Single number two-color wiring fluorescence label typography

A fluorescent marker and process technology, applied in printing process, printing, printing of special varieties of printed matter, etc., can solve the problems of increasing the occupation of personnel, equipment, time, space and funds, unfavorable production management, digital confusion, etc. , to achieve the effect of shortening the product production process cycle, shortening the product process cycle, and reducing capital occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

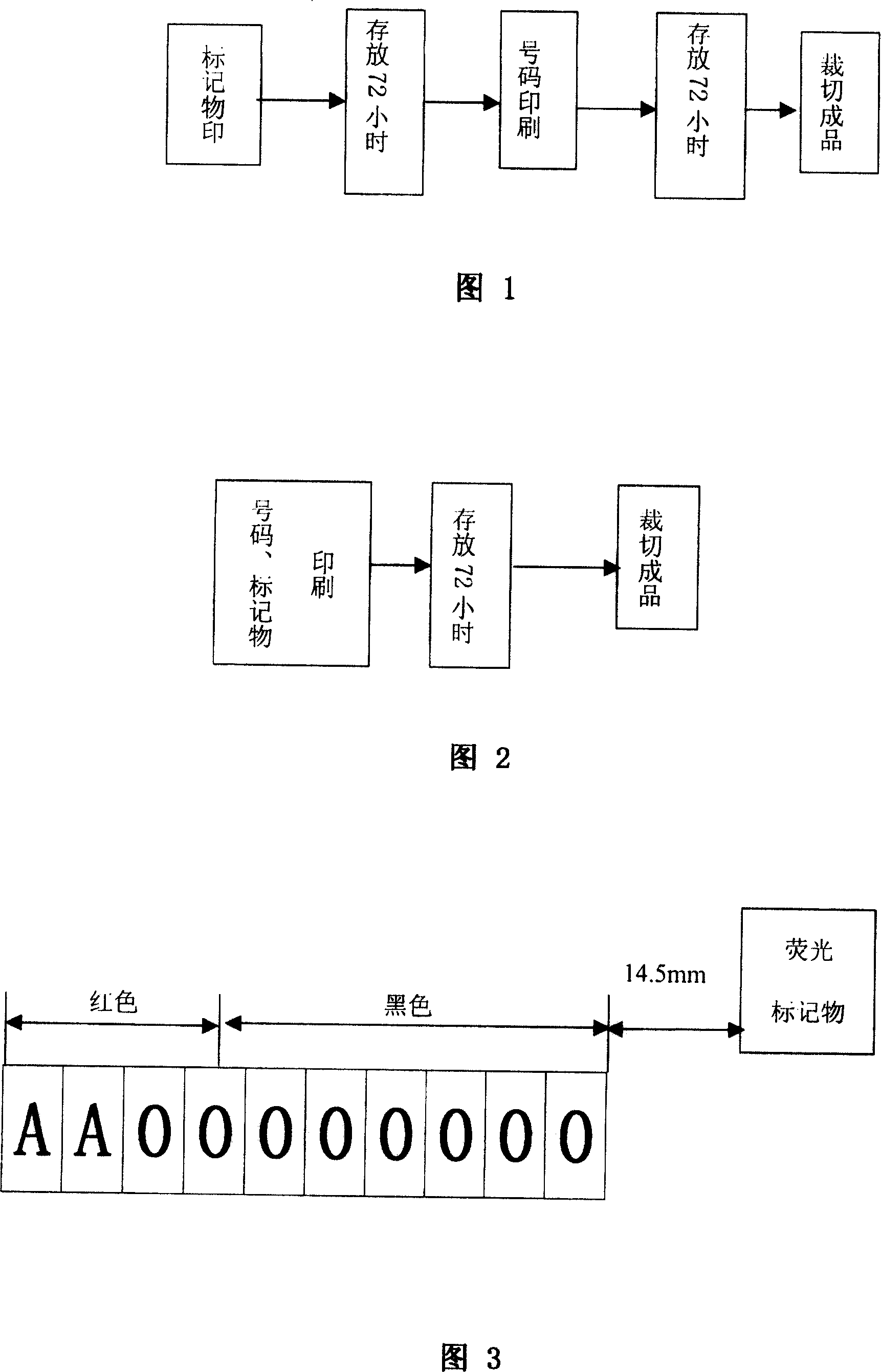

[0021] The number printing of the present invention is a single-code two-color connection, and there is no white seam or color shifting at the fourth digit of the number. It controls the movement amount of the ink shifting roller and the slit precision of the lower ink shifting roller within a certain tolerance range. to realise. Therefore, the present invention changes the original fixed ink channeling mechanism into an adjustable ink channeling mechanism. The design concept is a double eccentric mechanism of eccentric sleeve and eccentric shaft. The movement of the machine is set to be continuously and accurately adjustable within the range of 0-12mm. The movement of the ink roller can be adjusted according to the actual printing requirements of the product. For example, if the product number is printed with a single-code two-color connection, the first 3.6 digits are red, and the last 6.4 digits are magnetic. Black, the minimum distance between the number and the fluorescen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com