Steam heater

A steam heater, a pair of technology, applied in the direction of air heater, fluid heater, steam separation device, etc., can solve the problem of normal drainage of condensed water, insufficient exchange of steam and plate adding device, heater temperature Insufficient compensation and other problems to achieve the effect of ensuring normal working conditions, improving positioning structure, and increasing thermal energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

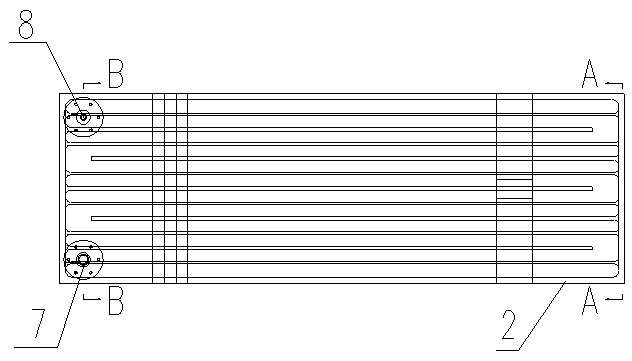

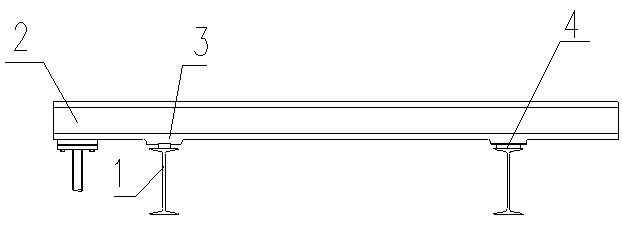

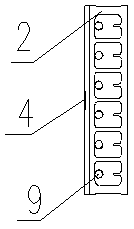

[0012] Such as figure 1 As shown, the present invention is composed of a pair of support bases 1 and a cavity 2, and the bottom of the cavity 2 is respectively provided with a transverse positioning surface 3 and a longitudinal positioning surface 4, and the bottoms of the two positioning surfaces are respectively provided with grooves, and the cavity The body 2 is horizontally installed on the support seat 1 through the horizontal positioning surface 3 and the longitudinal positioning surface 4, and is positioned by the groove stop on the horizontal positioning surface 3 and the longitudinal positioning surface 4. A group of partitions 5 are arranged in the cavity 2 , a group of partitions 5 respectively divide the container into a group of chambers, and each chamber communicates end to end, with ribs 6 on the top of each chamber, and steam inlets 7 on the bottom side of the chamber 2 and the condensed water outlet 8, the steam inlet 7 and the condensed water outlet 8 are res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com