Short deposition distance image on-line iron spectral apparatus and method

A technology of distance image and ferrography, which is applied in the field of short deposition distance image-type online ferrography device, can solve the problems that cannot reflect the surface morphology of abrasive grains, and achieve the effect of reducing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

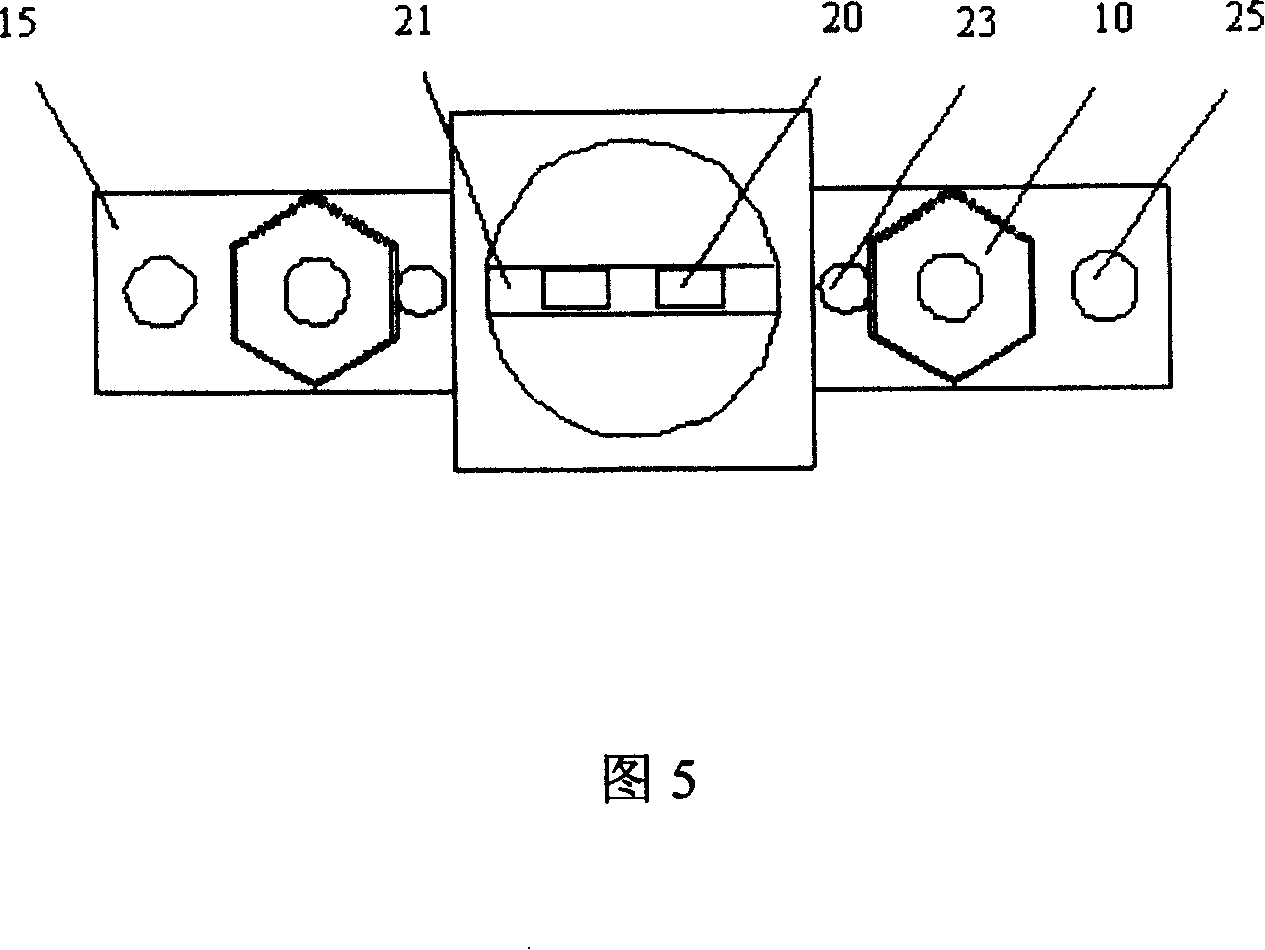

[0018] Accompanying drawing is the specific embodiment of the present invention;

[0019] Below in conjunction with accompanying drawing, content of the present invention is described in further detail:

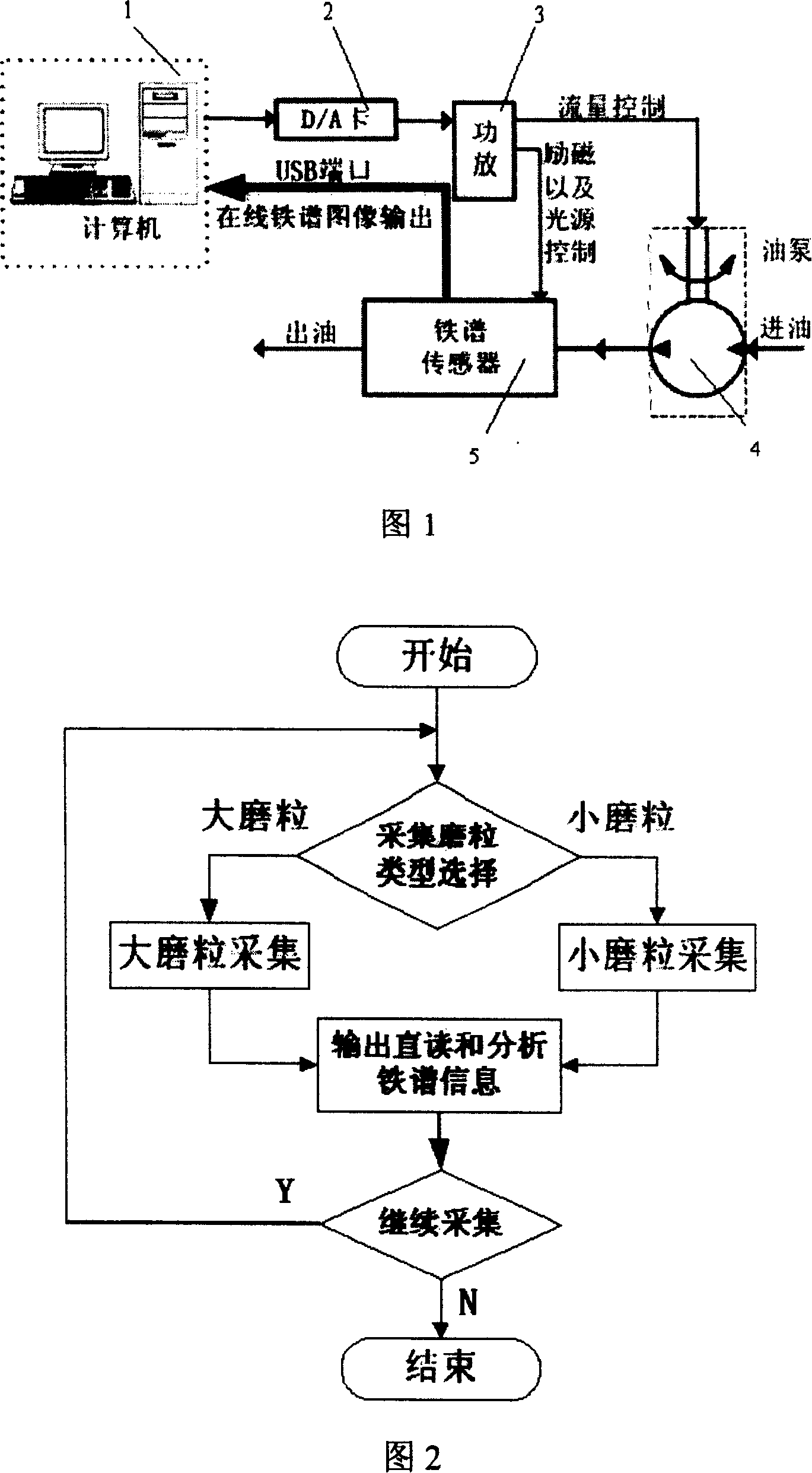

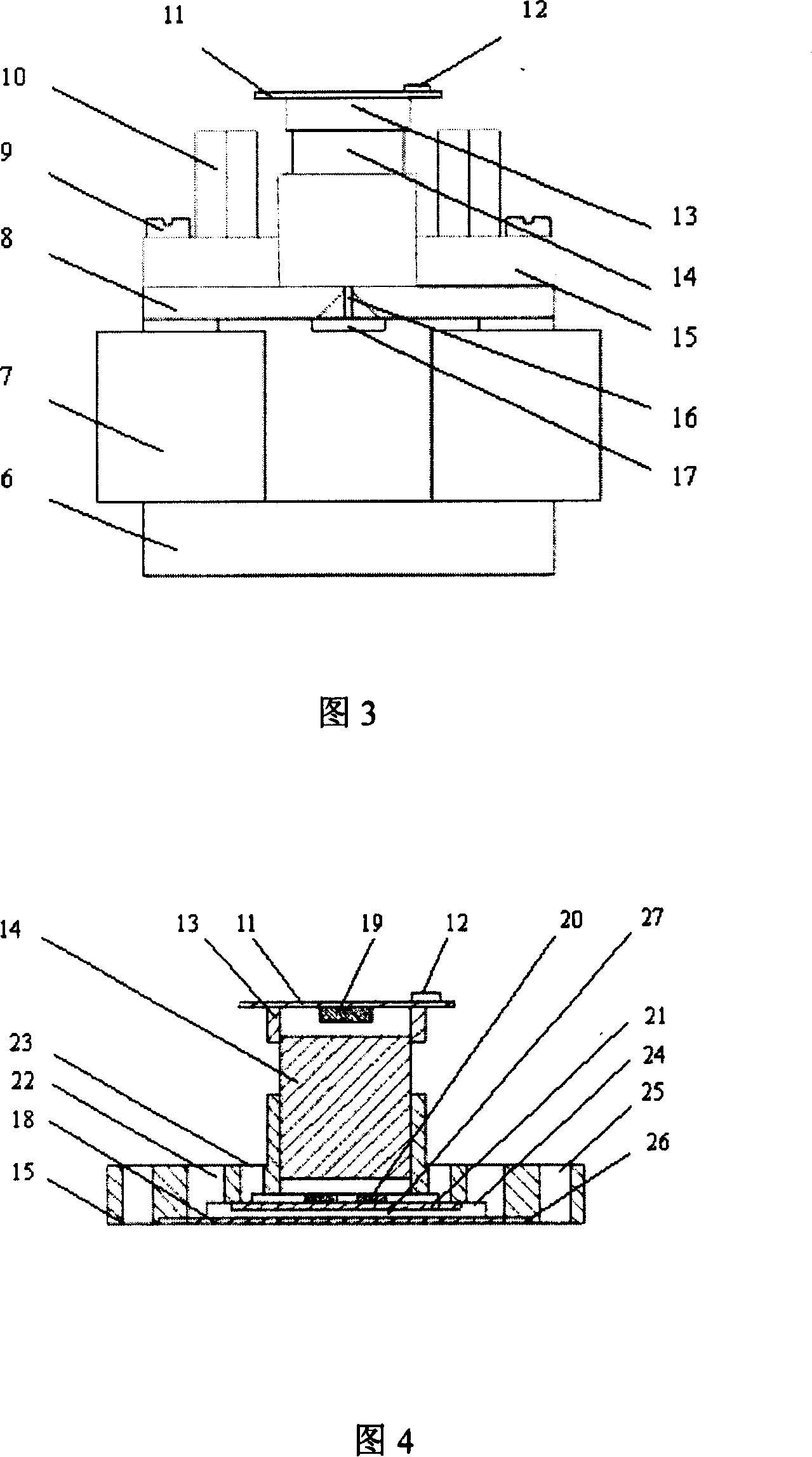

[0020] With reference to shown in Fig. 1, the structural principle and working principle of the device of the present invention are: the present invention comprises computer 1, D / A card 2, power amplifier 3 and oil pump 4, and computer 1 controls the output of power amplifier 3 by D / A card 2, power amplifier 3 is connected to the ferrographic sensor 5 to control the excitation and light source. At the same time, the computer 1 is connected to the oil pump 4 through the D / A card 2 and the power amplifier 3 to control the flow of the oil pump 4. In this way, under the control of the computer 1, by adjusting the strength of the working magnetic field and the flow rate of the oil, the separate deposition of large and small abrasive particles in the same area can be realized, inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com