Oxygen enrichment device

A technology of enrichment and oxygen, which is applied in the direction of gasification material, respirator, household heating, etc., can solve problems such as large vibration, achieve the effect of low noise and improved positioning structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

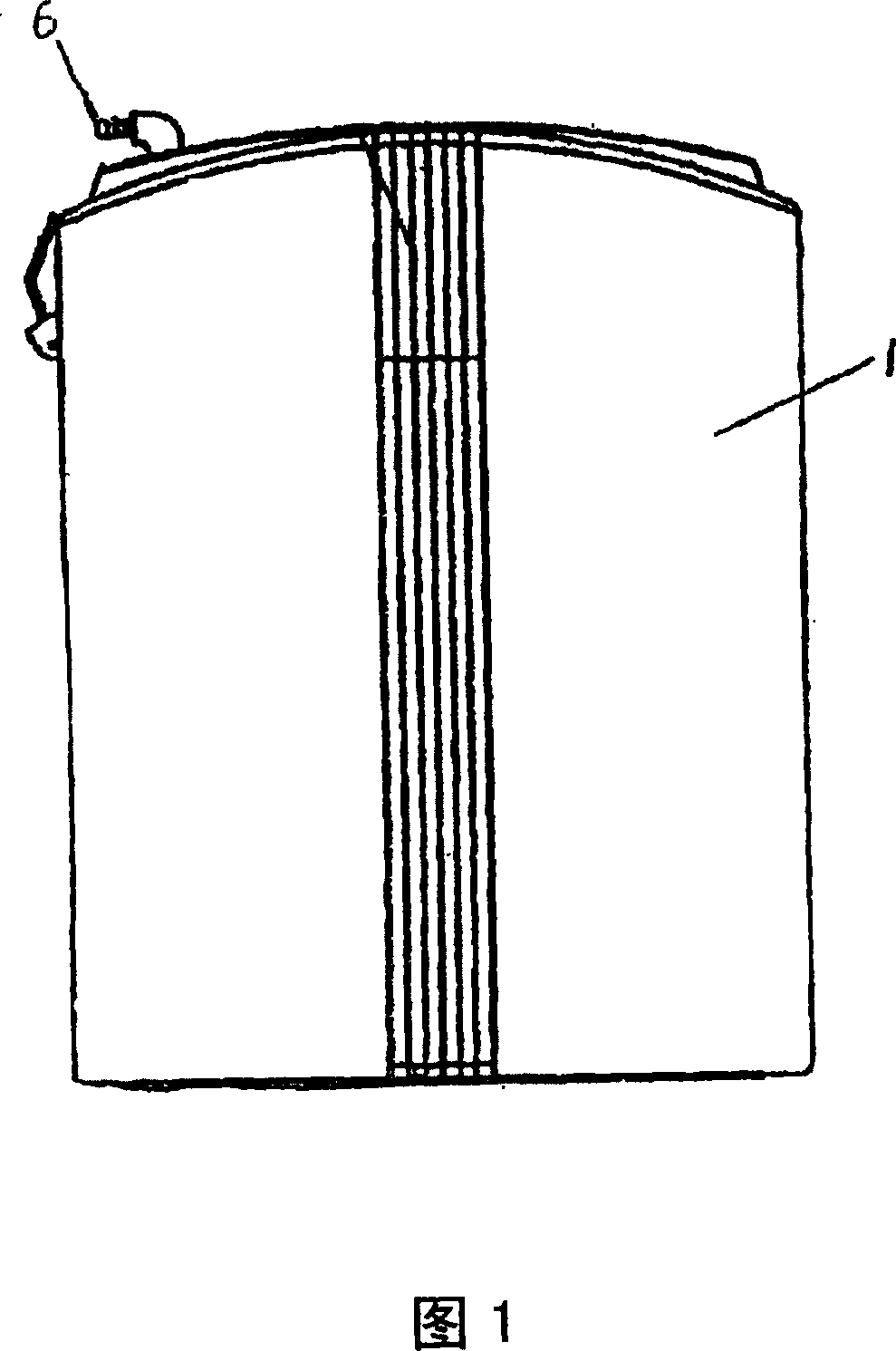

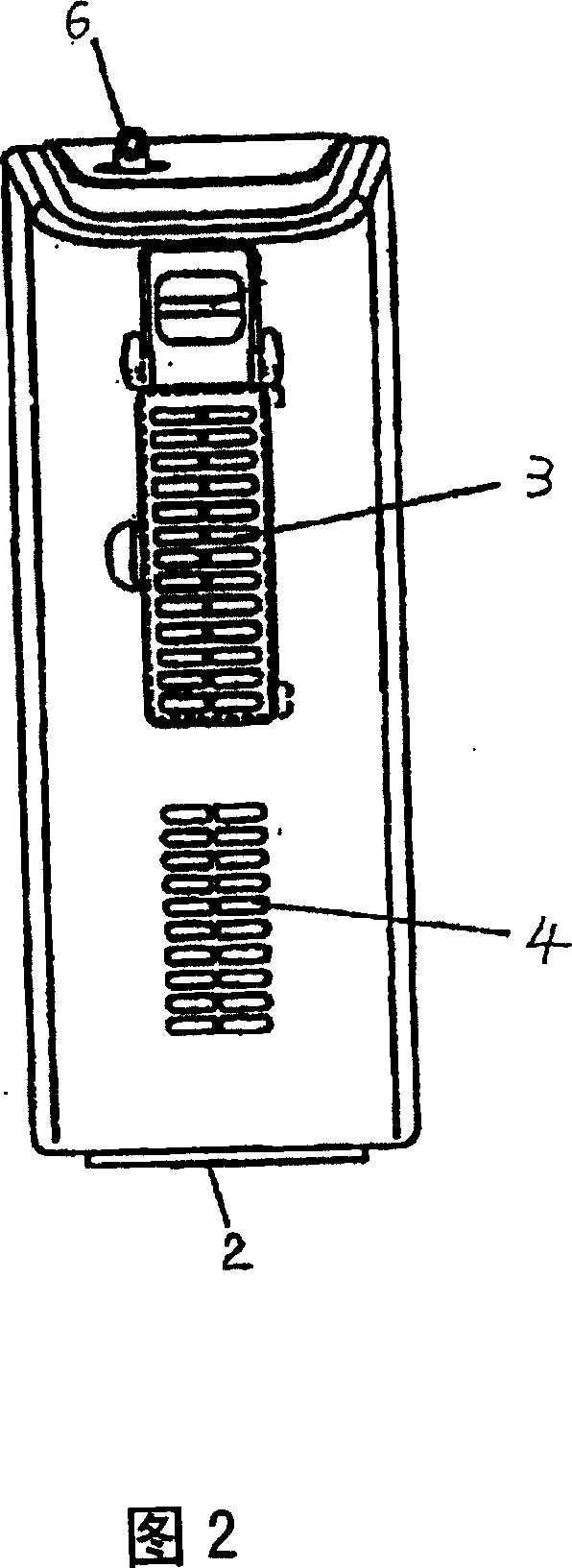

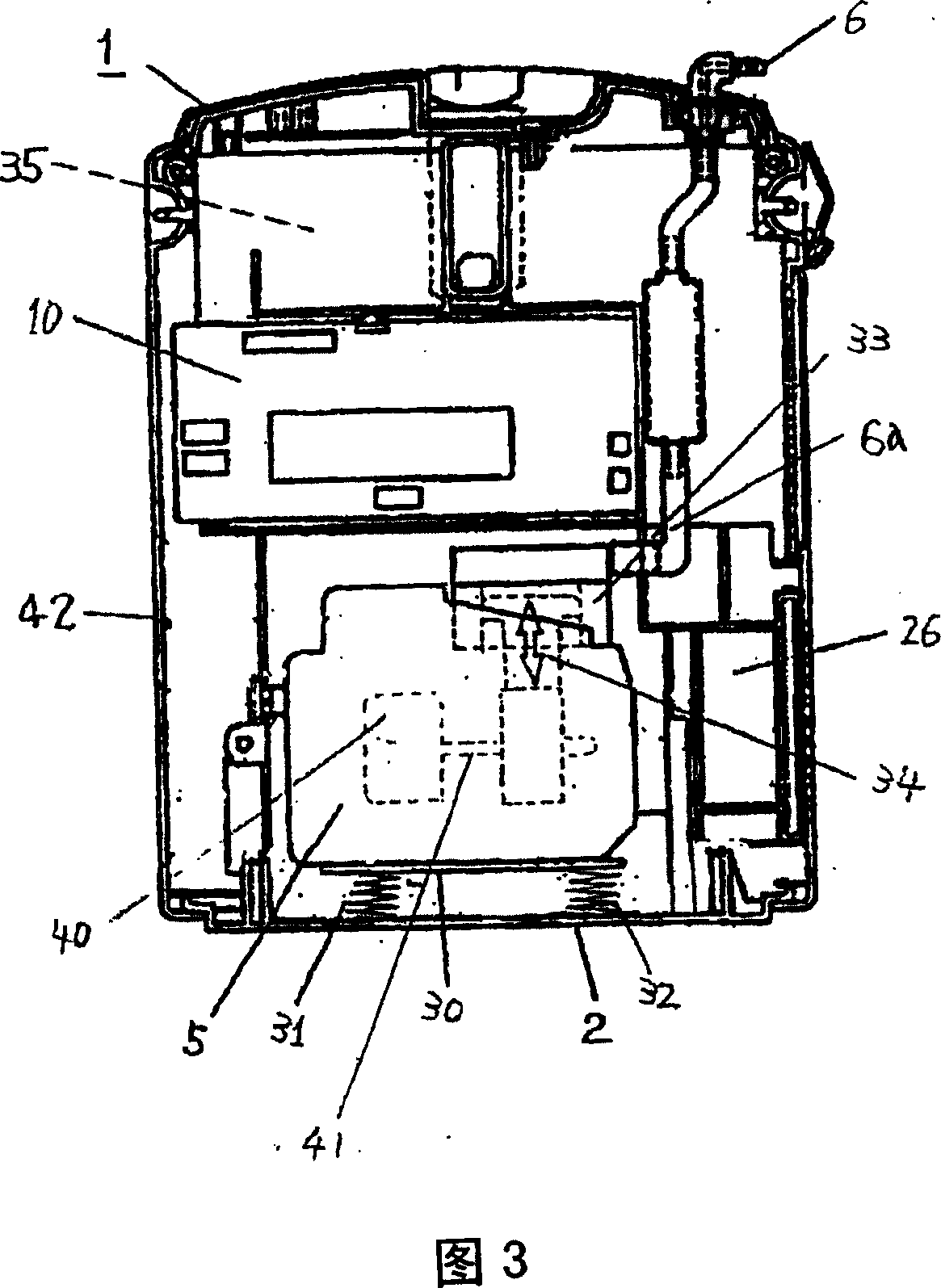

[0023] Some embodiments of the present invention will be described in detail below with reference to FIGS. 1 to 10 . It should be noted that the technical scope of the present invention is not limited by these examples.

[0024] As shown in Figures 1 to 5, an oxygen enrichment device, that is, an oxygen enrichment membrane module 35, is provided inside the oxygen enricher body 1 (hereinafter referred to as "body 1"), and the oxygen enrichment membrane module 35 is used for Oxygen-enriched air is generated by increasing the oxygen concentration in the air sucked into the living body 1 by an inhalation device 26 described later. After the air passes through the oxygen-enriched membrane module 35, the oxygen concentration in the air increases by about 30% (about 70% of nitrogen) from the normal concentration of 21% (about 79% of nitrogen) before passing through.

[0025] In addition, an air suction device 26 is also provided inside the body 1, and the air suction device 26 sucks...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com