Method for deciding margin of single line blade of axial flow compressor

An axial flow compressor, compressor technology, applied in pump control, mechanical equipment, machine/engine, etc., to achieve the effect of easy application and intuitive understanding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

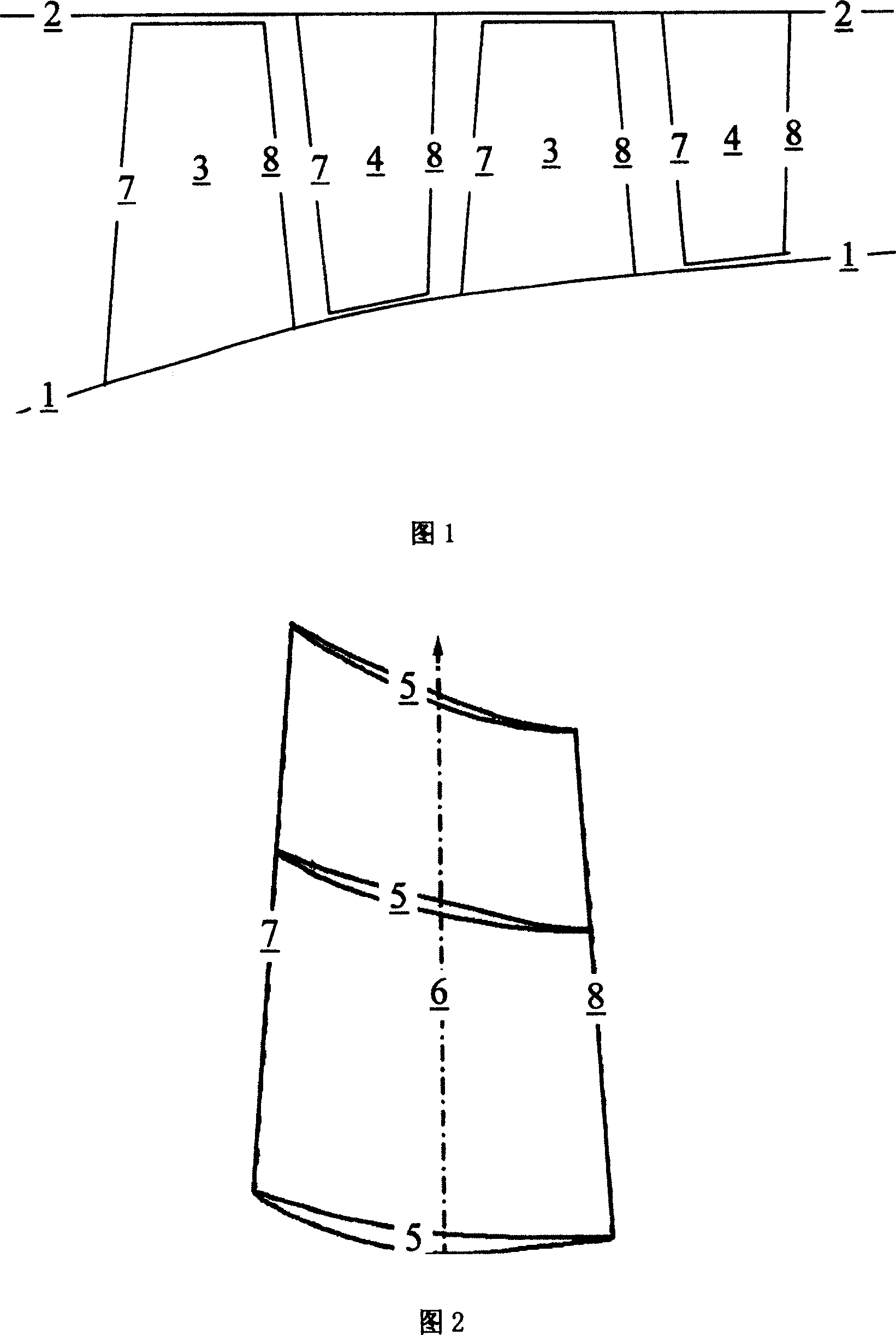

[0028] For a compressor blade, the process of designing to achieve the margin target includes the following steps:

[0029] 1) Interpret the succession of each section of the blade to reach the stall directly from the calculation results of the three-dimensional flow field;

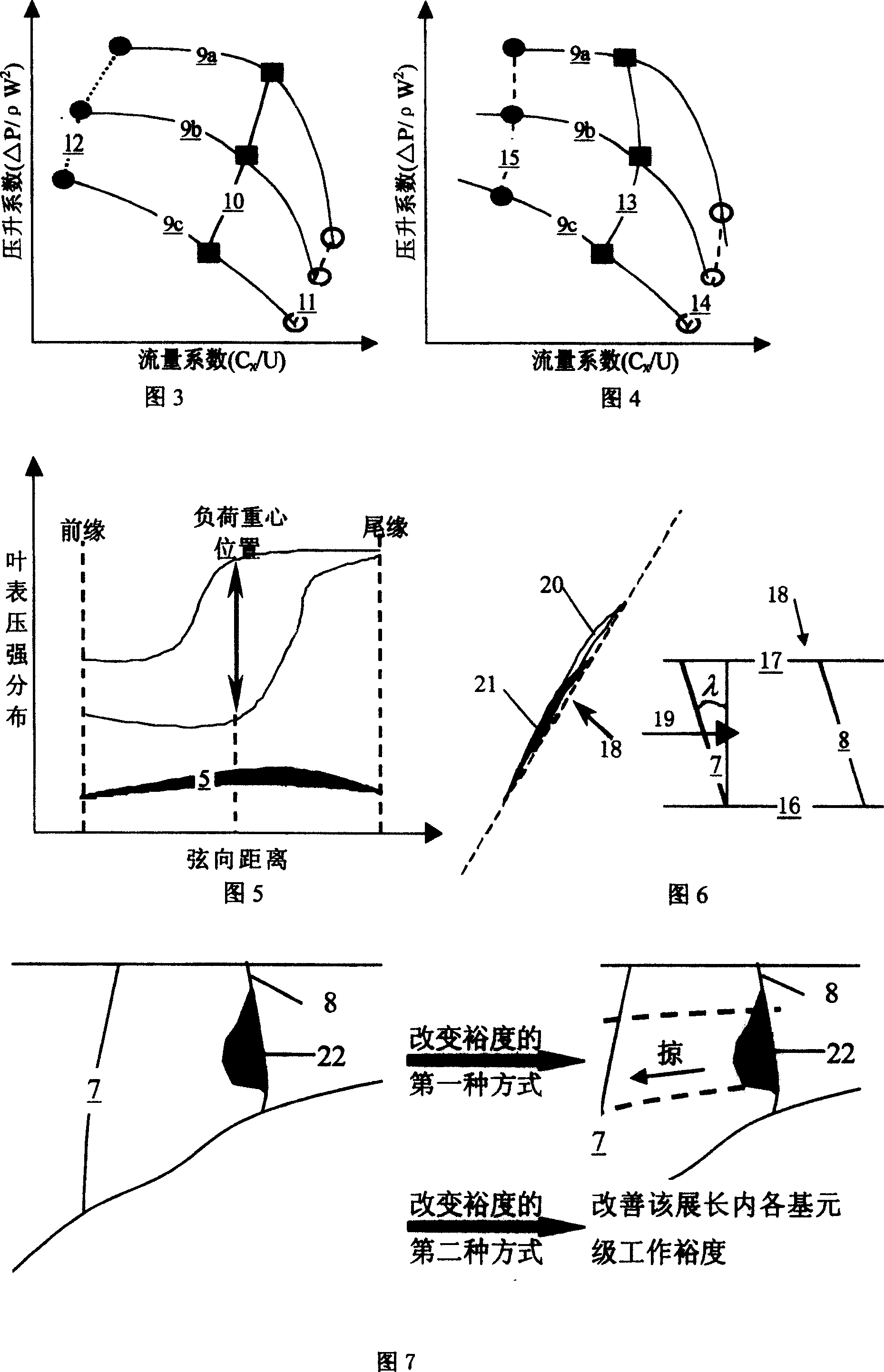

[0030] 2) The flow-load characteristics of each section are drawn in the same figure; according to the full three-dimensional flow calculation results of the entire blade design condition, the positions of the design points on the flow-load characteristic line of each section shown in Figure 3 are determined, and are shown in Figure 3 4, namely shown in curve 13 among Fig. 4;

[0031] 3) Calculate the entire blade to the near-stall point by using the full three-dimensional flow field, and then determine the actual positions of the operating points of each section of the entire blade at the near-stall point, as shown in the points on the curve 15 in Figure 4;

[0032] 4) As shown in Figure 7, it represent...

Embodiment 2

[0038] For a compressor blade, the process of designing to achieve the margin target includes the following steps:

[0039]1) The compressor blades are regarded as an infinite number of small compressors with infinitely small heights matched in the span direction, and each small compressor has a corresponding flow-load characteristic line, as shown in the curves 9a, 9b, and Shown in 9c; the maximum flow state corresponds to the point on the line 11 (dotted line 11 in Fig. 3) of the near blockage condition, and the right end of each flow-load characteristic line in Fig. 3 is represented by a hollow circle; the minimum flow state corresponds to the point near On the stall condition line 12 (dotted line 12 in Fig. 3), the left end of each flow-load characteristic line in Fig. 3 is represented by a solid circle; a certain intermediate flow point corresponds to the design condition line 10 (in Fig. Solid line 10), in Fig. 3, represent with the solid rectangular box on each flow-loa...

Embodiment 3

[0047] For a compressor blade, the process of designing to achieve the margin target includes the following steps:

[0048] 1) Interpret the succession of each section of the blade to reach the stall directly from the results of the three-dimensional calculation of the fluid;

[0049] 2) The flow-load characteristics of each section are drawn in the same figure. According to the full three-dimensional flow calculation results of the entire blade design condition, the positions of the design points on the flow-load characteristic line of each section shown in Fig. 3 are determined, and are shown in Fig. 4, as shown in curve 13 in Fig. 4;

[0050] 3) The entire blade is calculated to the near-stall point by using full three-dimensional flow calculation, and then the actual position of each cross-section operating point of the entire blade is determined when the entire blade is near the stall point, as shown in the point on the curve 15 in Figure 4;

[0051] 4) As shown in Figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com