System for fixing the mobile jaw of a cone or gyratory crusher

A technology of moving claws and pulverizers, applied in the system field of moving claws

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

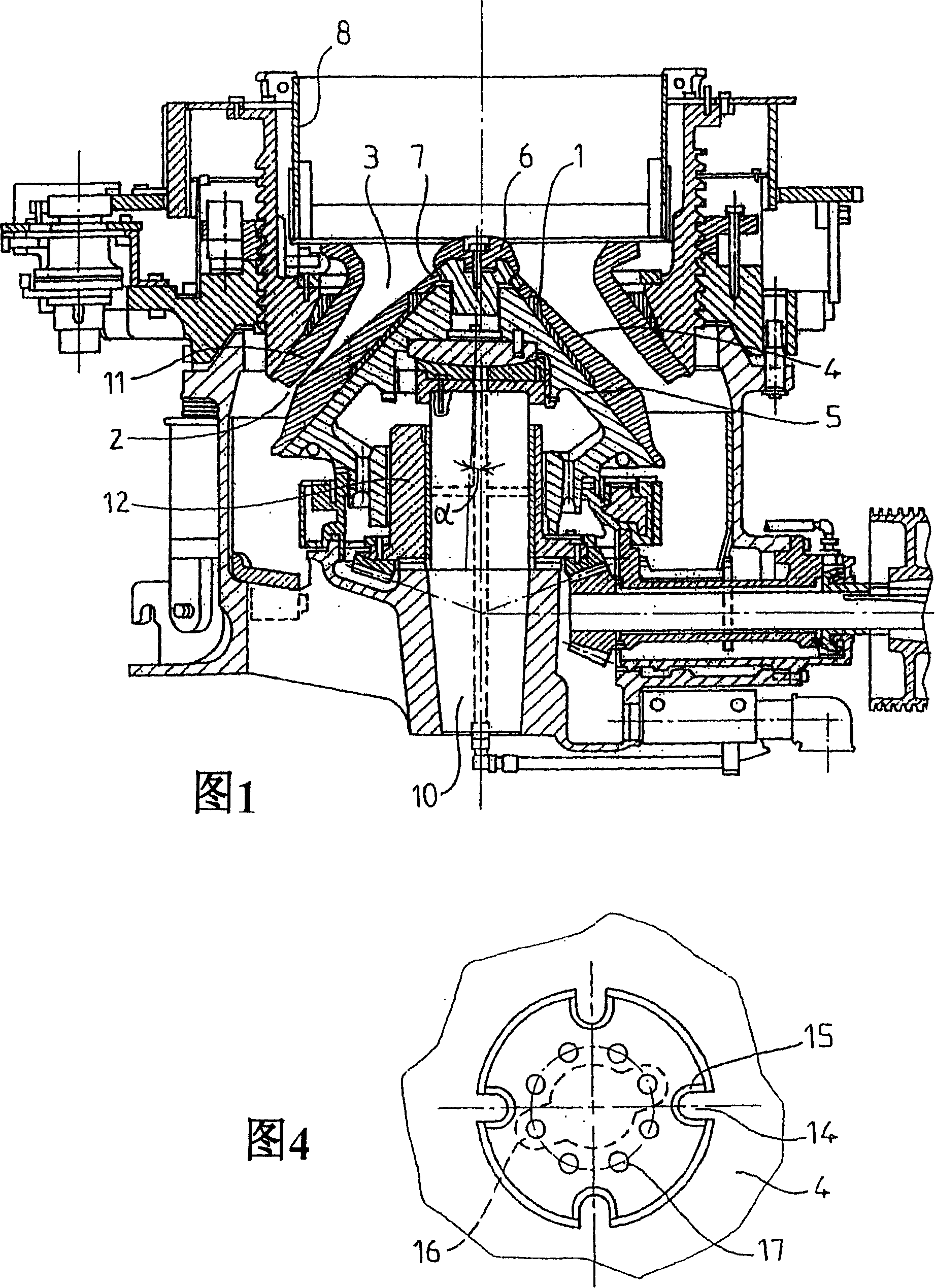

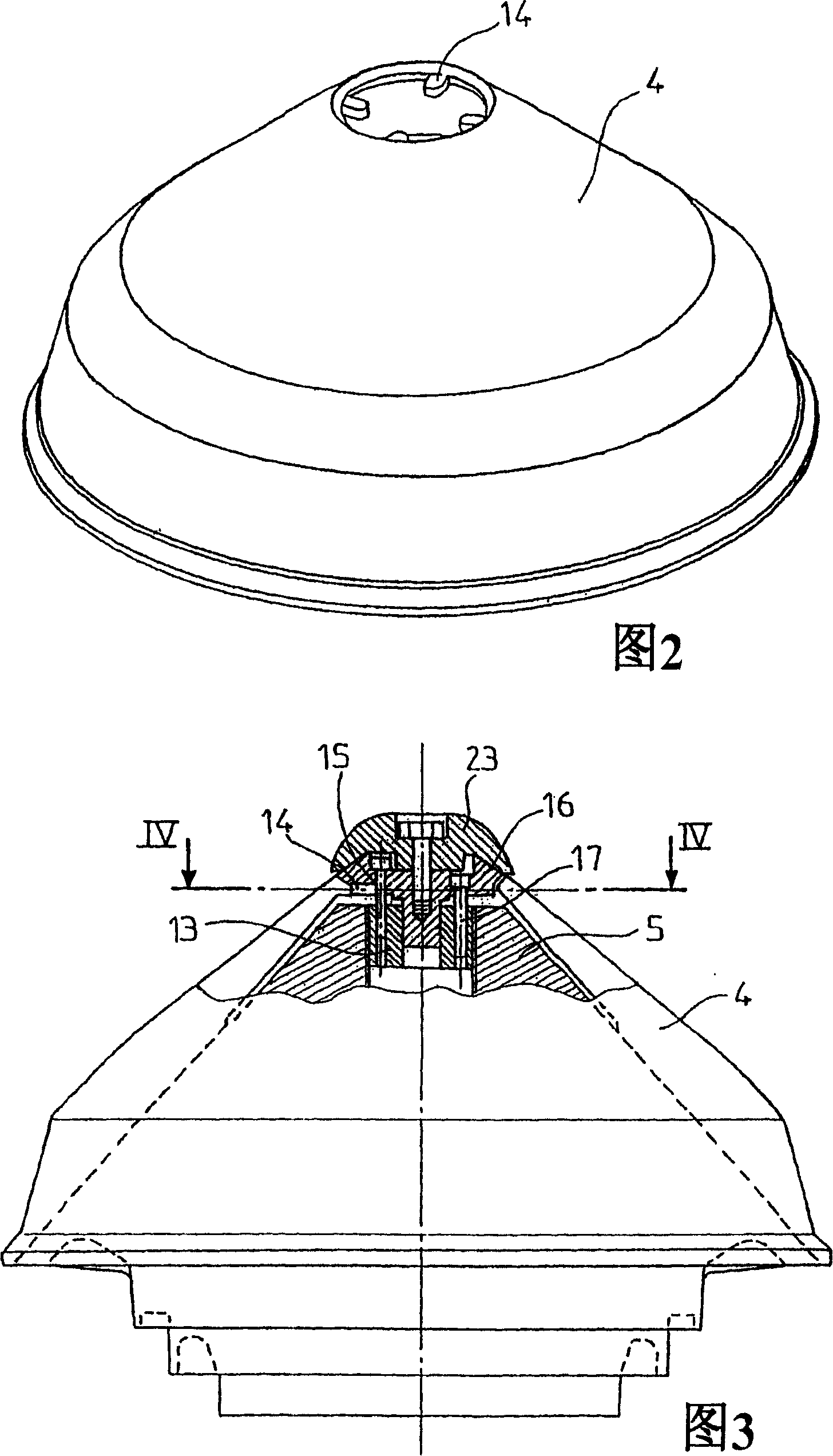

[0018] As shown in FIG. 3 , the moving jaws 4 are located on the crushing head 5 and are pressed against the lower wide part of the crushing head in a conventional manner, as shown in FIG. 1 . In this position its clamping is realized by a blocking element consisting of two parts connected by a screw: a blocking plate 16 whose diameter at its upper part is at least equal to the outer diameter of the cone formed by the jaws 4; A threaded flange 13 is fastened to said blocking plate by means of screws 17 .

[0019] A protective cover 23 for the head of the screw 17 is located on the blocking plate and is simply screwed thereon.

[0020] As described above for the prior art, during operation the rotation of the movable jaw 4 relative to the head 5 enables a self-locking clamping of the parts 16, 13, allowing a proper clamping without wearing down the jaws.

[0021] However, in operation, when the jaw 4 slides on the comminution head and essentially clamps, it also slides relativ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com