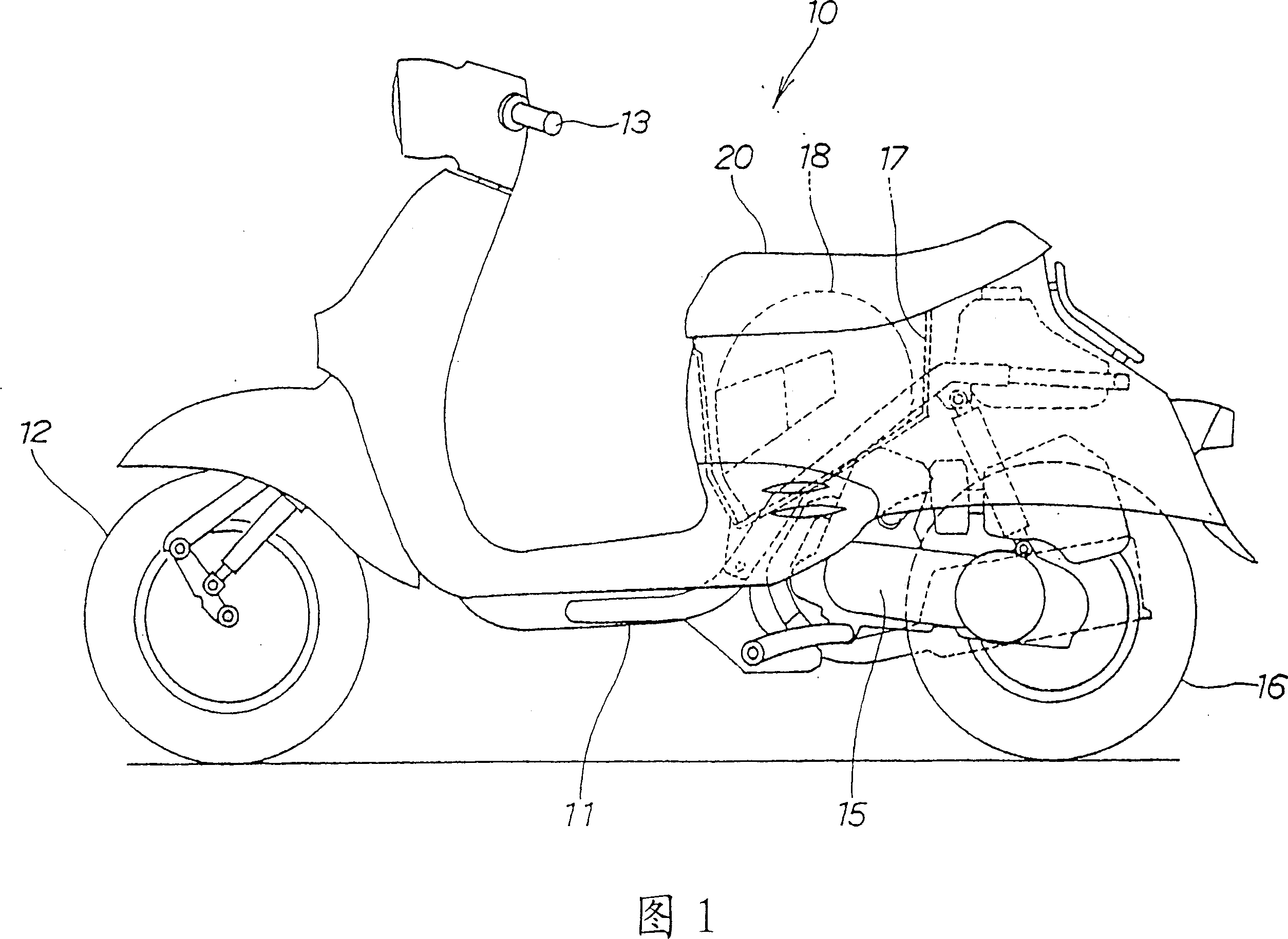

[0040] Fig. 1 is a side view of a small motorcycle to which the present invention is applied. The scooter 10 is a vehicle including a frame 11 . A front wheel 12 and a handle 13 are provided at the front of the vehicle frame 11 . The rear wheel 16 is arranged on the rear portion of the vehicle frame 11 through the swing type power unit 15 . The trunk 17 and the vehicle seat 20 are disposed adjacently above the rear wheels 16 . The trunk 17 is a large-sized case that can accommodate a helmet 18 that is put into or taken out of the trunk 17 by opening the seat 20 .

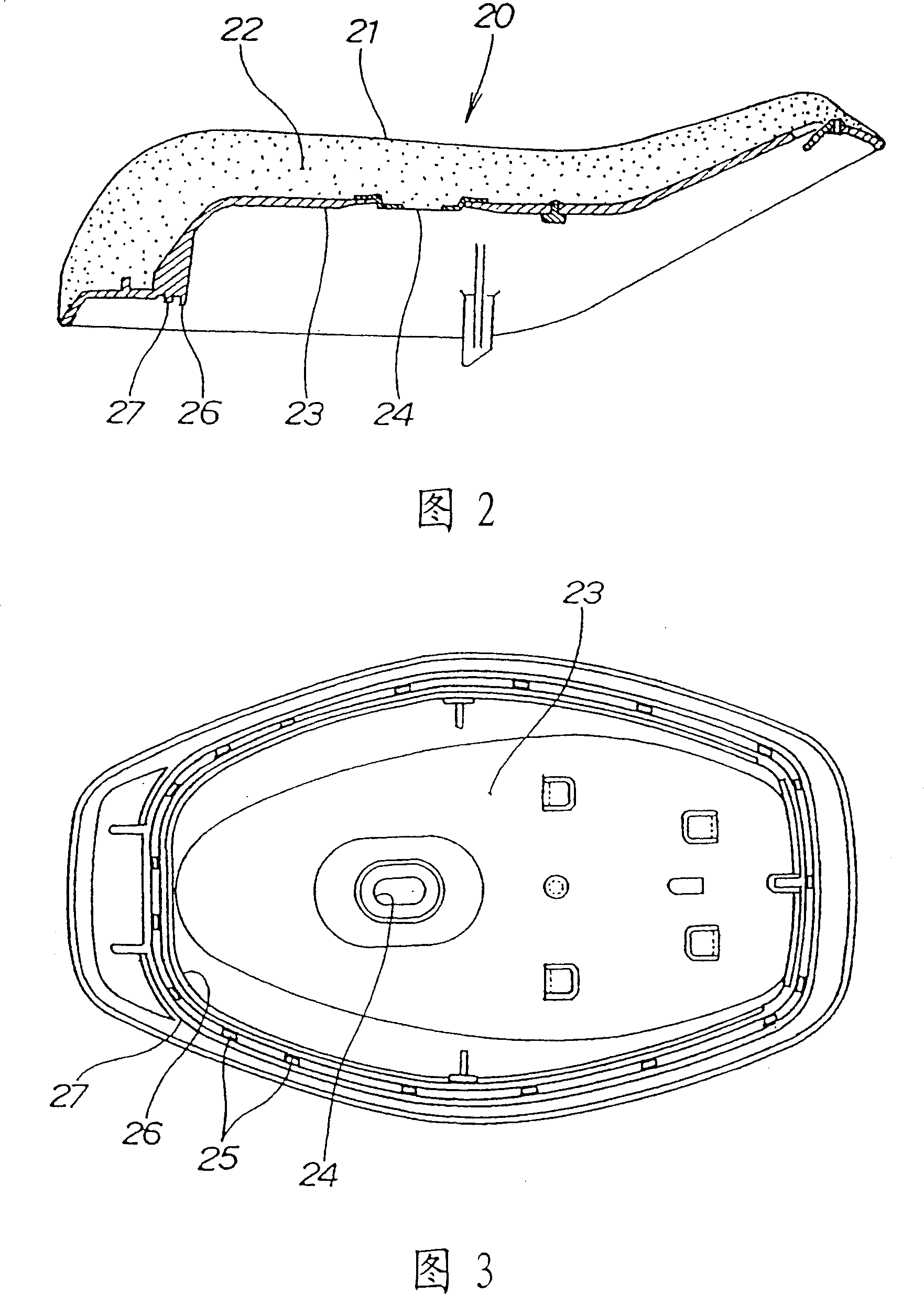

[0041] Fig. 2 is a sectional view of a vehicle seat to which the present invention is app...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com