A special reversible temperature-indicating and light-stabilizing coating for transformer pile heads and its preparation method

A technology of transformer and light stabilization, applied in the field of paint manufacturing, can solve the problems of increased risk and high labor cost, and achieve the effects of excellent performance, good manufacturability and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

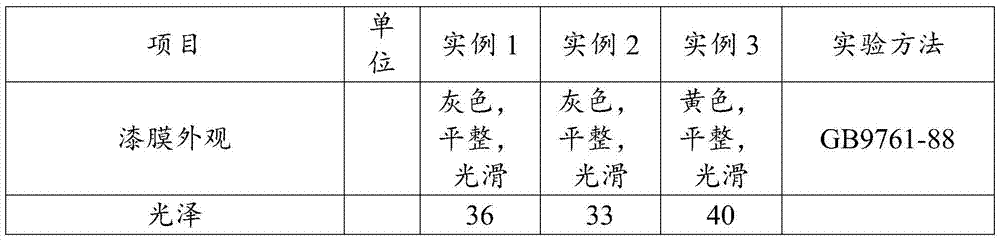

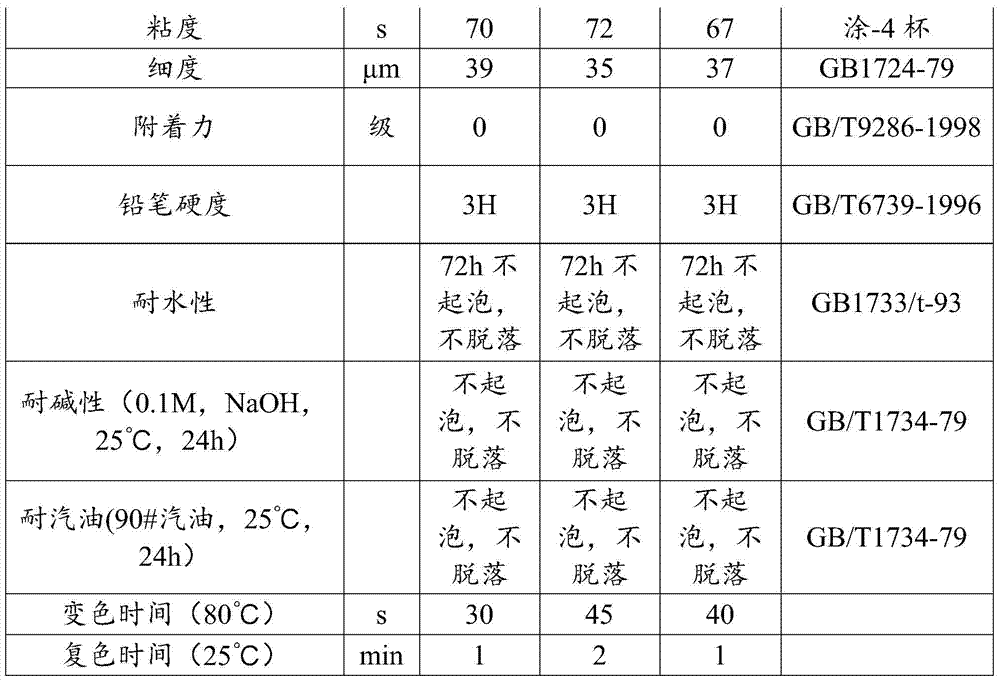

Examples

Embodiment 1

[0034] The invention provides a special reversible temperature-indicating and light-stabilizing coating for transformer pile heads and a preparation method thereof, comprising the following steps:

[0035] 1) Mix 200g epoxy resin, 20g dispersant (EFKA 4310), 4g defoamer (Deform 5300), 8g anti-sedimentation agent (organic bentonite, absolute ethanol, xylene mixture), 8g leveling agent (D201) , 20g of solvent (xylene) was mixed and added into the beaker, then stirred, the stirring speed was 600r / min, and pre-dispersed for 60min to obtain the pre-dispersed mixture;

[0036] 2) Put 80g of temperature-sensitive powder, 20g of sericite powder, 20g of magnesium aluminum silicate, 20g of UV absorber (2-hydroxy-4-n-octyloxybenzophenone) and the pre-dispersed mixture into the grinder , after adding glass beads, grind, pass through the condenser, adjust the outlet temperature to 40°C, adjust the speed to 2500r / min, measure the fineness every 30min, grind until the fineness reaches below ...

Embodiment 2

[0040] The invention provides a special reversible temperature-indicating and light-stabilizing coating for transformer pile heads and a preparation method thereof, comprising the following steps:

[0041] 1) Mix 200g epoxy resin, 20g dispersant (Tego Dispers 715W), 4g defoamer (Deform 5300), 8g anti-settling agent (a mixture of organic bentonite, absolute ethanol, xylene), 8g leveling agent (D201 ) and 20g solvent (xylene) were mixed and added into the beaker, then stirred, the stirring speed was 600r / min, and pre-dispersed for 60min to obtain the pre-dispersed mixture;

[0042] 2) Put 60g of temperature-sensitive powder, 20g of sericite powder, 20g of magnesium aluminum silicate, 8g of UV absorber (2-hydroxy-4-n-octyloxybenzophenone) and the pre-dispersed mixture into the grinder , after adding glass beads, grind, pass through the condenser, adjust the outlet temperature to 40°C, adjust the speed to 2500r / min, measure the fineness every 30min, grind until the fineness reache...

Embodiment 3

[0046] The invention provides a special reversible temperature-indicating and light-stabilizing coating for transformer pile heads and a preparation method thereof, comprising the following steps:

[0047]1) Mix 200g epoxy resin, 20g dispersant (EFKA 4310), 4g defoamer (Tego 825), 8g anti-sedimentation agent (organic bentonite, absolute ethanol, xylene mixture), 8g leveling agent (D201) Mix and add 20g of solvent (xylene) into the beaker, then stir, the stirring speed is 600r / min, carry out pre-dispersion for 60min, and obtain the pre-dispersion mixture;

[0048] 2) Put 100g of temperature-sensitive powder, 12g of sericite powder, 20g of magnesium aluminum silicate, 8g of UV absorber (2-hydroxy-4-n-octyloxybenzophenone) and the pre-dispersed mixture into the grinder , after adding glass beads, grind, pass through the condenser, adjust the outlet temperature to 40°C, adjust the speed to 2500r / min, measure the fineness every 30min, grind until the fineness reaches below 40μm, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com