Automobile frame

A technology of automobile frame and frame, which is applied in the direction of vehicle components, substructure, transportation and packaging, etc. It can solve the problems of occupying a lot of space, increasing the self-weight of the longitudinal beam, and the difficulty of increasing the rigidity and bearing capacity of the longitudinal beam of the frame. Reduce the weight of the structure, increase the rigidity of the frame longitudinal beam, and improve the effect of rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

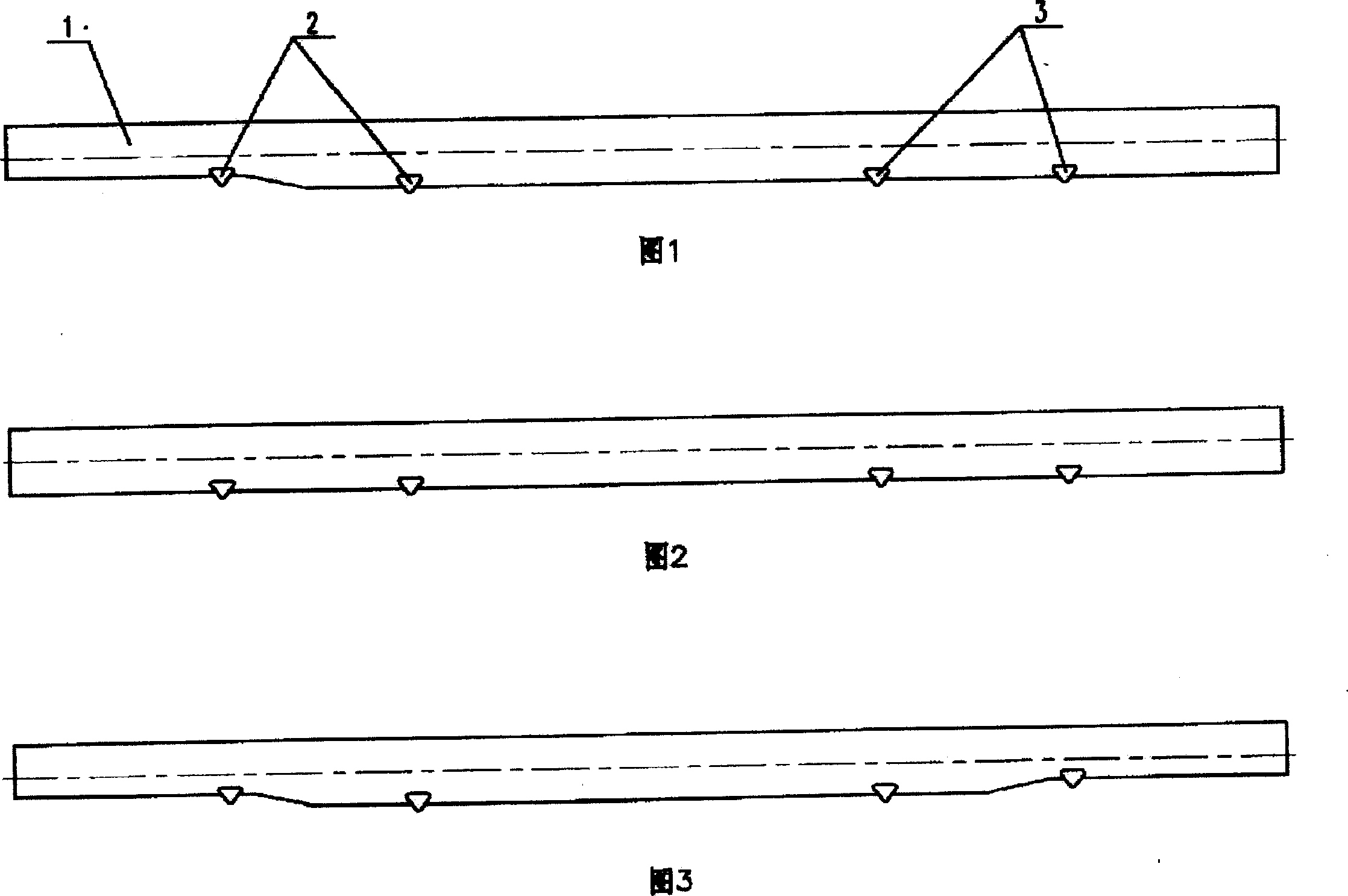

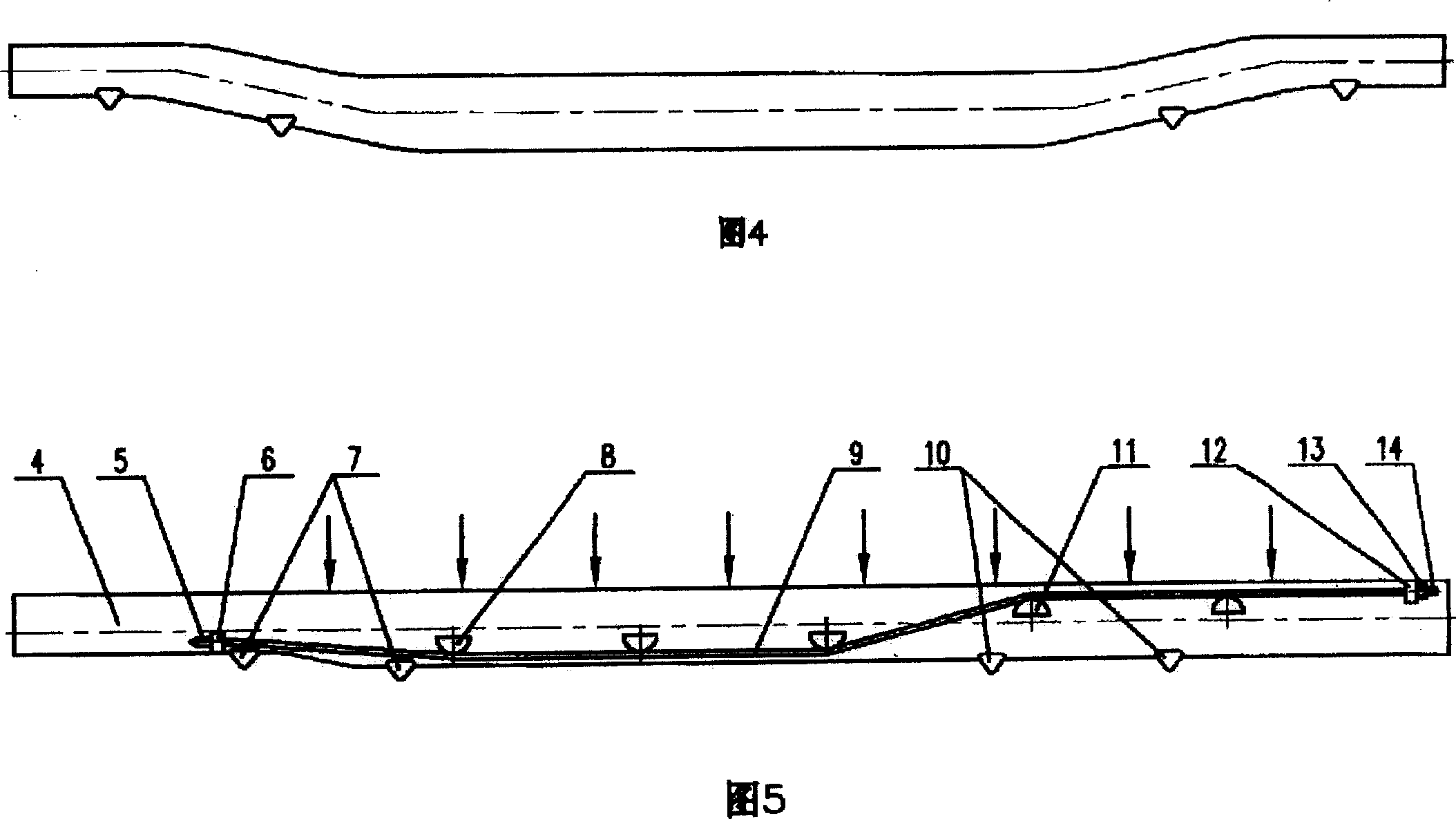

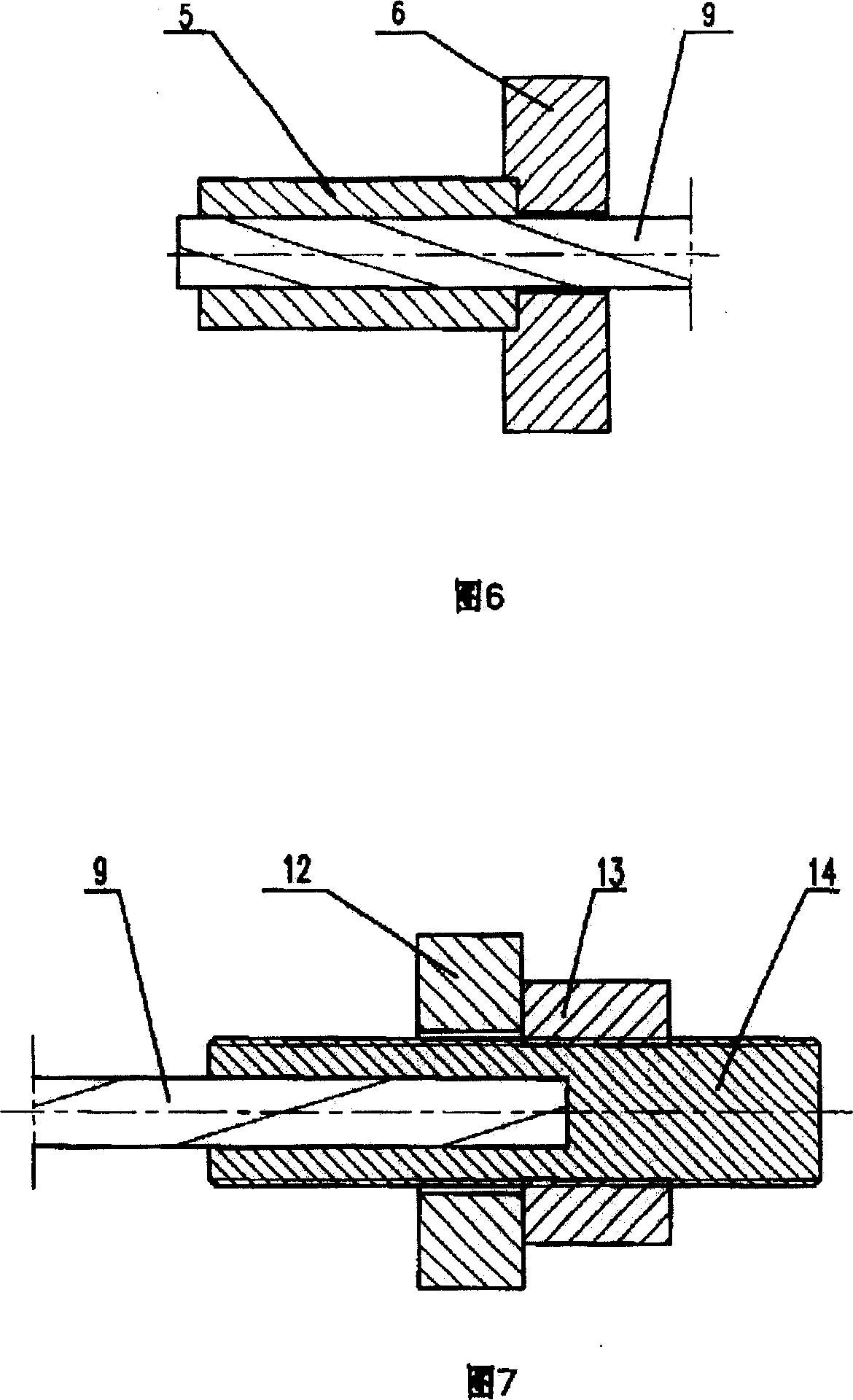

[0026] Shown in Fig. 1, in the automobile frame of prior art, front wheel support 2 and rear wheel support 3 are housed on longitudinal beam 1, the vehicle frame of this structure is under the condition of use, and the longitudinal beam 1 of vehicle frame is under self-weight And under the action of load, it will show downward deflection. The upper part of the longitudinal beam 1 before the front wheel support 2, the lower part of the longitudinal beam 1 between the front wheel support 2 and the rear wheel support 3, and the upper part of the longitudinal beam 1 behind the rear wheel support 3 bear tensile stress. The longitudinal beam structures of other vehicle frames in the prior art are not much different from this, as shown in Fig. 2, Fig. 3, and Fig. 4, only the variation of the section size and the undulation of the horizontal direction are arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com